Composite pre-laid waterproof coiled material

A waterproof membrane and composite technology, which is applied in adhesive types, synthetic resin layered products, mineral oil hydrocarbon copolymer adhesives, etc., and can solve the problems of inability to tear off, aging of the adhesive layer, and difficulty in tearing off, etc. problem, to achieve the effect of preventing direct sunlight on the adhesive layer, high bonding strength, and preventing sticking feet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: A composite pre-paved waterproof coiled material, comprising a modified asphalt polyester tire coiled material substrate and an adhesive layer and a protective layer arranged on the modified asphalt polyester tire coiled material substrate, the adhesive layer will The protective layer is bonded on the modified asphalt polyester tire coil base, and the protective layer is granular sand grains or rubber grains. The adhesive layer is a hot-melt pressure-sensitive adhesive, and the adhesive layer bonds the protective layer and the modified asphalt polyester tire coil base into one body. The particles of the protective layer have a particle diameter of 0.5 mm.

[0036] The adhesive layer in this embodiment is a hot-melt pressure-sensitive adhesive, and the preparation method of the hot-melt pressure-sensitive adhesive is as follows: mix the mixture of SBS and SIS, and the plasticizer in a three-necked flask in proportion, soak and fill with oil, and then Add ta...

Embodiment 2

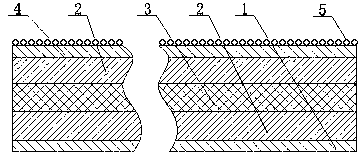

[0037] Example 2: Please refer to the attached figure 1 , a composite pre-paved waterproof membrane, comprising a modified asphalt polyester tire membrane substrate and an adhesive layer 4, a protective layer 5, and an adhesive layer 4 arranged on the modified asphalt polyester tire membrane substrate The protective layer 5 is bonded on the base of the modified asphalt polyester tire coil; Modified asphalt layer 2 composition on both sides. In this embodiment, the carcass 3 is a long-fiber polyester tire made of long-fiber polyester material. In this embodiment, the thickness of the adhesive layer 4 is 0.2mm. In this embodiment, the modified asphalt layer is made of SBS modified asphalt material. In this embodiment, the bottom layer 1 is a high-density polyethylene film. The protective layer is composed of colloidal particles with a particle diameter of 0.50 mm. In this embodiment, the overall thickness of the composite pre-paved waterproof roll is 4mm.

[0038] The ad...

Embodiment 3

[0039] Example 3: The difference between this embodiment and embodiment 2 is that in this embodiment, the carcass 3 in this embodiment is made of a high-strength 7000F resin film. In this embodiment, the thickness of the adhesive layer 4 is 0.25 mm. The grain size of the sand grains of the protective layer is 0.3mm.

[0040] The adhesive layer in this embodiment is a hot-melt pressure-sensitive adhesive, and its components include: 98 parts of a mixture of SBS and SIS, including 50 parts of SBS and 48 parts of SIS; 4 parts of plasticizer; 3 parts of filler; naphthene 32 parts of oil; 1.2 parts of anti-aging agent; 110 parts of tackifying resin. Refer to Example 1 for the preparation method of the hot-melt pressure-sensitive adhesive.

[0041] The adhesive layer in this embodiment is a hot-melt pressure-sensitive adhesive, and the preparation method of the hot-melt pressure-sensitive adhesive is as follows: mix the mixture of SBS and SIS and the plasticizer in a three-necke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com