Method for increasing pulullan yield

A pullulan polysaccharide and yield technology is applied in the stepwise addition of growth factors to increase the yield of pullulan polysaccharide and the field of pullulan polysaccharide production, which can solve the disadvantages of large-scale, large-scale production, high cost of pullulan polysaccharide, high cost of pullulan polysaccharide, Problems such as low substrate utilization, to achieve the effect of shortening the fermentation cycle, convenient operation, and improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

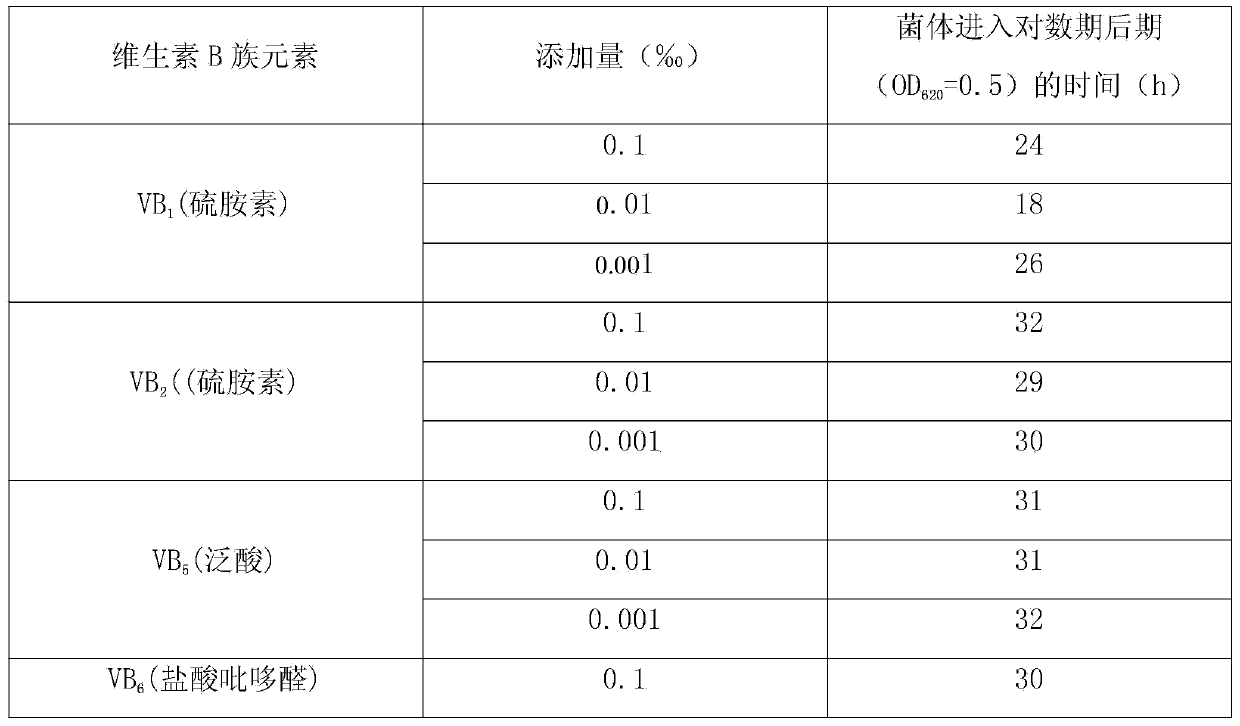

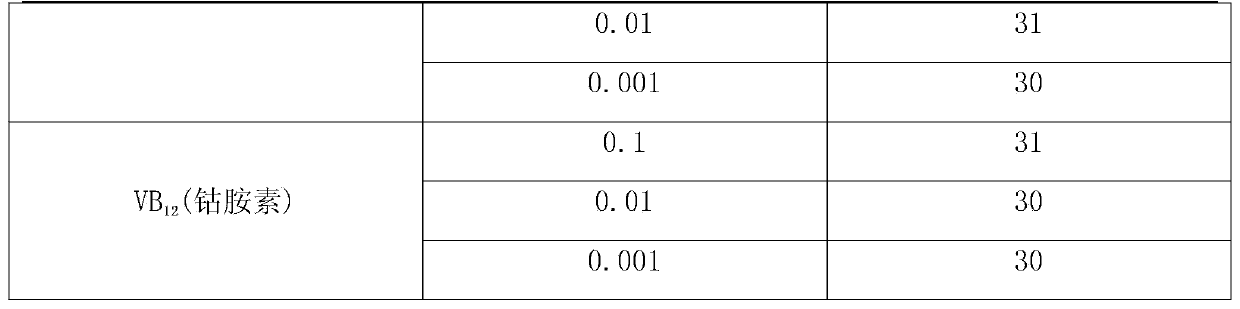

Method used

Image

Examples

Embodiment 1

[0046] (1) Seed cultivation

[0047] After activating the strain of Aureobasidium pullulans, pick one ring and transfer it to a 500ml baffle bottle, the volume of the culture medium is 100ml, the culture temperature is 32°C, the rotation speed of the shaker is 180rpm, and the culture time is 28h.

[0048] (2) Fermentation culture

[0049] The 500mL baffle bottle has a liquid volume of 100mL, an inoculum size of 4% (V / V), a temperature of 28°C, and a shaker speed of 400rpm for cultivation. When the growth of the bacteria is in the early logarithmic phase, add 0.03‰ vitamin B 1 , when the growth of the bacteria was in the early stage of the stationary phase, 0.04‰ of uracil nucleotides was added to accumulate the secondary metabolite, that is, pullulan.

[0050] (3) Separation of pullulan

[0051] After filtering out the bacterial cells in the fermentation broth, add three times of ethanol, stir, stand overnight at 4°C, centrifuge, rinse twice with absolute ethanol, and dry t...

Embodiment 2

[0054] (1) Seed cultivation

[0055] After activating the strain of Aureobasidium pullulans, pick one ring and transfer it to a 500ml baffle bottle, the volume of the culture medium is 100ml, the culture temperature is 32°C, the rotation speed of the shaker is 180rpm, and the culture time is 30h.

[0056] (2) Fermentation culture

[0057] The 500mL baffle bottle has a liquid volume of 100mL, an inoculum size of 4% (V / V), a temperature of 28°C, and a shaker speed of 400rpm for cultivation. When the growth of the bacteria is in the early logarithmic phase, add 0.04‰ vitamin B 1 , when the growth of the bacteria was in the early stage of the stationary phase, 0.03‰ of uracil nucleotides was added to accumulate the secondary metabolite, pullulan.

[0058] (3) Separation of pullulan

[0059] After filtering out the bacterial cells in the fermentation broth, add three times of ethanol, stir, stand overnight at 4°C, centrifuge, rinse twice with absolute ethanol, and dry to obtain ...

Embodiment 3

[0062] (1) Seed cultivation

[0063] After activating the strain of Aureobasidium pullulans, pick one ring and transfer it to a 500ml baffle bottle with a medium volume of 100ml, a culture temperature of 32°C, a shaker speed of 180rpm, and a culture time of 32 hours.

[0064] (2) Fermentation culture

[0065] A 500 mL baffle bottle has a liquid volume of 100 mL, an inoculum size of 4% (V / V), a temperature of 28° C., and a shaker rotation speed of 400 rpm for cultivation. When the bacterial growth is in the early logarithmic phase, add 0.05‰ vitamin B 1 , when the growth of the bacteria was in the early stage of the stationary phase, 0.02‰ of uracil nucleotides was added to accumulate the secondary metabolite, that is, pullulan.

[0066] (3) Separation of pullulan

[0067] After filtering out the bacterial cells in the fermentation broth, add three times of ethanol, stir, stand overnight at 4°C, centrifuge, rinse twice with absolute ethanol, and dry to obtain 75.6 g / L of whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com