Method for extracting zeaxanthine from physalis alkekengi and fruits through one-pot method

A technology of zeaxanthin and brocade lanterns, applied in the direction of organic chemistry, can solve the problems of limited zeaxanthin resources, achieve good application prospects, simplify the production process, and achieve high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

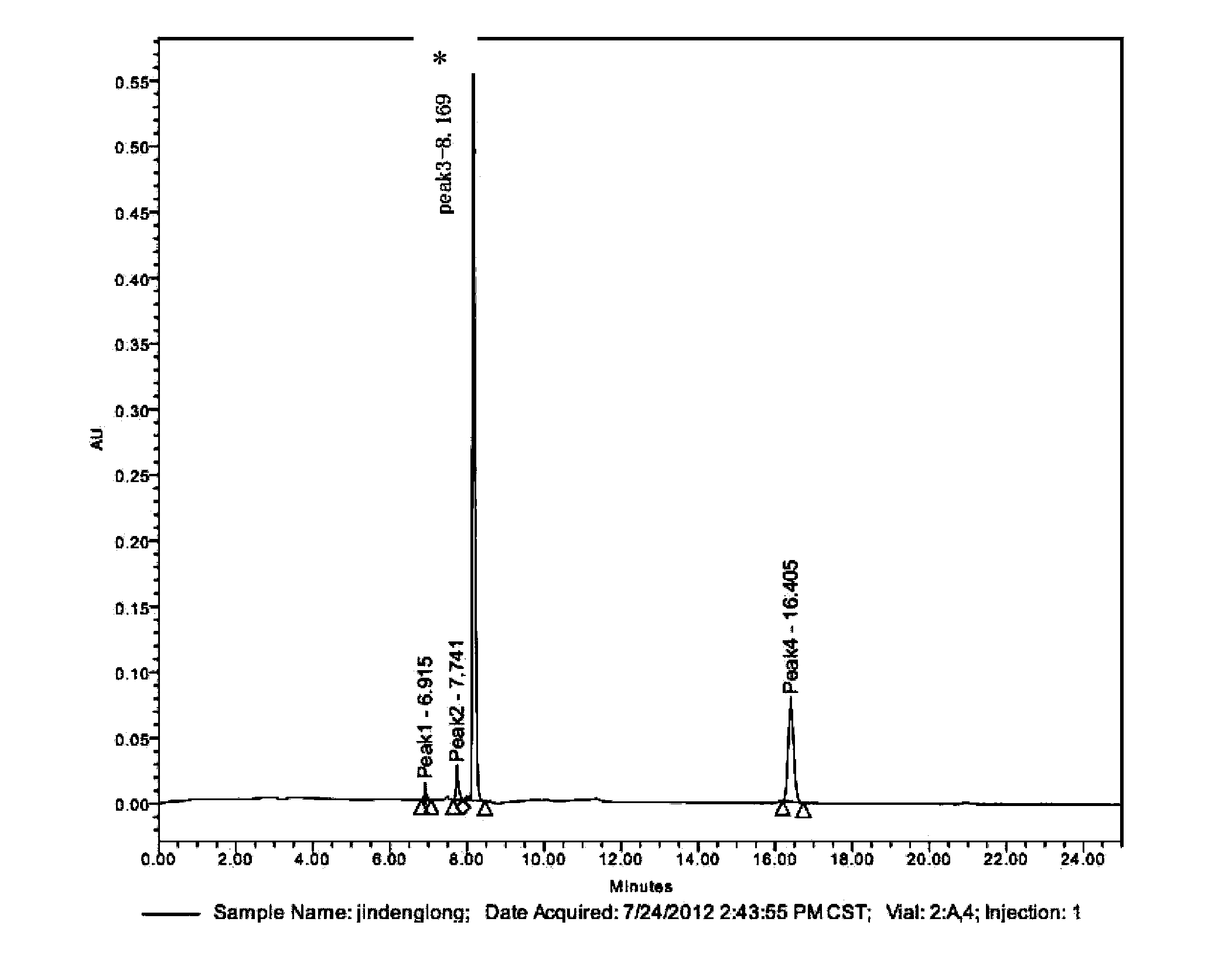

[0029] Using the fruit of Jindenglong as raw material, zeaxanthin was prepared according to the following process:

[0030] Take 1000 grams of Jindeng fruit, freeze-dry, grind into powder, pass through a 100-mesh sieve, take the powder under the sieve, add ethanol-cyclohexane solution containing 10% KOH in mass concentration according to the ratio of Jindeng quality: solvent volume = 1g: 10ml (Ethanol: non-polar organic solvent volume ratio 1:1) 10 liters, stirred at 30°C for extraction and saponification for 2 hours; after the extraction, set aside to settle and separate; obtain the extract and filter residue;

[0031] Add 10 liters of the above ethanol-cyclohexane solution containing 10% KOH to the filter residue again for the second extraction and saponification; stir extraction and saponification at 30°C for 2 hours; stand for precipitation and separation after extraction; obtain the extract and filter residue;

[0032] Add 10 liters of the above ethanol-cyclohexane soluti...

Embodiment 2

[0036] Using Jindenglong Persistent Calyx as raw material, zeaxanthin was prepared according to the following process:

[0037] Take 1000 grams of persistent calyx, freeze-dry, grind into powder, pass through a 100-mesh sieve, take the powder under the sieve, add ethanol-cyclohexane solution containing mass concentration 10% KOH according to the ratio of persistent calyx mass:solvent volume=1g:50ml ( Ethanol: non-polar organic solvent (volume ratio 1:1) 50 liters, 30 ° C stirring extraction, saponification for 2 hours; after the extraction, set aside to precipitate and separate; obtain the extract and filter residue;

[0038] Add 50 liters of the above ethanol-cyclohexane solution containing 10% KOH to the filter residue again for the second extraction and saponification; stir extraction and saponification at 30°C for 2 hours; after the extraction, let it stand for precipitation and separation; obtain the extract and filter residue;

[0039] Add 10 liters of the above ethanol-cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com