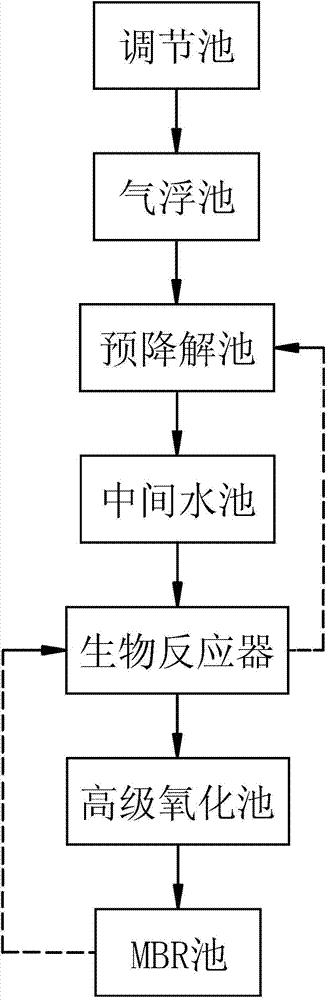

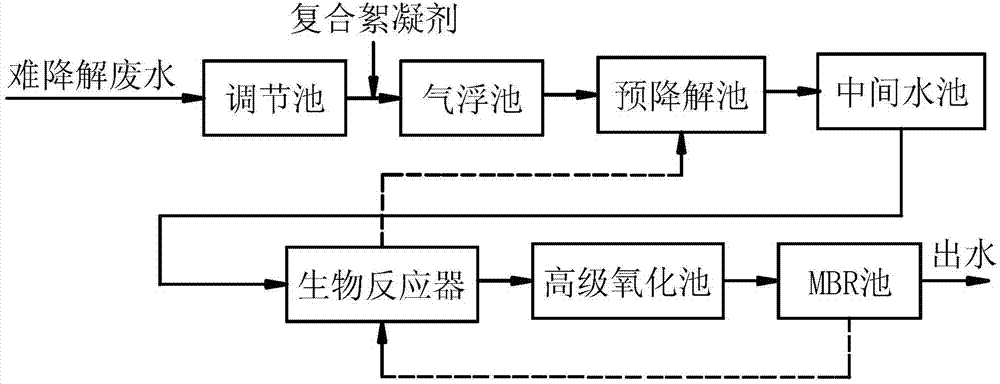

Method and device for efficient biochemical treatment of refractory wastewater

A biochemical treatment device and refractory technology, applied in the field of water treatment, can solve problems such as poor effect, difficult treatment, and substandard discharge, and achieve the effects of wide application range, good treatment effect and short residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A papermaking wastewater, raw water COD Cr 1000mg / L~1500mg / L, BOD 5 It is 100mg / L~200mg / L. It is oxidized by the micro-electrolytic oxidation tank first, and then biochemically treated by the bioreactor. After being treated by the Fenton oxidation tank, the wastewater COD Cr Reduced to 300mg / L~600mg / L, BOD 5 reduced to 100mg / L~150mg / L; after being treated by MBR pool, the wastewater COD Cr Reduced to 50mg / L~80mg / L, reaching the emission standard.

[0062] The membrane module set in the MBR pool is an anti-fouling flat membrane module, and the membrane flux is 10L / m 2 h; Micro-electrolytic oxidation pool can be replaced by one or more of anaerobic acidification pool or hydrolytic acidification pool; Fenton oxidation pool can be replaced by ozone oxidation pool, chemical oxidation pool, electro-oxidation pool or photocatalytic oxidation pool one or more of .

Embodiment 2

[0064] A printing and dyeing wastewater, raw water COD Cr 5000mg / L~7000mg / L, BOD 5 300mg / L~500mg / L; first undergo oxidation treatment in anaerobic acidification tank, then biochemical treatment in bioreactor; then after treatment in ozone oxidation tank, the wastewater COD Cr Reduced to 400mg / L~600mg / L, BOD 5 reduced to 100mg / L~200mg / L; after being treated by the MBR pool, the wastewater COD Cr Reduced to 70mg / L ~ 80mg / L, reaching the emission standard.

[0065] The membrane module set in the MBR pool is an anti-fouling flat membrane module, and the membrane flux is 30L / m 2 h; the anaerobic oxidation pool can be replaced by one or more of micro-electrolytic oxidation pools or hydrolytic acidification pools; the ozone oxidation pool can be replaced by chemical oxidation pools, Fenton oxidation pools, electro-oxidation pools or photocatalytic oxidation pools one or more of .

Embodiment 3

[0067] A coking wastewater, raw water COD Cr 5000mg / L~7000mg / L, BOD 5 300mg / L~500mg / L; first undergo oxidation treatment in anaerobic acidification tank, then biochemical treatment in bioreactor; then after treatment in ozone oxidation tank, the wastewater COD Cr Reduced to 400mg / L~600mg / L, BOD 5 reduced to 100mg / L~200mg / L; after being treated by the MBR pool, the wastewater COD Cr Reduced to 60mg / L~70mg / L, reaching the emission standard.

[0068] The membrane module set in the MBR pool is an anti-pollution flat membrane module, and the membrane flux is 15L / m 2 h; the anaerobic oxidation pool can be replaced by one or more of micro-electrolytic oxidation pools or hydrolytic acidification pools; the ozone oxidation pool can be replaced by chemical oxidation pools, Fenton oxidation pools, electro-oxidation pools or photocatalytic oxidation pools one or more of .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com