PVC black master batch

A technology of black masterbatch and mass parts, which is applied in the field of polymer material functional masterbatch and PVC black masterbatch, and can solve problems such as poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below.

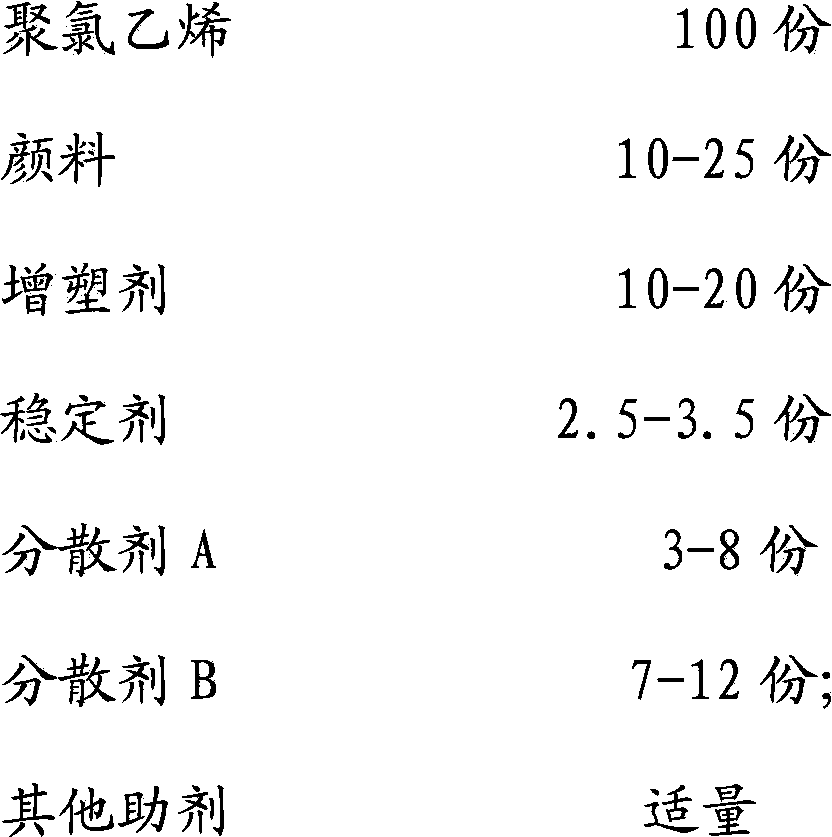

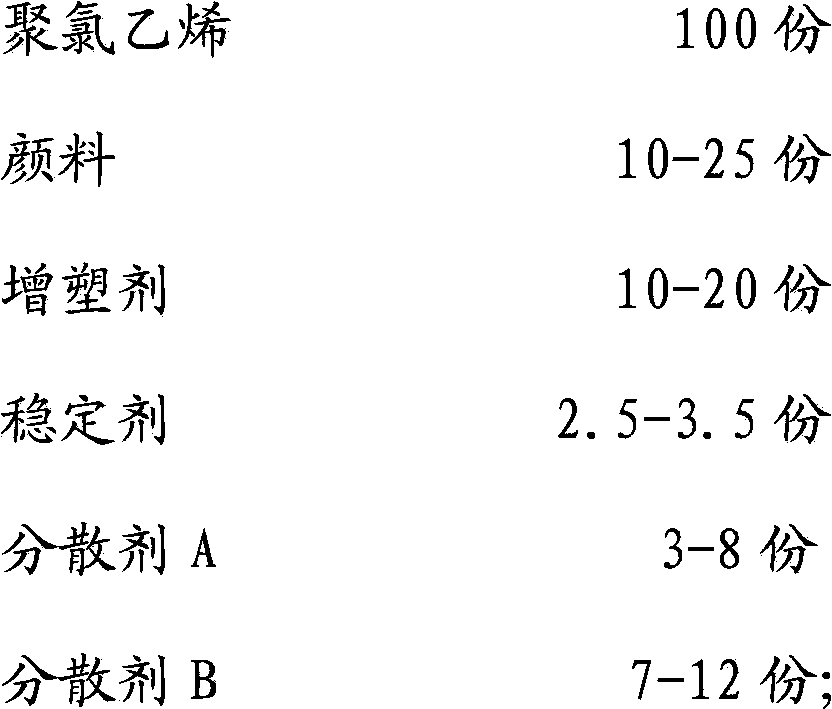

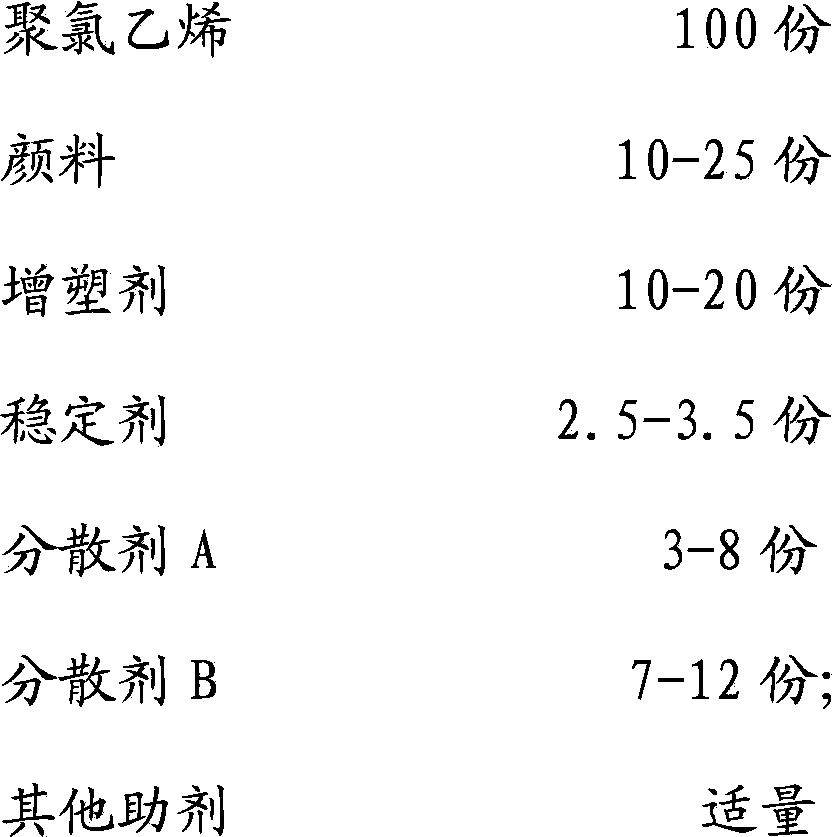

[0012] PVC black masterbatch of the present invention is used for PVC cable material, and its composition by mass parts is:

[0013]

[0014] The plasticizer is a mixture of pentaerythritol esters and trioctyl trimellitate;

[0015] Described stabilizer is zinc stearate;

[0016] Dispersant A is white oil;

[0017] Dispersant B is a mixture of polyethylene wax homopolymer and ethylene-vinyl acetate copolymer wax.

[0018] The process flow is as follows: Dispersant A, pigment black, carbon black, and plasticizer are first ground; then mixed with stabilizer, dispersant B, carrier polyvinyl chloride and other additives, and stirred in a high-speed kneader; finally Extruder granulation.

[0019] The addition amount of the masterbatch in PVC resin is 3-5 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com