A supersonic flame spraying type flux-cored welding wire and its preparation method

A technology of supersonic flame and flux-cored wire, applied in welding equipment, welding medium, manufacturing tools, etc., can solve the problems of unfavorable molten pool gas escape, many pores on the surface of the weldment, and unsatisfactory performance, and achieve simple structure , Welding spatter is small, the effect of welding speed is fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

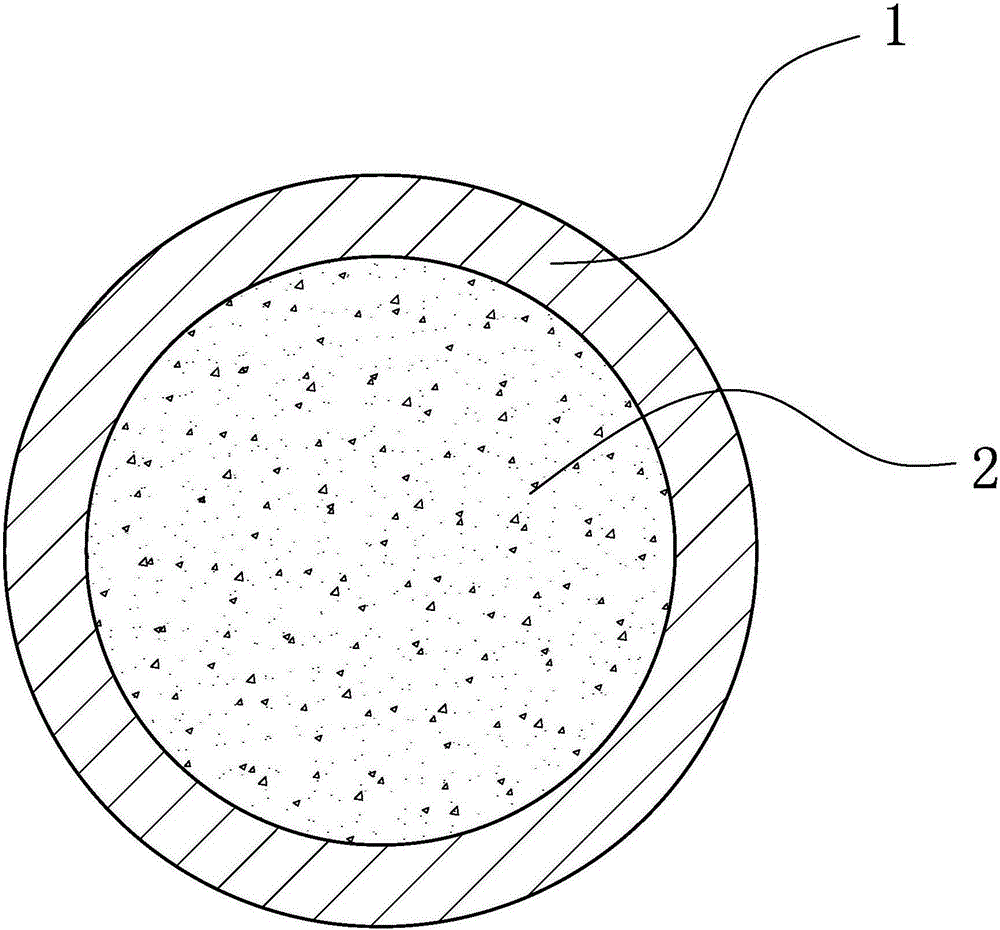

Image

Examples

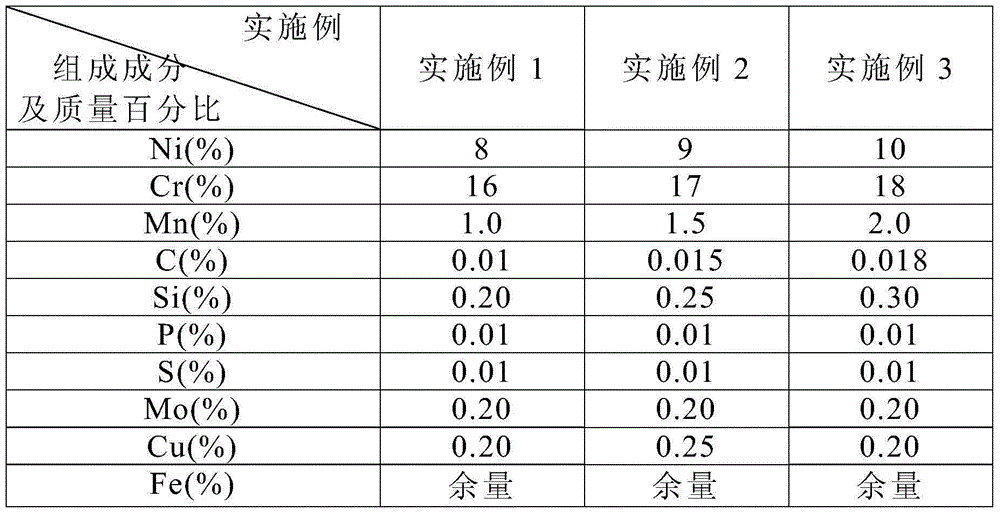

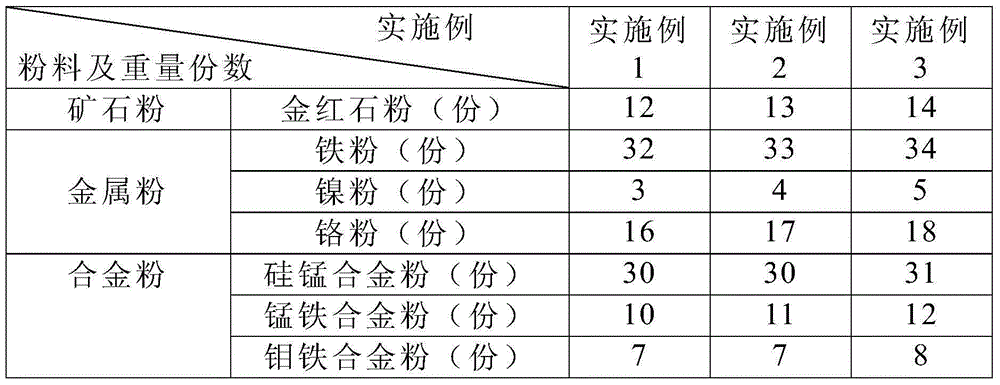

Embodiment 1

[0041] First, the powder was weighed according to the powder and parts by weight of the drug core powder in Example 1 in Table 2, and the powder was sieved once through an 80-mesh sieve and then fully mixed to prepare the drug core powder. According to the composition and mass percentage of the steel strip in Example 1 in Table 1, the thickness is 0.5mm, and the steel strip with a width of 260mm is rolled into a U-shaped groove structure, and in the U-shaped groove, add 17% of flux-cored wire gross weight The medicine core powder prepared above. Then use a molding machine to close the U-shaped groove and form a through hole through the steel strip along the axial direction of the steel strip, and the drug core powder is wrapped in the through hole. Finally, the steel strip wrapped with flux core powder is drawn and reduced one by one by a wire drawing machine to make the diameter reach 1.2mm, and the final product supersonic flame sprayed flux cored wire is obtained.

Embodiment 2

[0043] First, the powder was weighed according to the powder and parts by weight of the drug core powder in Example 2 in Table 2, and the powder was screened once through a 100-mesh sieve and then fully mixed to prepare the drug core powder. According to the composition and mass percentage of the steel strip in Example 2 in Table 1, the thickness is 0.6mm, and the steel strip with a width of 280mm is rolled into a U-shaped groove structure, and in the U-shaped groove, add 18% of flux-cored wire gross weight The medicine core powder prepared above. Then use a molding machine to close the U-shaped groove and form a through hole through the steel strip along the axial direction of the steel strip, and the drug core powder is wrapped in the through hole. Finally, the steel strip wrapped with flux core powder is drawn and reduced in diameter through a wire drawing machine, so that its diameter reaches 1.3 mm, and the final product supersonic flame sprayed flux cored wire is obtaine...

Embodiment 3

[0045] First, the powder was weighed according to the powder and parts by weight of the drug core powder in Example 3 in Table 2, and the powder was screened twice through a 120-mesh sieve and then fully mixed to prepare the drug core powder. According to the composition and mass percentage of the steel strip in Example 3 in Table 1, the thickness is 0.7mm, and the steel strip with a width of 300mm is rolled into a U-shaped groove structure, and in the U-shaped groove, add 19% of flux-cored wire gross weight The medicine core powder prepared above. Then use a molding machine to close the U-shaped groove and form a through hole through the steel strip along the axial direction of the steel strip, and the drug core powder is wrapped in the through hole. Finally, the steel strip wrapped with flux core powder is drawn and reduced one by one by a wire drawing machine, so that its diameter reaches 1.4mm, and the final product supersonic flame sprayed flux cored wire is obtained.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com