Resin composition for optical film containing trapezoidal silsesquioxane polymer

A resin composition, silsesquioxane technology, applied in optics, optical components, instruments, etc., to achieve the effects of excellent light transmittance, improved physical properties, and excellent plasticizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

[0058] Synthesis Example 1: Preparation of cellulose solution

[0059] After 1 part by weight of triacetyl cellulose (Sigma-Aldrich, Fluka) was dropped into 9 parts by weight of mixed solvent in which dichloromethane and methanol were mixed at 9:1 (weight ratio), and mixed for more than 1 day , A cellulose solution was prepared.

Synthetic example 2

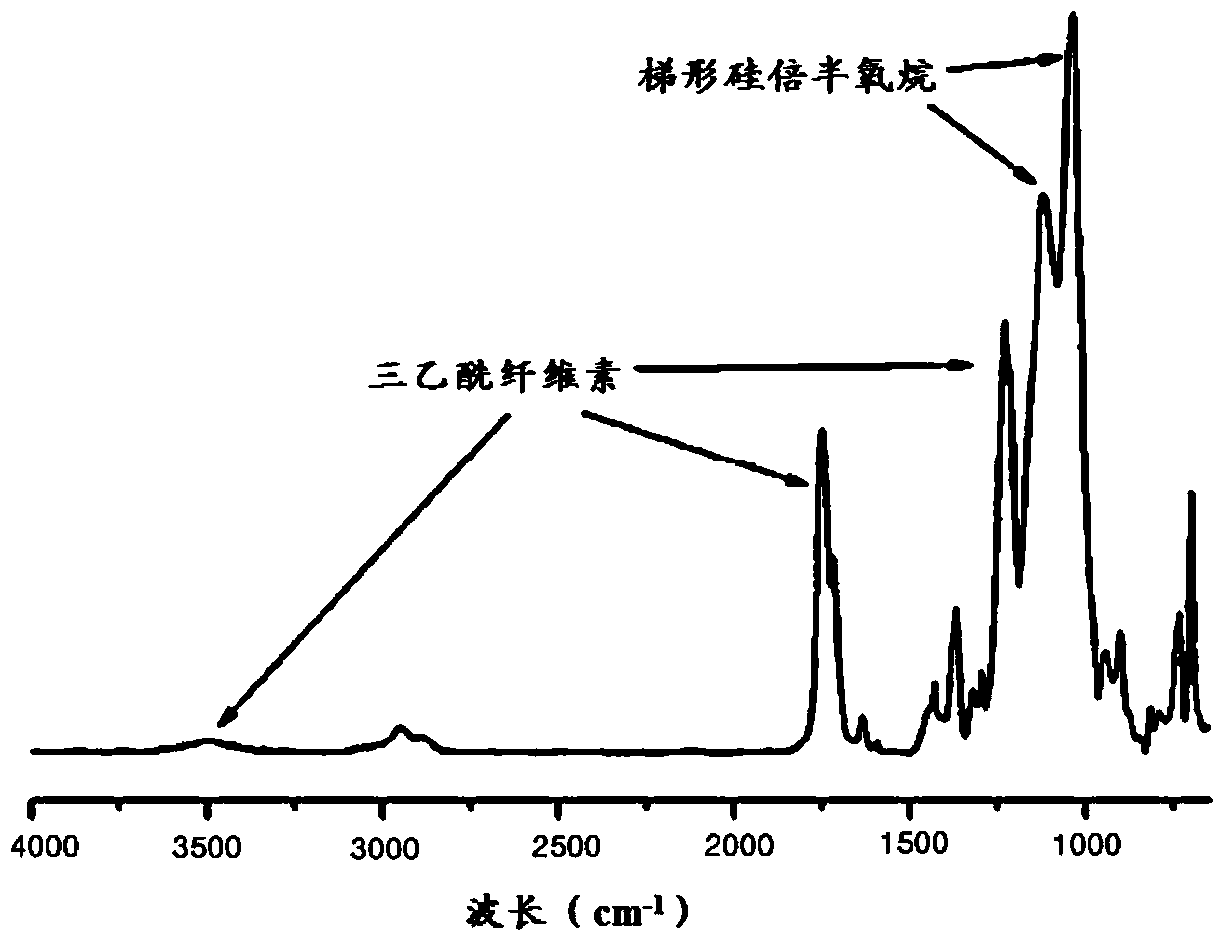

[0060] Synthesis Example 2: Preparation of Silsesquioxane Polymer

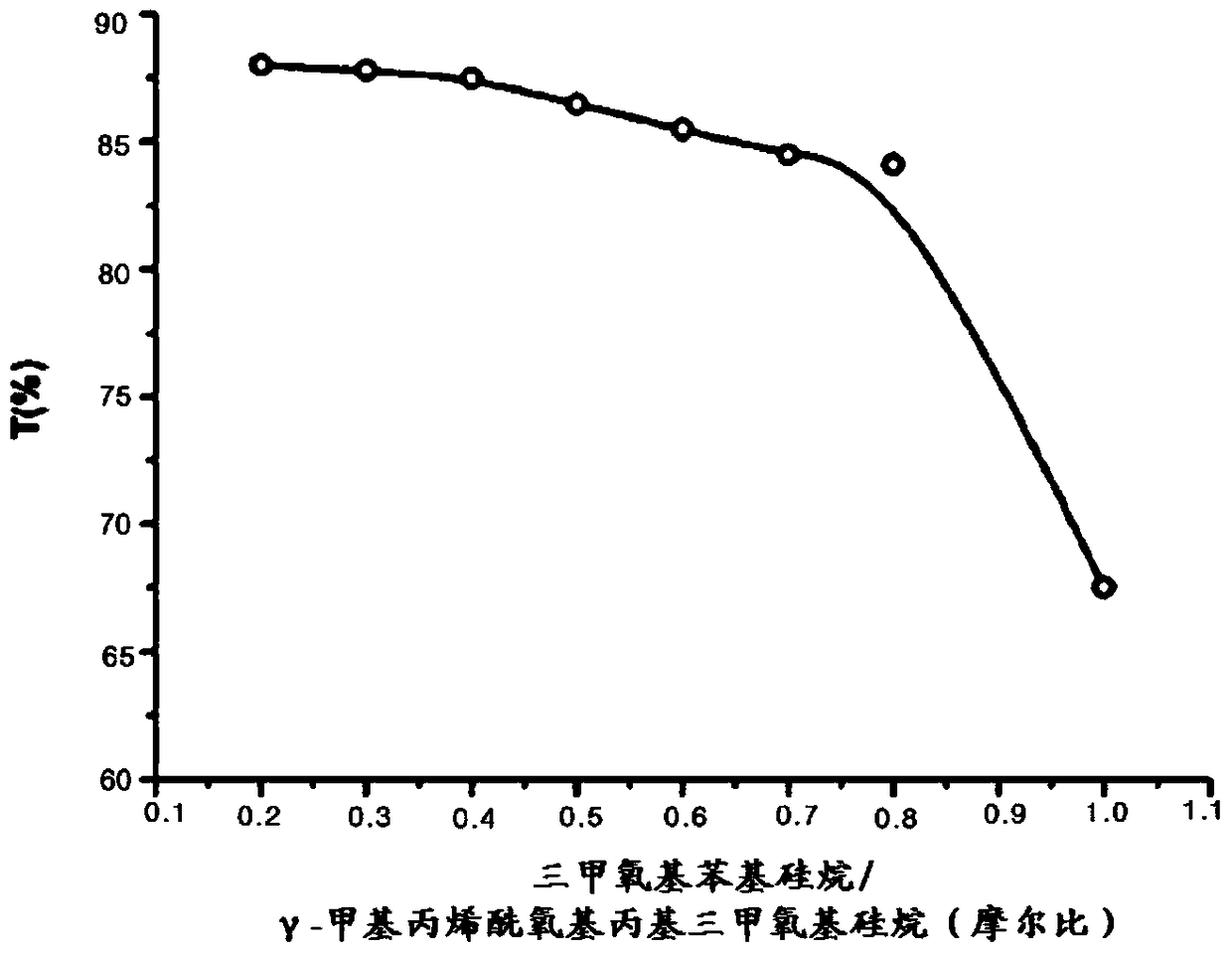

[0061] In a dry flask equipped with a cooling tube and a stirrer, 15% by weight of distilled water, 4% by weight of methanol (purity 99.86%), and 1% by weight of tetramethylammonium hydroxide (25% aqueous solution (in water)) were mixed beforehand. After preparing the mixed reaction solvent containing the catalyst, 80% by weight of the silane monomer was added to the prepared mixed reaction solvent. At this time, the mixing ratio of the added silane monomers is trimethoxyphenylsilane (Dow Corning, trade name DOWCORNING(R)Z-6124SILANE) 10 mol%: γ-methacryloxypropyl trimethoxy Silane (Dow Corning, trade name DOWCORNING (R) Z-6030SILANE) 90 mol%.

[0062] Thereafter, after slowly stirring for 8 hours in a nitrogen atmosphere, the stirring of the reaction solution was stopped, and after being left at room temperature for 24 hours, the reaction solution containing the precipitate was subjected to vacuum filtration to s...

Embodiment 1 to 5

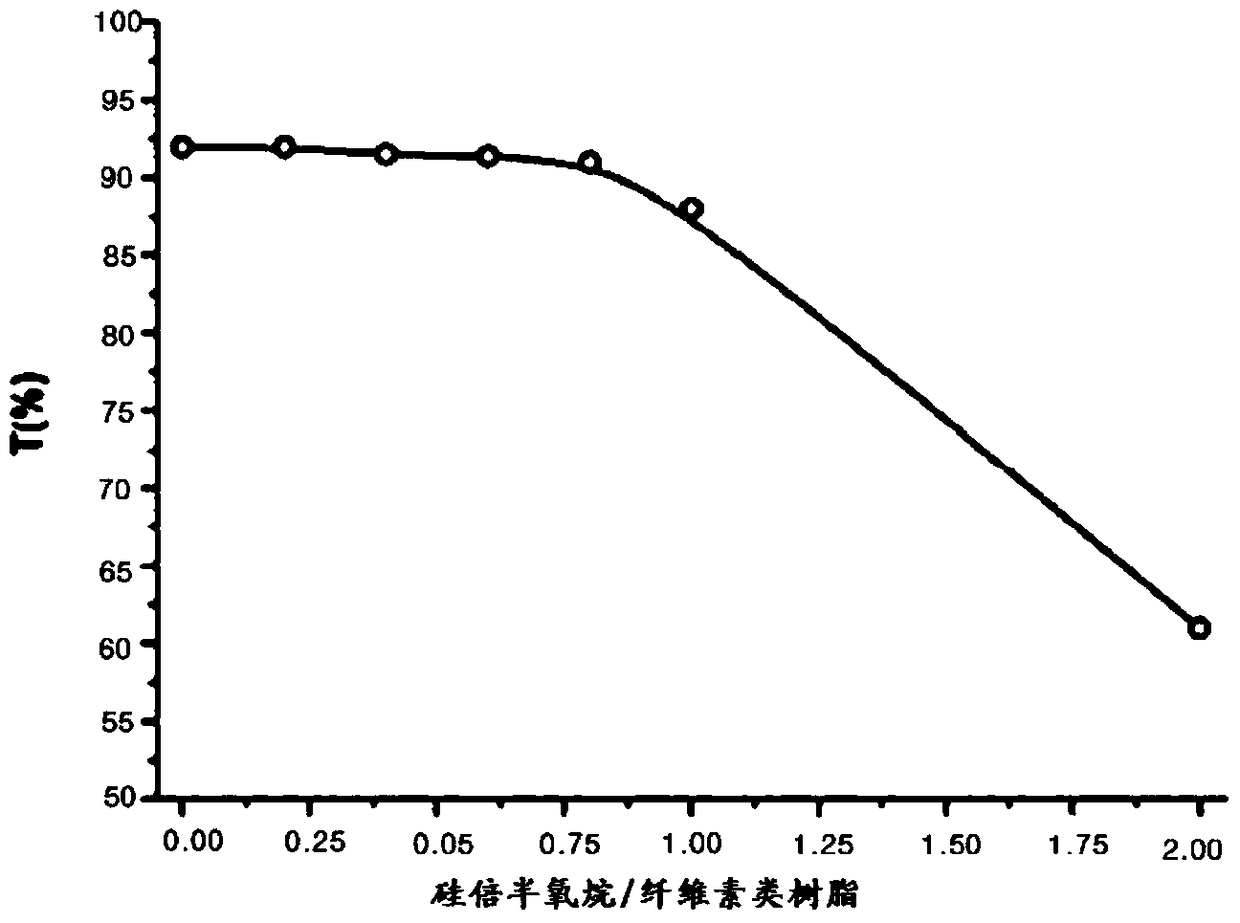

[0067] Examples 1 to 5: Preparation of mixed solution of cellulose / silsesquioxane resin composition, and film production using solution casting method

[0068] 1 part by weight of the cellulose solution prepared in the above synthesis example 1 was mixed with 0.2, 0.4, 0.6, 0.8, and 1 part by weight, respectively, of the silsesquioxane polymer prepared in the above synthesis example 2 to prepare Resin composition prepared by solution casting. The prepared composition was cast on a glass plate at a speed of 20 cm / sec and dried with hot air to prepare a film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com