Thin-film lithium battery and preparation method thereof

A lithium battery and thin film technology, applied in the field of thin film lithium battery and its preparation, can solve the problems of inflexibility and inability to prepare battery thin films, and achieve the effects of reducing stress, improving reliability and good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

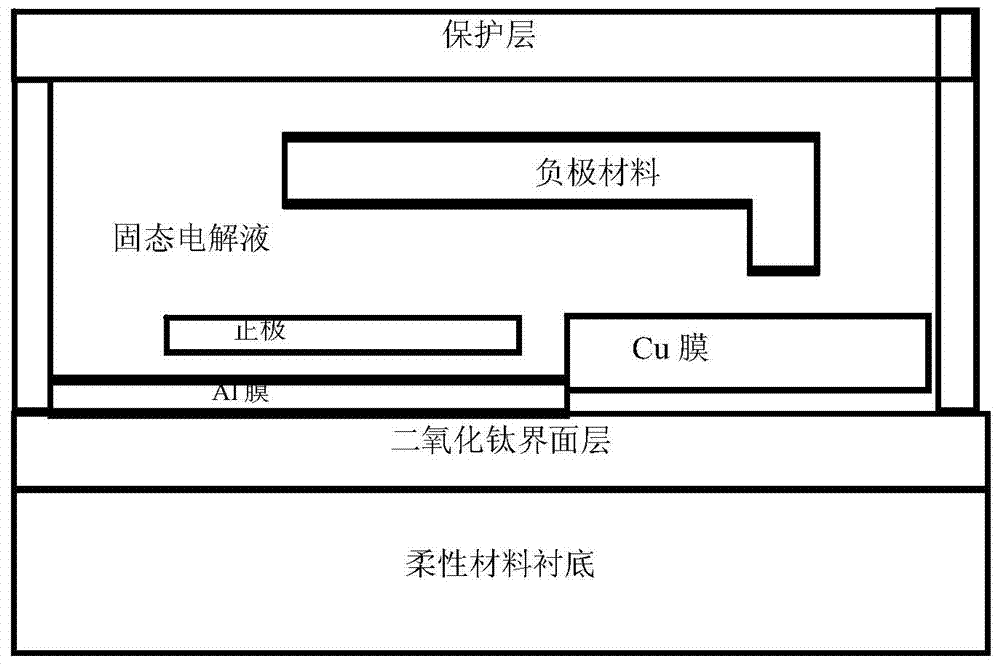

[0031] Such as figure 1 Shown is a thin-film lithium battery, including a protective case and a substrate, the protective case is provided with a positive electrode, a negative electrode and an electrolyte, and the substrate is a flexible material substrate.

[0032] The flexible material substrate is a flexible substrate made of polyethylene terephthalate.

[0033] The titanium dioxide interface layer is sputtered on the flexible material substrate, and the main purpose of sputtering the titanium dioxide is to play the role of a buffer layer, which can reduce the stress generated in the thin film battery.

[0034] The thickness range of the titanium dioxide interface layer is 200nm-500nm.

[0035] The above-mentioned preparation method of a thin film lithium battery is characterized in that the following steps are carried out in sequence:

[0036] (1) Prepare a flexible material as a substrate, and use a titanium target to coat it on the substrate of a flexible plate under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com