Novel beta-lactam antibiotic synthetase production method

A technology for lactams and production methods, applied in the field of production of novel β-lactam antibiotics synthetases, can solve the problems of low activity, unsuitable for industrial production, weak synthetic activity, etc., and achieve high enzyme activity and good industrial application The effect of stabilizing the value and substrate conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: Gene Design and Gene Synthesis

[0043] (1) Genetic design:

[0044] (1.1) According to the amino acid sequence of penicillin acylase of Achromobacter sp. Amino acid was replaced by arginine, and the 770th leucine was replaced by phenylalanine. These sites were introduced into mutation sites to obtain the amino acid sequence shown in SEQ ID NO: 2, and then use the online design tool Jcat (http: / / www.jcat.de / ) reverse design the nucleotide sequence after introducing the mutation site;

[0045] (1.2) According to the preferred codons required for host Escherichia coli gene expression and the G+C base content required for high-efficiency gene expression, optimize the above reverse-designed nucleotide sequence. The optimized nucleotide sequence is shown as SEQ ID NO : 3, compared with the nucleotide sequence of Achromobacter genus CCM4824 penicillin acylase (as shown in SEQ ID NO: 4): ① The rare codons of Escherichia coli are reduced from 55 to 2; ② G+C base ...

Embodiment 2

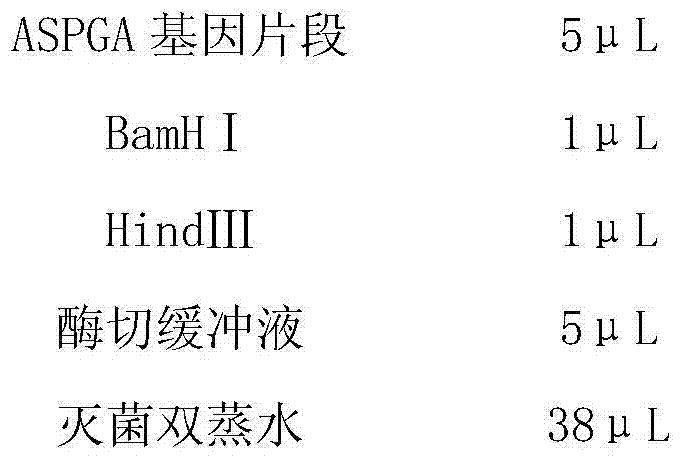

[0047] Example 2: Construction of expression vector PET28-ASPGA (i.e. recombinant vector)

[0048] (1) The ASPGA gene obtained in Example 1 was double digested with BamHI and HindIII, and the enzyme digestion system was as follows:

[0049]

[0050] The concentration of the ASPGA gene is 2 μg / 5 μL;

[0051] The above enzyme digestion system was incubated at 37°C for 4 hours, and then purified using a DNA gel recovery kit (Sangon Bioengineering (Shanghai) Co., Ltd.) to obtain the target ASPGA gene fragment.

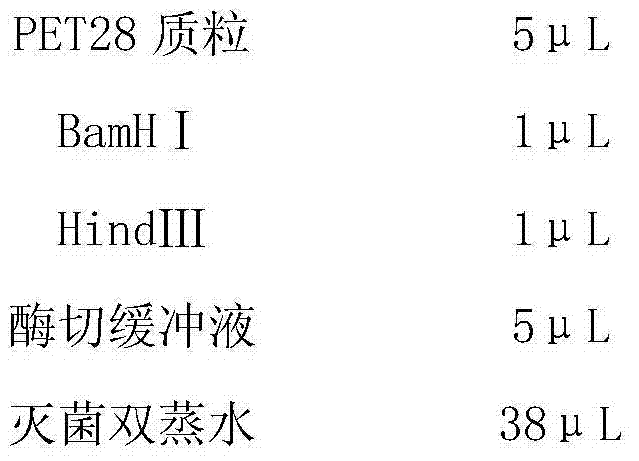

[0052] (2) Use BamHI and HindIII double enzymes to digest the PET28 plasmid (Novagen company), and the enzyme digestion system is as follows:

[0053]

[0054] The concentration of the PET28 plasmid is 2 μg / 5 μL;

[0055] The above enzyme digestion system was incubated at 37°C for 4 hours, and then purified using a DNA gel recovery kit (Sangon Bioengineering (Shanghai) Co., Ltd.) to obtain the target PET28 plasmid fragment.

[0056] (3) Use T4 ligase to ligate the...

Embodiment 3

[0063] Embodiment 3: Construction of transformant BL21(DE3) / PET28-ASPGA (i.e. recombinant strain)

[0064] (1) Pick a single colony of Escherichia coli BL21 (DE3) and inoculate it into an LB test tube. After shaking and culturing at 37°C for 8-10 hours, take 0.5ml of the culture solution and add it to a Erlenmeyer flask containing 50ml of LB, and culture it at 37°C for about 2 hours with vigorous shaking. Bacteria were grown to pre-logarithmic phase.

[0065] (2) Transfer the E. coli culture solution in the early logarithmic phase of growth to an ice-precooled polypropylene tube (capacity 50ml), place it on ice for 10 minutes, centrifuge at 4°C and 4000rpm at low temperature, and discard the supernatant. Add 6ml of ice-cooled CaCl 2 Solution (concentration 0.1mol / L) to resuspend the bacterial pellet, then place it on ice for 30min, centrifuge again at 4°C and 4000rpm at low temperature, then discard the supernatant, add 1.2ml ice-cooled CaCl 2 solution (concentration 0.1mol / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com