A method for starting and controlling partial nitrosation

A control method and nitrification technology, applied in chemical instruments and methods, anaerobic digestion treatment, water/sludge/sewage treatment, etc., can solve the problem of unstable effluent nitrogen ratio, difficulty in maintaining and continuous sludge concentration in the system In order to achieve the effects of low energy consumption of aeration and fluidization, high oxygen utilization rate and adjustable volume load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

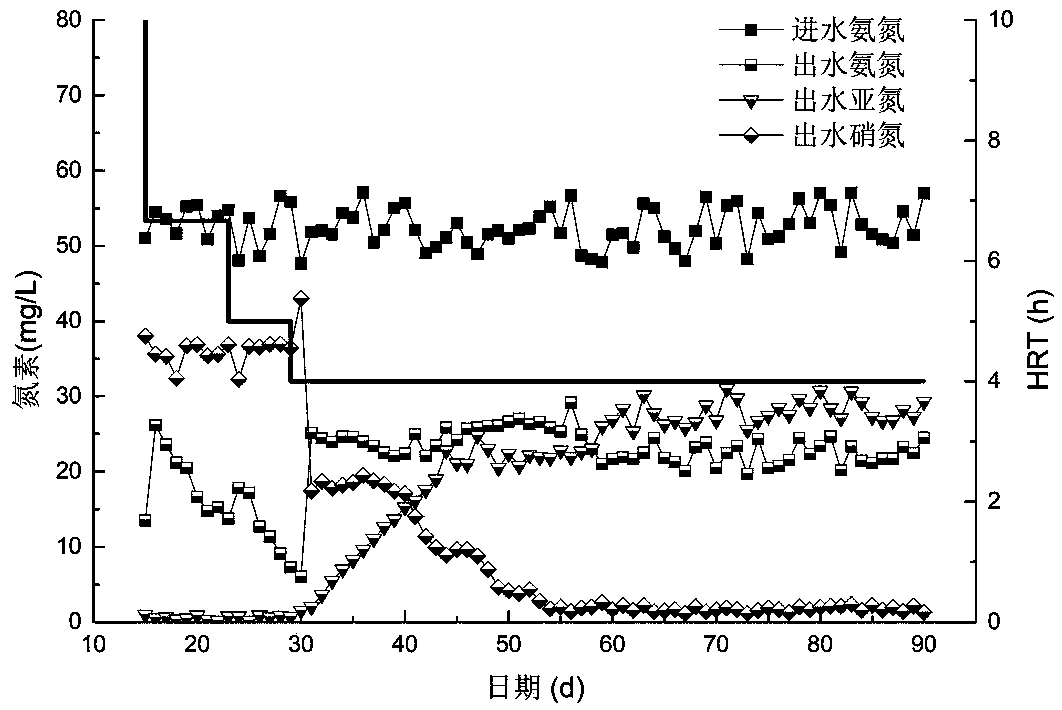

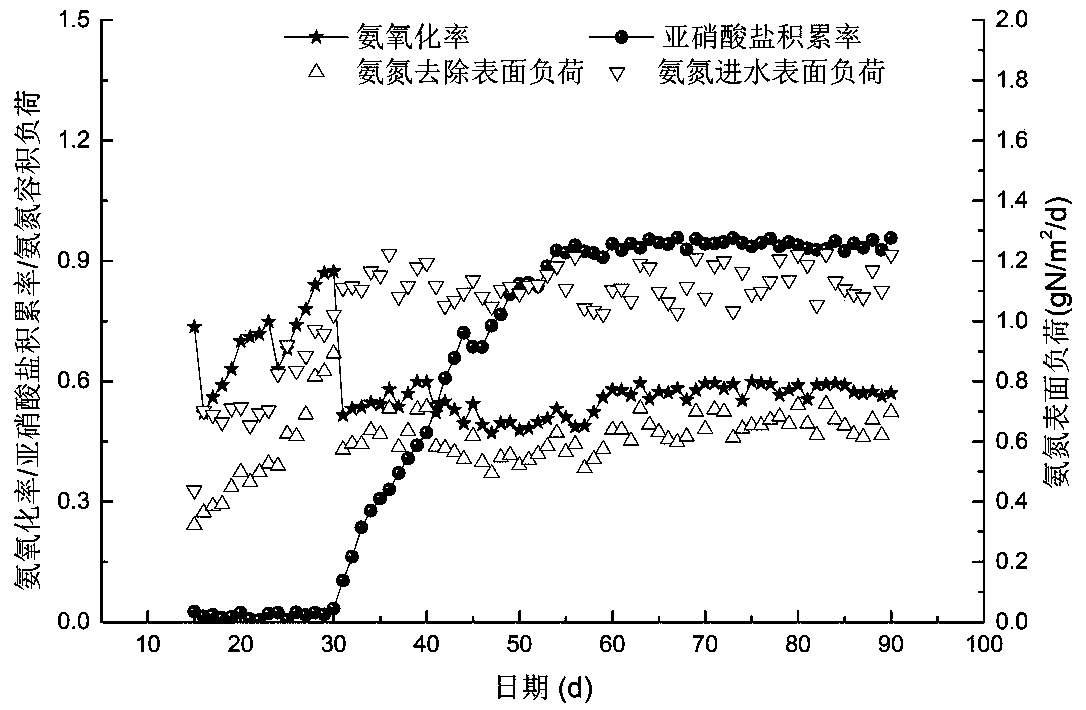

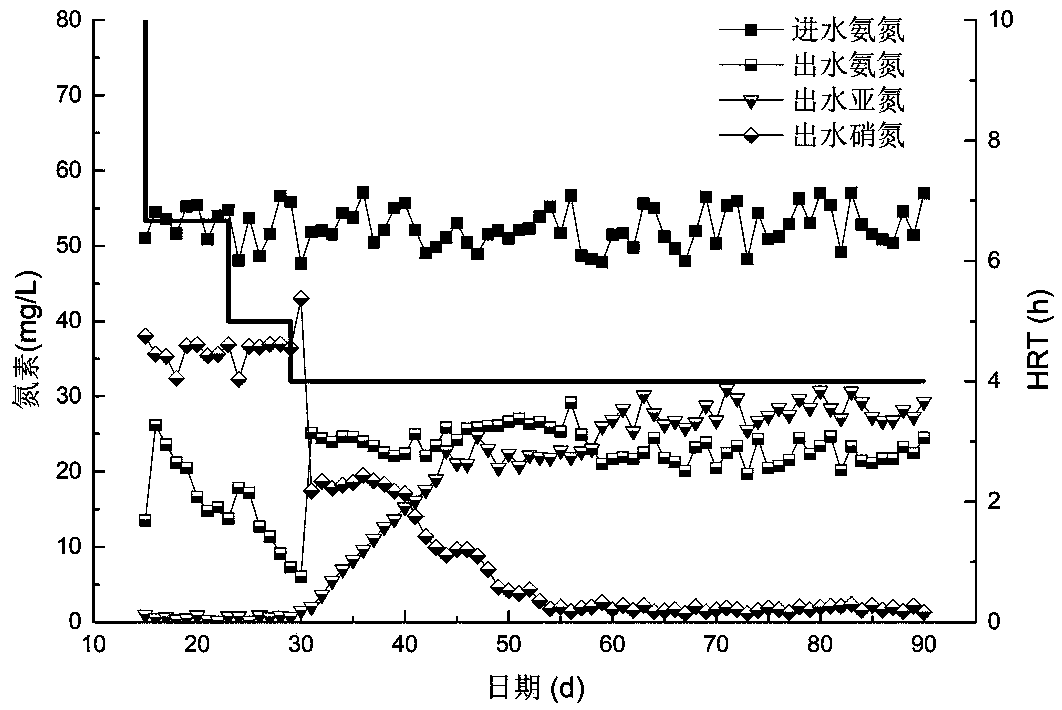

[0060] The reactor pool capacity is 10m 3 , using a specific surface area of 700m 2 / m 3 Suspended carrier, the specific gravity of the suspended carrier is 0.965 before the membrane is attached, and the porosity is >95%; the reactor is not equipped with sludge reflux, and the suspended sludge concentration in the reactor is always <0.5g / L during the continuous flow operation; domestic sewage is used as the feed water For decarbonized sewage, the influent BOD is 10±3mg / L, the TN is 55±6mg / L, the ammonia nitrogen is 50±5mg / L, BOD:TN<0.2, the influent SS<20mg / L, and the water temperature is 15± 3°C;

[0061] 1) Start nitrification, fill suspension carrier 4m 3 , the filling rate is 40%, the DO is controlled at 4-5mg / L, and the activated sludge of the sewage plant is inoculated with 4g / L. Sludge, start continuous water inflow and aeration, initial HRT=10h, DO control at 4-5mg / L, by 15d, ammonia oxidation rate is 74%, ammonia nitrogen removal surface load is 0.322gN / (m 2 d)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com