Coarse coal slime sorting machine

A technology of sorting machine and coarse coal slime, which is applied in the field of coal mine machinery and equipment, can solve the problems of low solid content, unsatisfactory sorting effect, and affecting the sorting effect, so as to reduce production costs and process costs and improve the sorting effect. Significant, high-efficiency sorting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

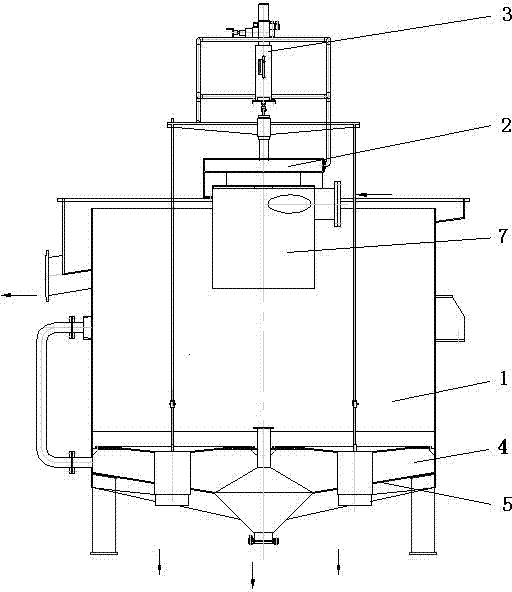

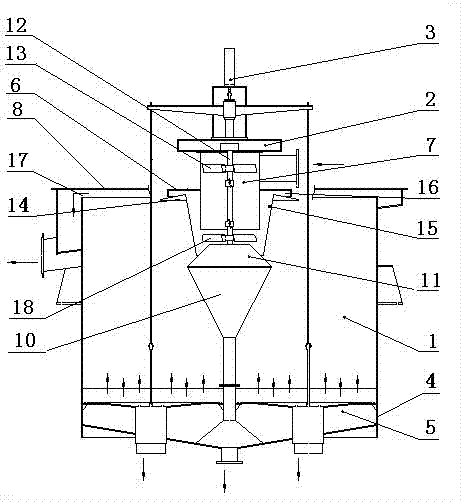

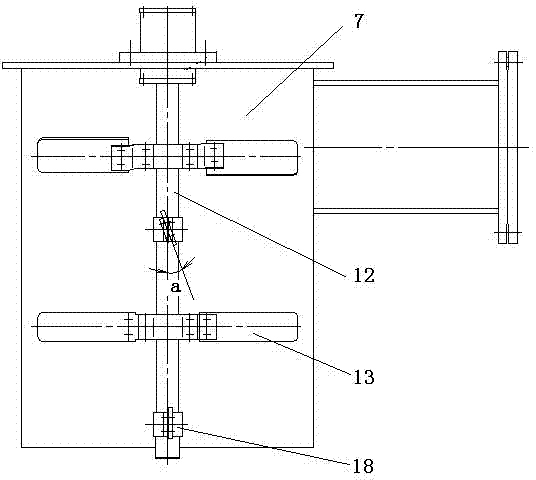

[0022]As shown in the attached figure, a sorting machine for coarse coal slime includes a host cylinder 1, a platform 2, an electric actuator 3, a water tank 4, a water tank injection device 5, a feeding cylinder 7, a top cover 8 and a lower cone 10. The lower vertebral body is fixedly connected to the bottom of the main engine cylinder through the bracket, the main engine cylinder 1, the platform 2, the electric actuator 3, the water tank 4, the water tank injection device 5, the feeding cylinder 7, the top cover 8 and the lower vertebral body The structure and connection relationship of the body 10 are the same as those of the prior art, so I won’t go into details here. It is characterized in that the upper end of the lower vertebral body 10 is provided with a conical diffusion platform 11, and the large-diameter end of the conical diffusion platform 11 is fixedly connected with the lower vertebral body 10. , the small-diameter end corresponds to the outlet of the feeding cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com