Compound bismuthyl bromide photocatalyst

A photocatalyst, bismuth oxybromide technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low catalytic activity of visible light, narrow visible light response, limited visible light absorption, etc. Achieve the effect of wide photoresponse range, good photocatalytic ability and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

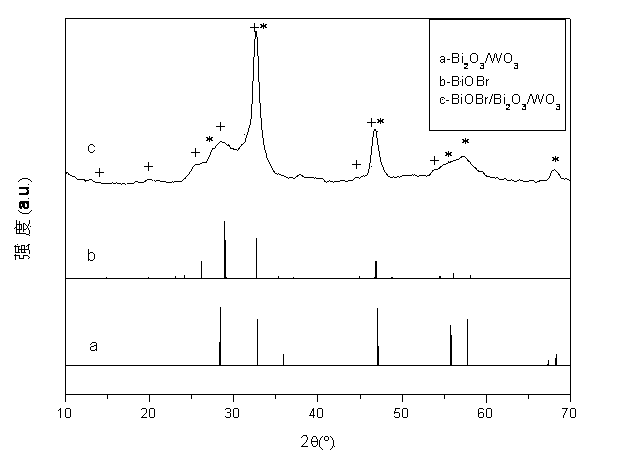

[0017] Sinopharm bismuth nitrate pentahydrate (Bi(NO3)3 5H2O) 1.3485g was dissolved in 40ml water, stirred at room temperature until a homogeneous solution A was formed, and 0.5467g cetyltrimethylammonium bromide (CTAB) and 0.3581g di Sodium tungstate hydrate (Na2WO4·2H2O), dissolved in 40ml water and stirred at room temperature until solution B was formed. Slowly drop solution A into solution B at a rate of 30 drops per minute, so that the molar ratio of reactants is Bi(NO3)3·5H2O:CTAB:Na2WO4·2H2O=2.78:1.5:1. After the mixture was stirred at room temperature for 30 minutes, it was transferred to a polytetrafluoroethylene kettle at 130°C for 18 hours of hydrothermal reaction, and after suction filtration, it was dried at 80°C for 12 hours. Get BiOBr / Bi 2 o 3 / WO 3 Composite photocatalytic materials. according to figure 2 -c, the sample obtained in Example 1 contains the characteristic diffraction peaks of BiOBr and Bi2O3 / WO3.

Embodiment 2

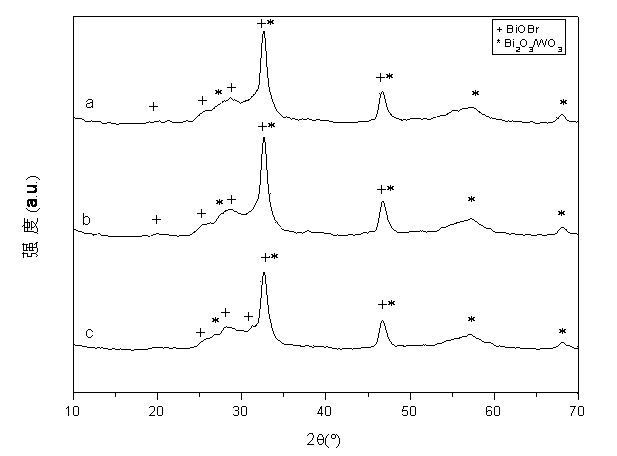

[0019] In the above-mentioned Example 1, the usage amount of cetyltrimethylammonium bromide was changed to 1.0132 g, and other conditions remained unchanged. Preparation of BiOBr / Bi2O3 / WO3 composite photocatalytic materials. according to figure 1 -a, the sample obtained in Example 2 contains BiOBr and Bi2O3 / WO3 crystal forms.

Embodiment 3

[0021] In the above example 1, the optimum ratio (Bi(NO3)3·5H2O:CTAB:Na2WO4·2H2O molar ratio is 2.78:1.5:1) was used, the hydrothermal temperature was changed to 100°C, and other conditions remained unchanged. Preparation of BiOBr / Bi2O3 / WO3 composite photocatalytic materials. according to figure 1 -b, the sample obtained in Example 3 contains BiOBr and Bi2O3 / WO3 crystal forms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com