Gradual treatment and recovery method for secondary treatment effluent of printing and dyeing wastewater

A technology for secondary treatment of effluent and printing and dyeing wastewater, which is applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., and can solve the problem that the secondary effluent treatment effect is not ideal Cooperate with other issues to achieve the effect of low waste water treatment cost, economical reuse and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

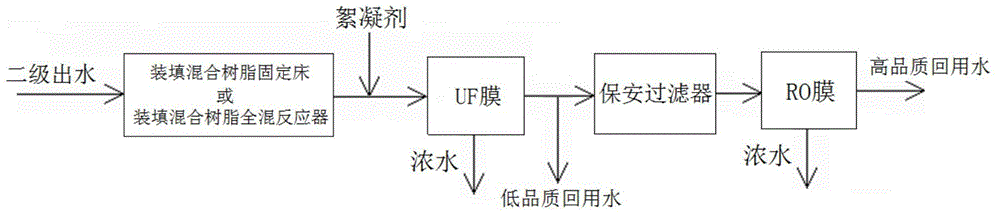

[0032] In conjunction with the accompanying drawings, the specific steps of the stepwise treatment and reuse method of the secondary treatment effluent of printing and dyeing wastewater in this embodiment are as follows:

[0033](1) Fill 8mL mixed ion exchange resin in a glass adsorption column with a diameter of 1cm and a height of 20cm (the effect is the same as that of a fixed bed reactor), of which 1.6mL is macroporous strong acid styrene-based cation exchange resin D001, functional group The group is a sulfonic acid group (-SO 3 H); 6.4mL is a macroporous strong base type acrylic anion exchange resin D213, the two resins are evenly mixed, and the particle size is between 0.5-1.00mm. Pass the secondary effluent of the printing and dyeing wastewater whose water quality is shown in Table 1 through the ion exchange column (namely the glass adsorption column) for exchange reaction, and the flow rate of the secondary effluent is 10BV / h. When the ion exchange column outlet Ca ...

Embodiment 2

[0044] The cascade treatment and reuse method of the effluent from the secondary treatment of printing and dyeing wastewater in this example is basically the same as in Example 1, except that the granular macroporous strong-acid styrene-based cation exchange resin D001 and large Porous strong base type acrylic anion exchange resin D213 was replaced by microspherical macroporous weak acid type acrylic type cation exchange resin D113 and macroporous strong base type acrylic anion exchange resin D213 with a particle size of 80-100 μm, macroporous strong base type The volume ratio of the acrylic anion exchange resin and the macroporous weak acid type acrylic cation exchange resin is 3:1; the two resins are evenly mixed. The reactor was changed to a fully mixed reactor, the stirring speed in the fully mixed reactor was 150rpm, and the reaction time was 30min. 2+ The concentration is 1.5mg / L, the DOC is 6.2mg / L, and the SDI value is 0.52; the ultrafiltration effluent is filtered wit...

Embodiment 3

[0046] The cascade treatment and reuse method of the secondary treatment effluent of printing and dyeing wastewater in this embodiment is basically the same as in embodiment 1, the difference is that in this embodiment, the mixed ion exchange resin is a macroporous strong alkali type with a volume ratio of 5:1 Acrylic anion exchange resin D213 and macroporous weak acid type acrylic cation exchange resin D113, the two resins are uniformly mixed, and the particle size is between 0.8-1.25mm, the flow rate of the secondary outlet water is 2BV / h, the added inorganic The flocculant is polyaluminum chloride, and the concentration of polyaluminum chloride in the effluent is 10mg / L. In the ultrafiltration treatment, the polyethersulfone membrane with a cut molecular weight of 50kDa is used for the ultrafiltration membrane, and the mass percentage concentration of the desorption solution is 10%. of NaCl solution. The secondary effluent of the printing and dyeing wastewater in this embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com