Industrial device and treatment method for treating coal-gasification ammonia nitrogen wastewater by synchronous nitrification and denitrification

A technology for synchronous nitrification and industrial equipment, applied in chemical instruments and methods, aerobic and anaerobic process treatment, water/sludge/sewage treatment, etc., can solve problems such as limited application, shorten reaction time, and reduce infrastructure costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

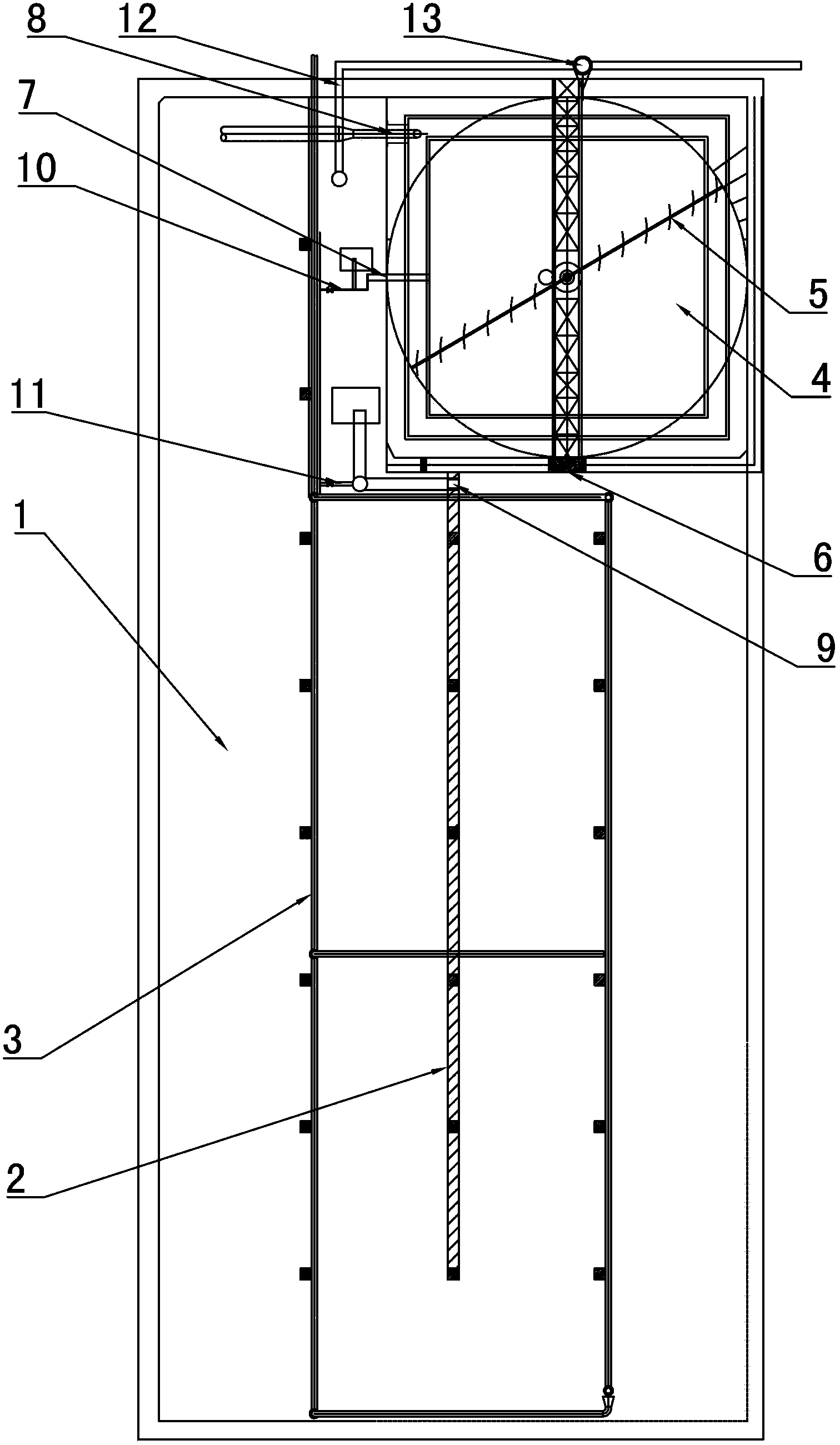

[0028] Figure 1~6 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~6 The present invention is described further:

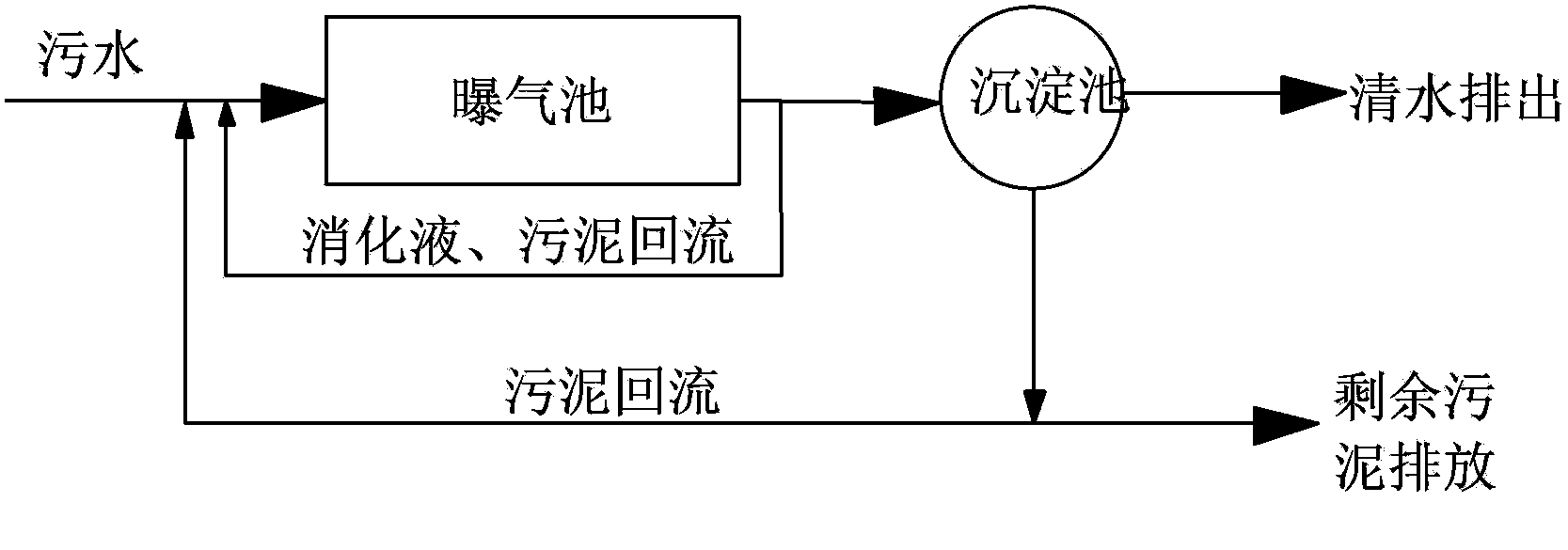

[0029] Refer to attached figure 1 : The industrial device for synchronous nitrification and denitrification treatment of coal gasification ammonia nitrogen sewage, comprising a rectangular aeration tank 1 and a sewage pipe 12 leading into the aeration tank 1, the aeration tank 1 is covered with a cement cover plate, and the sewage pipe 12 The function is to introduce sewage into the aeration tank 1 , and an electromagnetic flowmeter 13 is installed in the sewage pipe 12 . There are multiple aeration pipes 3 distributed in the aeration tank 1. The area where the aeration pipes 3 are located is the reaction zone. A sedimentation tank 4 is built in one corner of the aeration tank 1. A mud scraper 5 is installed in the sedimentation tank 4. The sedimentation tank 4 There is a backflow port 7 and a drain port 8 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com