Flat package crimping type extraction electrode insulated gate bipolar transistor element

A bipolar transistor and lead-out electrode technology, which is applied in the field of flat-panel package crimp-type lead-out electrode insulated gate bipolar transistor components, can solve the problem of poor resistance to external impact, fire prevention, and explosion protection, and enlarge the element die and base plate Thermal resistance, poor ability to withstand current surges, etc., to eliminate current imbalance factors, reduce heat conduction resistance, and increase flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

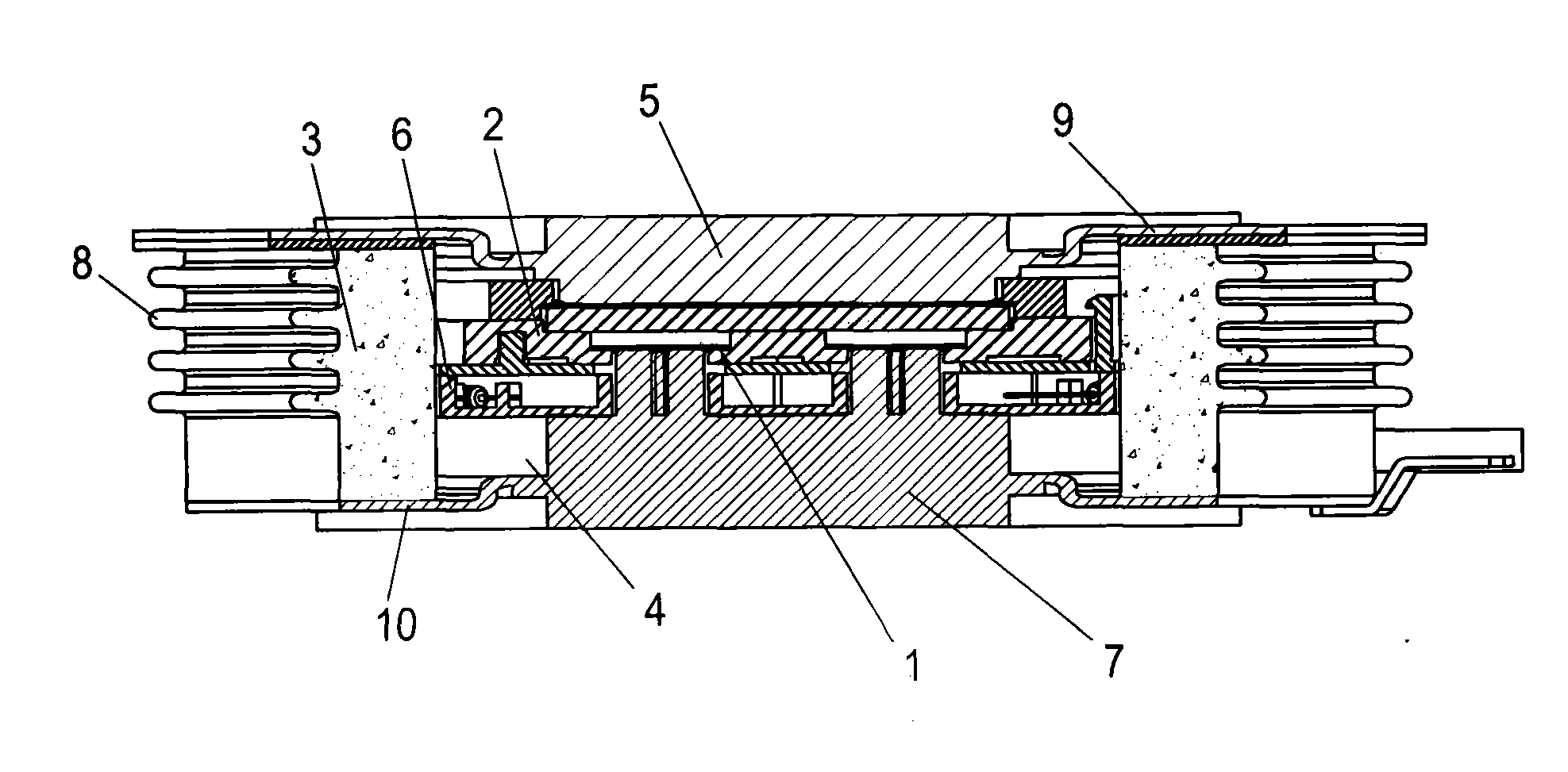

[0026] like figure 1 As shown, the flat package crimping type lead-out insulated gate bipolar transistor (IGBT) element of the present invention includes an IGBT chip 1, and also includes a chip mold frame 2 and a housing 3 made of ceramics. The upper edge of the housing 3 is vertical There is a chip mounting hole 4 in the direction, and a chip mounting sinker is provided on the chip mold frame 2. The IGBT chip 1 is fixed in the chip mounting sinker on the chip frame 2, and the chip frame 2 is fixed in the chip mounting hole 4. The upper part of the chip mold frame 2 is provided with an upper lead-out electrode plate 5 as the emitter of the IGBT. The upper lead-out electrode plate 5 is made of metal material, and the upper lead-out electrode plate 5 is installed on the upper part of the chip mounting hole 4. The upper lead-out electrode plate 5 The lower end surface of the electrode plate 5 is attached to the circuit port of the emitter on the IGBT chip 1;

[0027] A gate mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com