Vacuum reaction chamber and vacuum processing equipment

A reaction chamber and vacuum technology, applied in vacuum evaporation plating, metal material coating process, ion implantation plating, etc., can solve the problems of reducing equipment utilization rate, inaccurate spectral detection, waste of manpower, etc., to reduce costs and manpower loss, guaranteed observation effect, and overall life extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

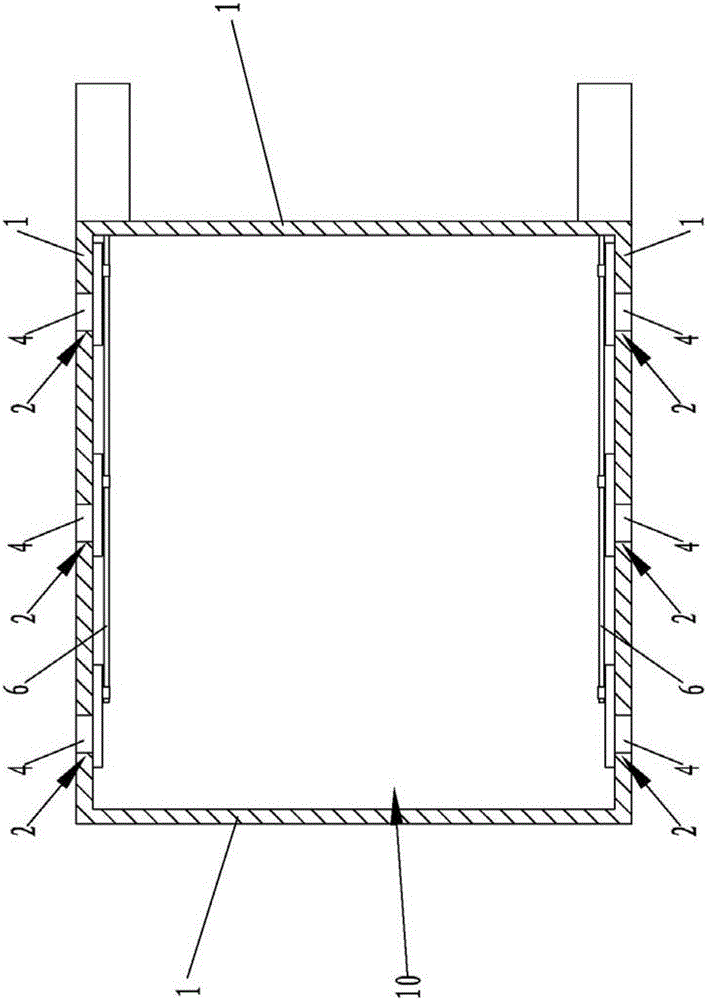

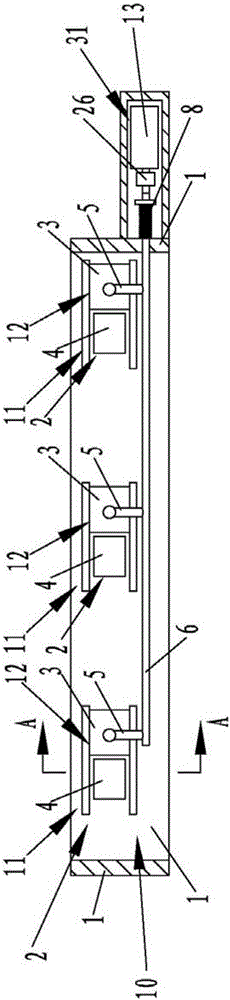

[0030] Such as figure 1 , figure 2 As shown, the embodiment of the vacuum reaction chamber of the present invention includes a plurality of wall plates 1 , and the plurality of wall plates 1 surround and form a chamber 10 for accommodating workpieces. Chamber 10 is rectangular. At least one wall plate 1 in the plurality of wall plates 1 is provided with an observation device 2, and the observation device 2 includes an observation window 4 arranged on the wall plate 1 and an observation window 4 arranged on the side of the wall plate 1 facing the inside of the chamber 10. It is used to block the shielding plate 3 of the observation window 4. The shielding plate 3 is located inside the chamber 10 . The blocking plate 3 can move between a first position 11 for blocking the observation window 4 and a second position 12 for not blocking the observation window 4 .

[0031] figure 2 The structure of the observation device 2 inside the chamber 10 is shown. In the embodiment of...

Embodiment 2

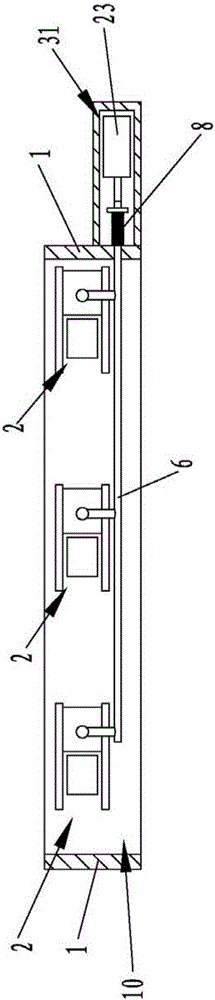

[0055] combine image 3 As shown, the difference between the embodiment of the vacuum reaction chamber of the present invention and the first embodiment is only the difference in power components, wherein the power component 31 of this embodiment is the cylinder 23, the piston rod of the cylinder 23 and the other end of the spring tube 8 Connection, the controller is connected with the cylinder 23, and the controller controls the movement of the shutter plate 3 between the first position 11 and the second position 12 by controlling the movement of the piston rod of the cylinder 23.

Embodiment 3

[0057] combine Figure 4 Shown, the embodiment of the vacuum reaction chamber of the present invention, wherein, one end of the spring tube 8 is connected with the end protruding from the inside of the chamber 10 of the movement rod 6, and the other end of the spring tube 8 is connected with a handle 25, and the handle 25 The shielding plate 3 is moved between the first position 11 and the second position 12 by driving the spring tube 8 to extend or compress.

[0058] The vacuum processing equipment of the present invention includes the vacuum reaction chamber of the present invention.

[0059] The vacuum reaction chamber of the present invention uses ceramic materials with high temperature resistance, corrosion resistance and ion bombardment resistance to make the shielding plate. When using the observation window for observation, the shielding plate can be opened manually or automatically; when the observation window is not used in normal production, the shielding plate can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com