Method for synchronously removing carbon, nitrogen and sulfur in wastewater

A technology for carbon nitrogen and waste water, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of complex process, inability to be widely used, huge engineering investment, etc., and achieve simple process , reduced operating costs, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

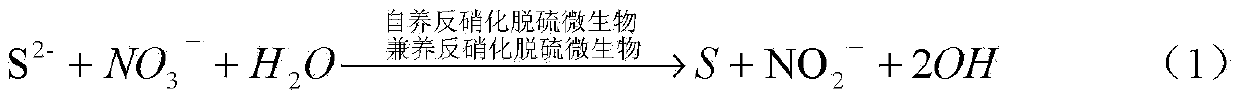

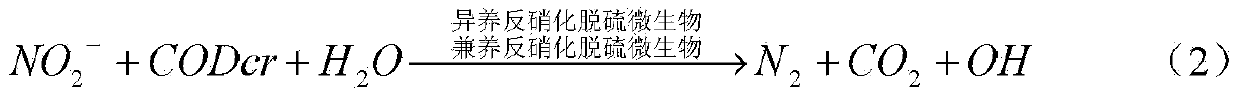

Method used

Image

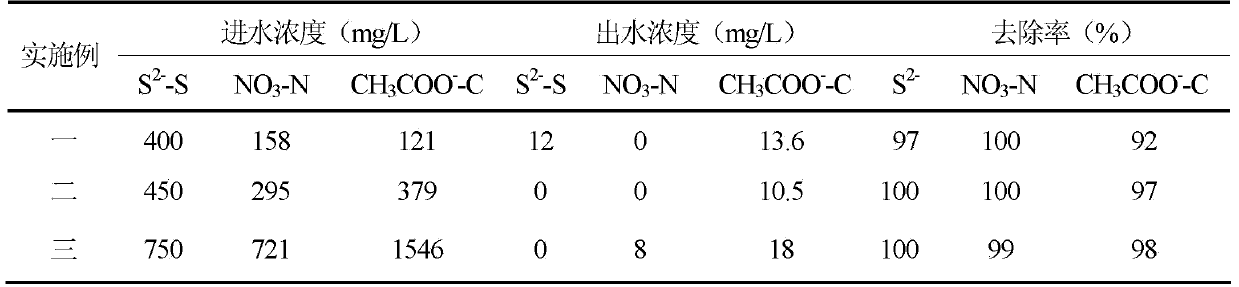

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: the method for synchronous removal of carbon, nitrogen and sulfur in the waste water of this embodiment is carried out according to the following steps:

[0019] 1. Acclimatization of microbial sludge rich in concurrent denitrification and desulfurization: in an anaerobic reactor, activated sludge is used as inoculation sludge, and a mixture of sulfide and nitrate and a mixture of organic matter and nitrate are used as substrates respectively. Alternately domesticate the sludge under autotrophic and heterotrophic conditions. When the removal rate of sulfide and nitrate is ≥85% under autotrophic condition, and the removal rate of organic matter and nitrate is ≥85% under heterotrophic condition, domestication is completed;

[0020] 2. In the anaerobic reactor that is rich in concurrent denitrification and desulfurization microbial sludge domesticated in step one, feed the waste liquid to be treated, and adjust and control the mol ratio of nitrogen ...

specific Embodiment approach 2

[0027] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the activated sludge in step 1 comes from the secondary settling tank of the municipal sewage plant. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the removal rate of sulfide and nitrate under the autotrophic condition described in step one is 95%, and the removal rate of organic matter and nitric acid is 95% under the heterotrophic condition When the removal rate of salt is 95%, acclimatization is completed. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com