High-activity nut antioxidative peptide and preparation method thereof

An antioxidant peptide, high activity technology, applied in protein food processing, plant protein processing, food science, etc., can solve the problem of low activity of oxidized peptides, achieve the effect of protective activity, high antioxidant activity, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

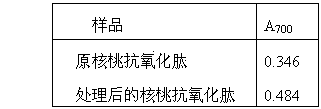

Image

Examples

Embodiment 1

[0022] (1) Prepare a solution of nut protein isolate with a concentration of 2%, process at a temperature of 90 ° C for 7 min, and cool to room temperature;

[0023] (2) Adjust the pH value of the above nut protein isolate solution to 7.0, the temperature of the water bath is 40°C, add 2.4L of Alcalase at a ratio of 1000U / g, enzymatically hydrolyze for 1h, then quickly heat up to 90°C and keep it for 15min for enzyme inactivation treatment, and cool to room temperature , adjust the pH of the hydrolyzate to 7.0;

[0024] (3) Add amylosucrase and sucrose, the mass ratio of isolated protein and sucrose is 1:1, the amount of amylosucrase added is 100U / g, and it is treated at 35°C for 1h;

[0025] (4) Cool to room temperature, centrifuge at 5000 r / min for 10 min, take the supernatant, concentrate, freeze-dry to obtain the product.

Embodiment 2

[0027] (1) Prepare a nut protein isolate solution with a concentration of 6%, process at a temperature of 90 ° C for 13 min, and cool to room temperature;

[0028] (2) Adjust the pH value of the above nut protein isolate solution to 8.5, the temperature of the water bath is 50°C, add 2.4L of Alcalase at a ratio of 5000U / g, enzymatically hydrolyze for 3.5h, then quickly heat up to 90°C and keep it for 15min to inactivate the enzyme, and cool to At room temperature, adjust the pH of the hydrolyzate to 7.0;

[0029] (3) Add amylosucrase and sucrose, the mass ratio of protein isolate to sucrose is 1:3, the amount of amylosucrase added is 200U / g, and it is treated at 35°C for 5.5h;

[0030] (4) Cool to room temperature, centrifuge at 5000 r / min for 10 min, take the supernatant, concentrate, freeze-dry to obtain the product.

Embodiment 3

[0032] (1) Prepare a nut protein isolate solution with a concentration of 10%, process at a temperature of 90 ° C for 20 min, and cool to room temperature;

[0033] (2) Adjust the pH value of the above nut protein isolate solution to 10, the temperature of the water bath is 60°C, add 2.4L of Alcalase at a ratio of 9000U / g, enzymatically hydrolyze for 6h, then quickly heat up to 90°C and keep it for 15min to inactivate the enzyme, then cool to room temperature , adjust the pH of the hydrolyzate to 7.0;

[0034] (3) Add amylosucrase and sucrose, the mass ratio of protein isolate to sucrose is 1:5, the amount of amylosucrase added is 300U / g, and it is treated at 35°C for 10h;

[0035] (4) Cool to room temperature, centrifuge at 5000 r / min for 10 min, take the supernatant, concentrate, freeze-dry to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com