Biotreatment method for efficiently purifying biogas slurry with microalgae

A biological treatment and microalgae technology, which is applied in biological water/sewage treatment, chemical instruments and methods, biofuels, etc., can solve problems not involved in microalgae treatment and achieve good market promotion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

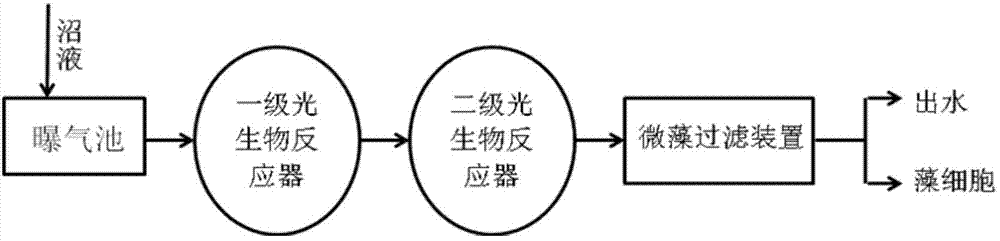

Embodiment 1

[0019] Using straw and pig manure as raw materials, biogas slurry is produced after fermentation. The COD in the biogas slurry is 3500-3800mg / L, the TN is 250-300mg / L, and the TP is 120-150mg / L. Flow the above biogas slurry into the aeration tank, add activated sludge for aeration pretreatment, the aeration time is 15h, and the standing time is 10h. After the aeration pretreatment, the biogas slurry flows into the filter screen of the aeration tank First-level photobioreactor, microalgae are inoculated in the first-level photobioreactor, and the temperature of the reactor is 27°C and cultivated for 6 days. After most of the pollutants are degraded, the wastewater enters the second-level photobioreaction The sewage containing microalgae is reacted at the reactor temperature of the secondary photobioreactor at 27°C for 5 days, relying on the action of the microalgae to degrade the pollutants, and the nitrogen and phosphorus degradation rate reaches more than 80%. The algae waste...

Embodiment 2

[0021] Using straw and pig manure as raw materials, biogas slurry is produced after fermentation. The COD in the biogas slurry is 3500-3800mg / L, the TN is 250-300mg / L, and the TP is 120-150mg / L. Flow the above biogas slurry into the aeration tank, add activated sludge for aeration pretreatment, the aeration time is 10h, and the standing time is 8h. After the aeration pretreatment, the biogas slurry flows into the aeration tank after passing through the filter screen First-level photobioreactor, inoculate microalgae in the first-level photobioreactor, and cultivate it for 5 days at the temperature of the reactor at 25°C. After most of the pollutants are degraded, the wastewater enters the second-level photobioreaction The sewage containing microalgae is reacted at the reactor temperature of the secondary photobioreactor at 25°C for 4 days, relying on the action of microalgae to degrade the pollutants, and the nitrogen and phosphorus degradation rate reaches more than 80%. The a...

Embodiment 3

[0023] Using straw and pig manure as raw materials, biogas slurry is produced after fermentation. The COD in the biogas slurry is 3500-3800mg / L, the TN is 250-300mg / L, and the TP is 120-150mg / L. The above biogas slurry is flowed into the aeration tank, and activated sludge is added for aeration pretreatment. The aeration time is 18 hours, and the standing time is 12 hours. After the aeration pretreatment, the biogas slurry flows into the filter screen of the aeration tank First-level photobioreactor, microalgae are inoculated in the first-level photobioreactor, and the temperature of the reactor is 30°C and cultivated for 8 days. After most of the pollutants are degraded, the wastewater enters the second-level photobioreaction The sewage containing microalgae is reacted at the reactor temperature of the secondary photobioreactor at 30°C for 7 days, relying on the action of microalgae to degrade the pollutants, and when the degradation rate of nitrogen and phosphorus reaches mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com