High-strength adhesive as well as preparation method and application thereof

An adhesive, high-strength technology, used in adhesives, polymer adhesive additives, surface pretreatment bonding methods, etc., can solve the problems of high rigidity and brittleness, poor bonding strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0117] Embodiment 1: prepare high-strength adhesive

[0118] The implementation steps of this embodiment are as follows:

[0119] (i) Raw materials used to prepare high-strength adhesives:

[0120] 830 modified aromatic amine curing agent is a product sold by Huntsman under the tradename Aradur 830.

[0121] 850 modified aromatic amine curing agent is a product sold by Huntsman under the tradename Aradur 850.

[0122] Bisphenol A epoxy resin is a product sold under the trade name D.E.R. 331 by The Dow Chemical Company.

[0123] (ii) Preparation of epoxy-terminated polyepichlorohydrin resin

[0124] A, the preparation of polyepichlorohydrin

[0125] Under the conditions of 0.1% boron trifluoride ethyl ether Lewis acid catalyst based on the weight of epichlorohydrin and a temperature of 60 ° C, according to the molar ratio of epichlorohydrin to ethylene glycol polyol 4:1, let epichlorohydrin and Polyhydric alcohols were polymerized for 8 hours to obtain polyepichlorohydrin;...

Embodiment 2

[0130] Embodiment 2: prepare high-strength adhesive

[0131] The implementation steps of this embodiment are as follows:

[0132] (i) Raw materials used in the preparation of high-strength adhesives:

[0133] 830 modified aromatic amine curing agent is a product sold by Huntsman under the tradename Aradur 830.

[0134] 850 modified aromatic amine curing agent is a product sold by Huntsman under the tradename Aradur 850.

[0135] Bisphenol F epoxy resin is sold under the trade name NPEF-170 by Nan Ya Epoxy Resin Co., Ltd.

[0136] (ii) Preparation of epoxy-terminated polyepichlorohydrin resin:

[0137] A, the preparation of polyepichlorohydrin

[0138] Under the conditions of 0.01% tin tetrachloride Lewis acid catalyst based on the weight of epichlorohydrin and a temperature of 40 ° C, according to the molar ratio of epichlorohydrin to glycerol polyol 600:1, let epichlorohydrin and polyhydric Alcohol was polymerized for 6 hours to obtain polyepichlorohydrin;

[0139] B, p...

Embodiment 3

[0143] Embodiment 3: prepare high-strength adhesive

[0144] The implementation steps of this embodiment are as follows:

[0145] (i) Raw materials used to prepare high-strength adhesives:

[0146] 830 modified aromatic amine curing agent is a product sold by Huntsman under the tradename Aradur 830.

[0147] 850 modified aromatic amine curing agent is a product sold by Huntsman under the tradename Aradur 850.

[0148] Novolac epoxy resin is a product sold under the tradename F-51 by Jiangsu Sanmu Chemical Co., Ltd.

[0149] (ii) Preparation of epoxy-terminated polyepichlorohydrin resin

[0150] A, the preparation of polyepichlorohydrin

[0151] Under the conditions of 1.0% aluminum trichloride Lewis acid catalyst based on the weight of epichlorohydrin and a temperature of 80 ° C, according to the molar ratio of epichlorohydrin to propylene glycol polyol 100:1, the reaction between epichlorohydrin and polyol is carried out. Polymerization for 4 hours to obtain polyepichlor...

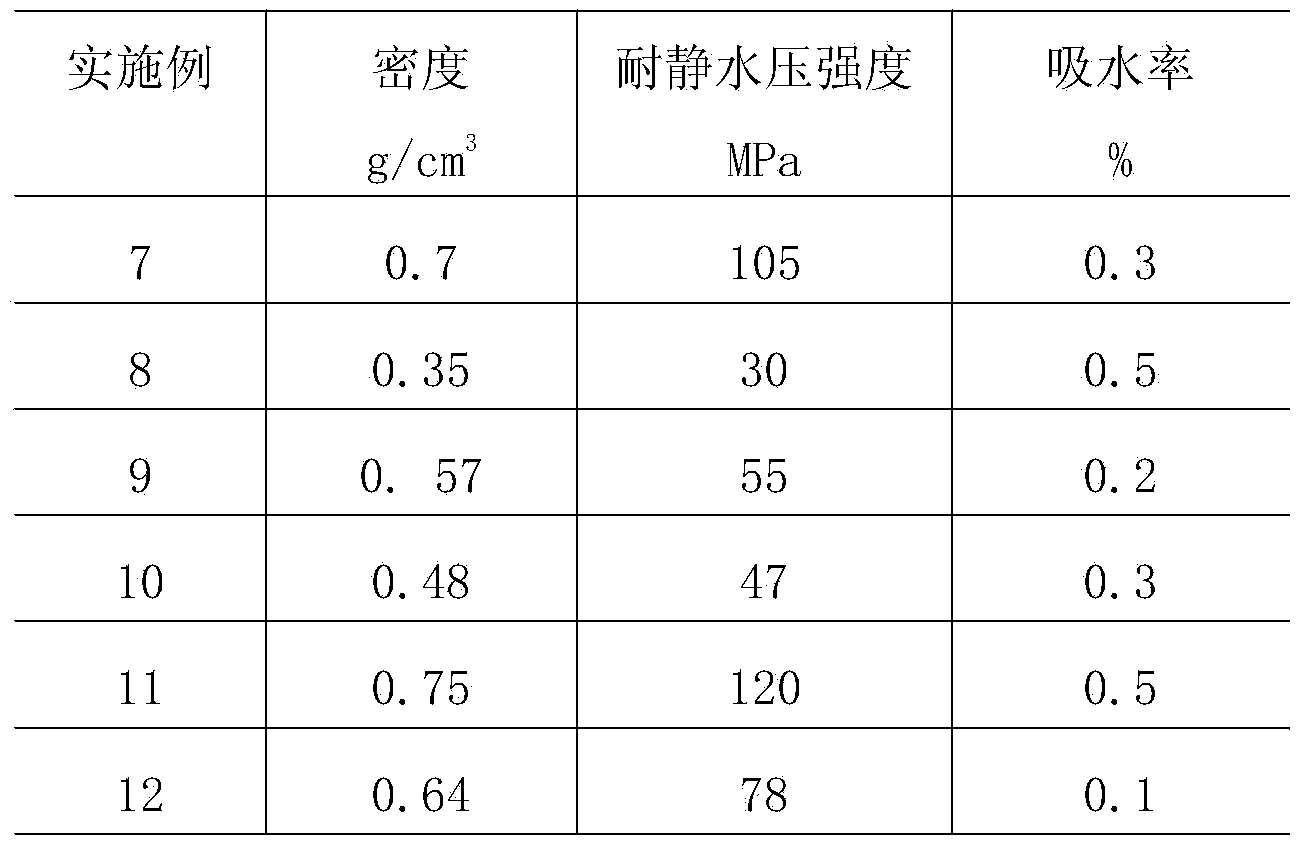

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com