Masking tool for evaporation of electrodes of micro-mechanical quartz sensor

A micromechanical sensor and mask technology, applied in vacuum evaporation plating, sputtering plating, ion implantation plating, etc., can solve the problems of poor surface electrode shielding protection, unsuitable for mass substrate production, large deformation, etc. , to achieve the effect of facilitating production operation, reducing alignment and fixing, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further introduced below in conjunction with the accompanying drawings.

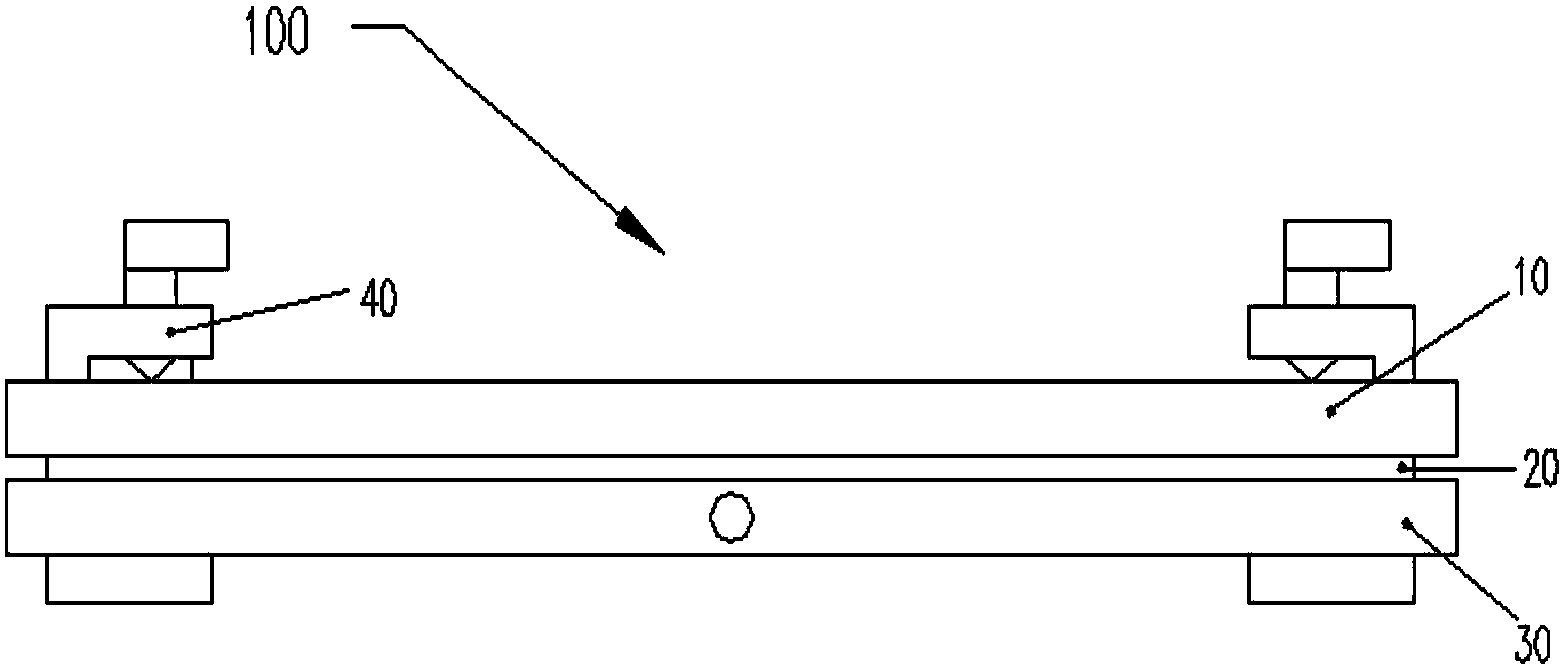

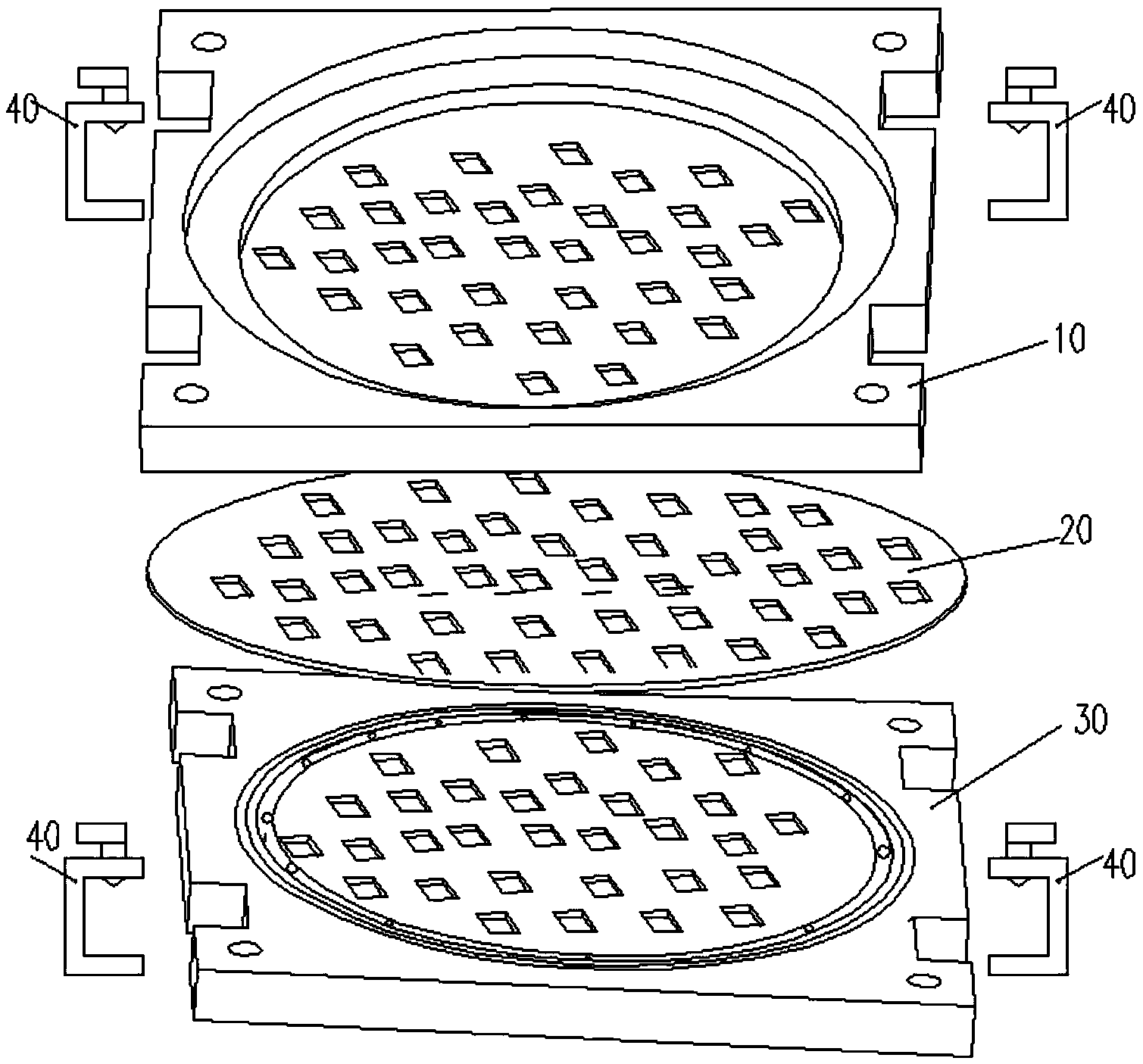

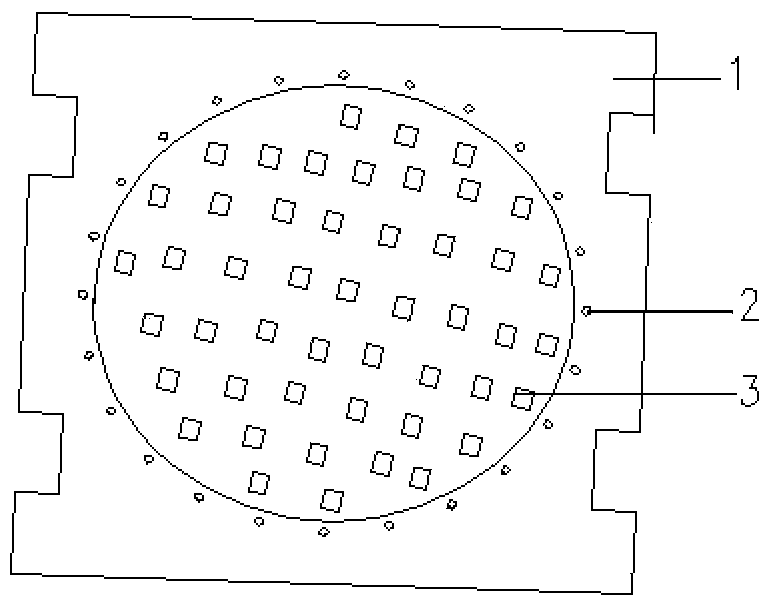

[0020] As shown in FIG. 1 , the present invention provides a mask tooling 100 for electrode evaporation of quartz micromechanical sensors. The mask tooling 100 includes an upper mask plate 10 , a lower mask plate 30 and a fixing fixture 40 . As shown in Figure 2, the upper mask 10 includes a first frame 1 and a first thin plate 3; the first thin plate 3 is fixed on the lower surface of the first frame 1 by laser welding, and the laser welding points 2 left on the surface not higher than the surface of the first thin plate 3 . A first tapered hole 11 is formed on the first frame 1, and the diameter of the upper end of the first tapered hole is larger than that of the lower end. As shown in Figure 3, the lower mask 30 includes a second frame 5 and a second thin plate 8; the second thin plate 8 is fixed on the upper surface of the second frame 5 by laser welding, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com