Preparing method and refining method for milrinone

A refining method and technology of milrinone are applied in the preparation method and refining field of milrinone, and can solve the problems of large amount of solvent, difficult operation, poor product quality, etc., so as to reduce production cost, improve product quality and yield, Easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

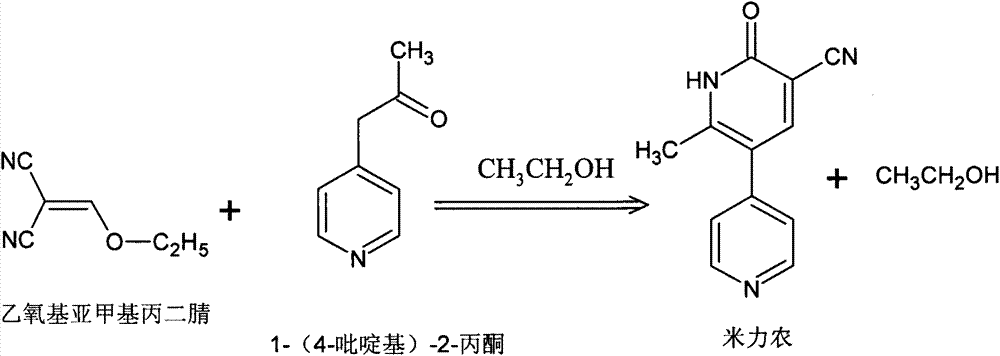

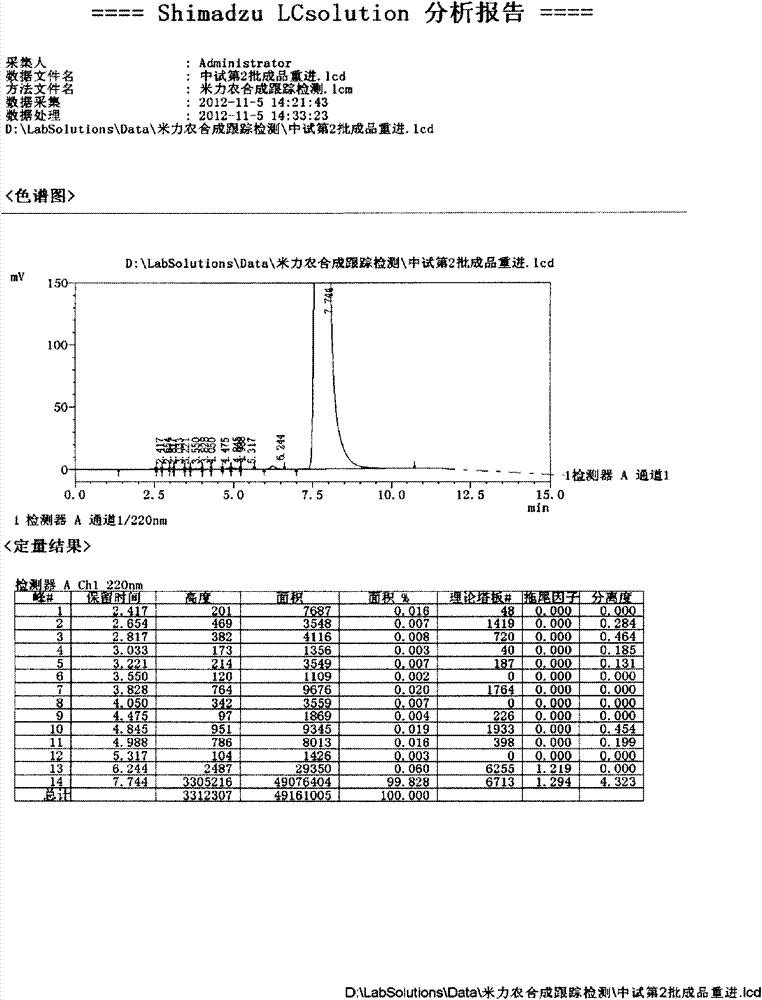

[0022] Example 1 Milrinone preparation

[0023] In a 150L reactor, add 6.9Kg (56.55mol) of ethoxymethylenemalononitrile and 36Kg of absolute ethanol, stir, and raise the temperature to about 40℃ until all ethoxymethylenemalononitrile is dissolved ; Add 6Kg (44.37mol) 1-(4-pyridyl)-2-acetone in anhydrous ethanol solution dropwise, after dripping, keep for 1.5h, then warm up to 80 ℃ for reflux, keep for 4h, until the reaction is over, stir , The reaction liquid was cooled to 40°C, solid-liquid separation, and solids were collected to obtain 12.9Kg of dark red milrinone crude wet material. The synthesis yield was about 84%.

Embodiment 2

[0024] Example 2 Milrinone's primary purification

[0025] In a 100L reactor, add 12.9Kg of milrinone crude wet material and 39Kg of drinking water, stir, heat up to about 65℃, adjust pH=1 with concentrated HCl, and add 1.29Kg of activated carbon and stir for 5 -10 minutes, filter while hot, collect the filtrate, stir, cool to 0-5°C to crystallize, collect the solid, and obtain 10.8Kg of milrinone primary refined product wet material.

Embodiment 3

[0026] Example 3 Milrinone's secondary purification

[0027] In a 50L reactor, add 10.8Kg of milrinone primary refined product wet material and 33Kg of drinking water, stir, heat up to 80-100℃, until all dissolved, stir, cool to 0-5℃ to crystallize, collect solids, 7.5Kg of milrinone second refined product wet material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com