Method for extracting petrologen in oil shale

A technology for extracting kerogen and oil, which is applied in the petroleum industry and the preparation of liquid hydrocarbon mixtures. It can solve the problems of cumbersome processing and long time consumption, and achieve the effect of simple process and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

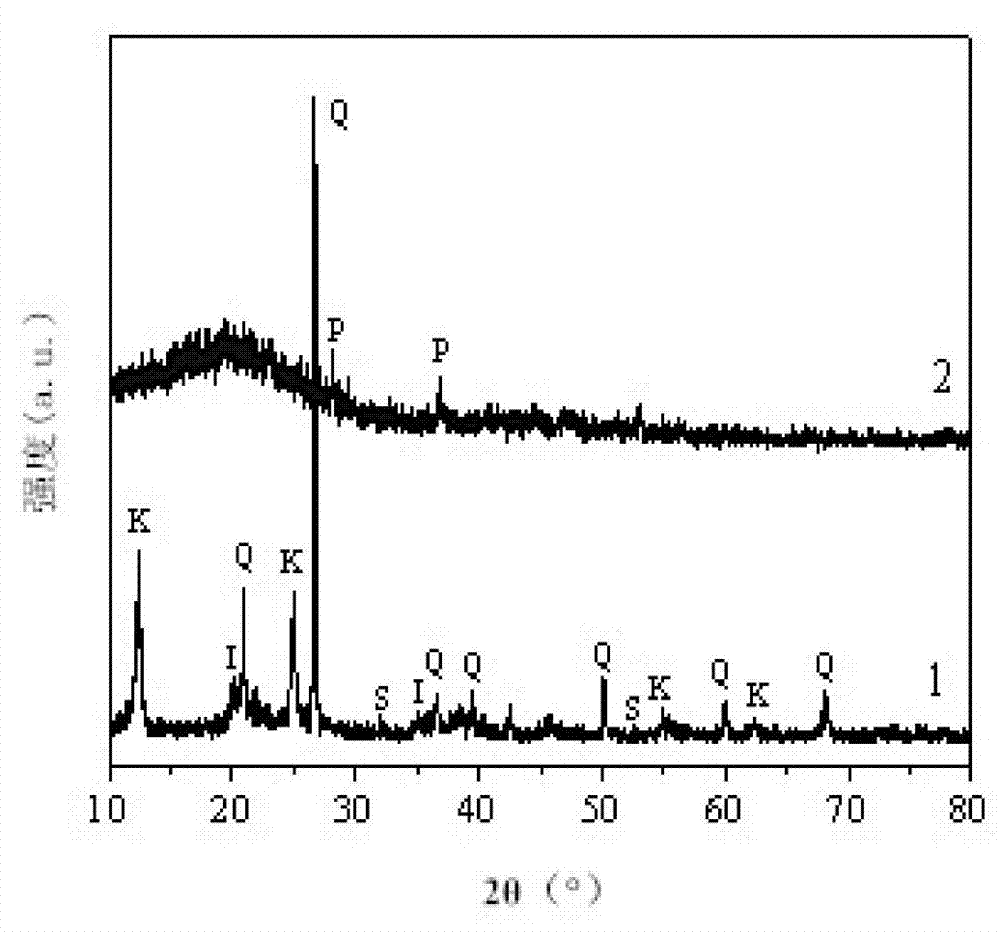

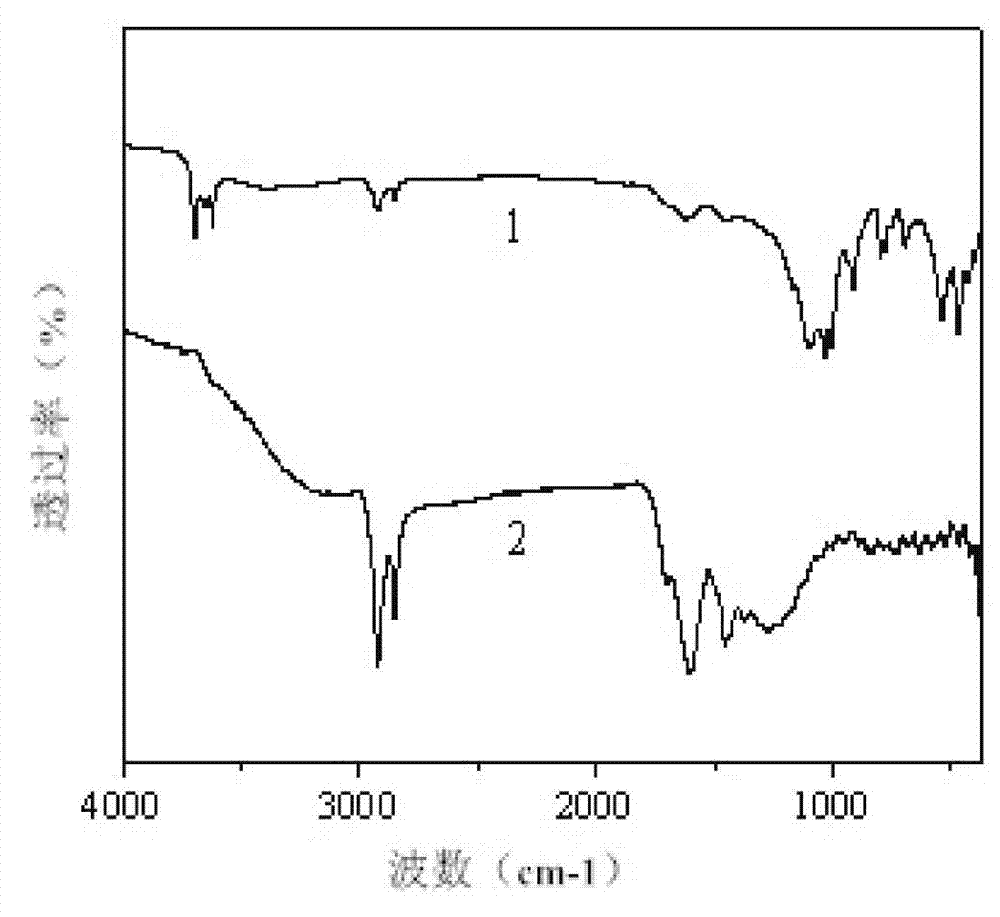

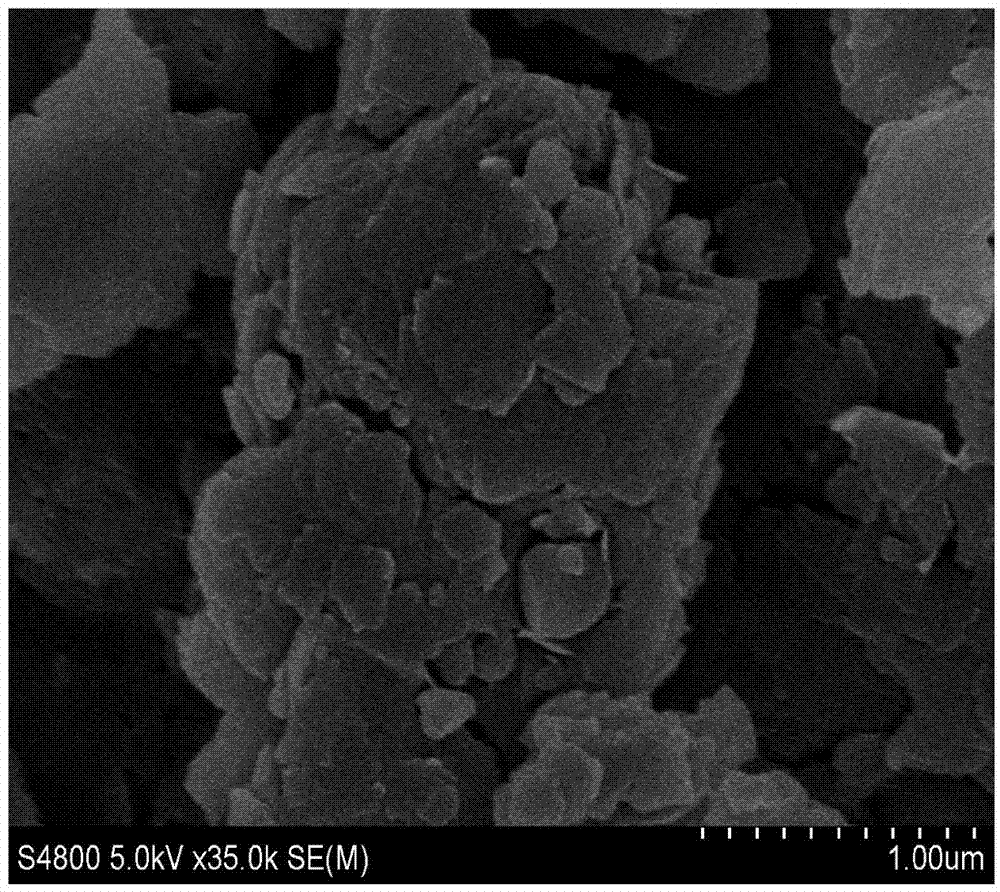

[0019] Specific embodiment one: a kind of method for extracting kerogen in oil shale in this embodiment, carries out according to the following steps:

[0020] 1. Crush oil shale into oil shale powder, and sieve to obtain oil shale particles with a mesh number of 100 mesh to 300 mesh;

[0021] 2. Put oil shale particles with a mesh number of 100 mesh to 300 mesh into a polytetrafluoroethylene tube, then add a hydrofluoric acid solution with a mass fraction of 5% to 40% into the polytetrafluoroethylene tube, and shake for 5 minutes ~20min;

[0022] 3. Put the PTFE tube shaken in step 2 into a microwave digestion apparatus, and react for 5 minutes to 80 minutes under the conditions of microwave power of 400W-1000W and microwave temperature of 40°C-140°C to obtain a brown-black solid-liquid mixture ;

[0023] Four, then carry out suction filtration to the brown-black solid-liquid mixture that step 3 obtains, then adopt deionized water to wash filter residue, wash until the loti...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 1, oil shale particles with a mesh number of 200 mesh are obtained by sieving. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that in step 2, a hydrofluoric acid solution with a mass fraction of 30% is added to the polytetrafluoroethylene tube. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com