Growing method for high-quality CuI crystals

A growth method and crystal technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of poor shape, size and size not mentioned, etc., to achieve good integrity, low cost, convenient and safe to use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

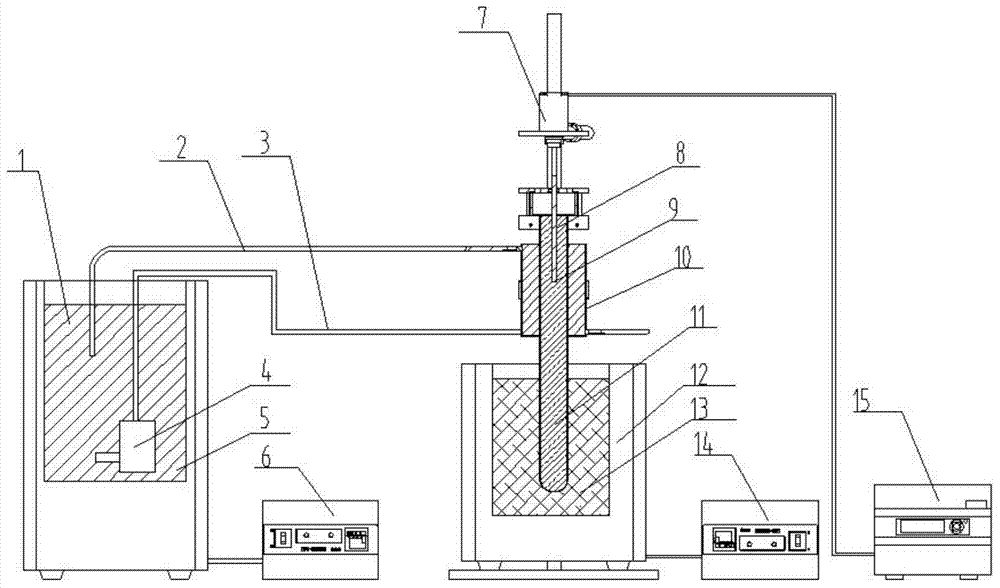

Method used

Image

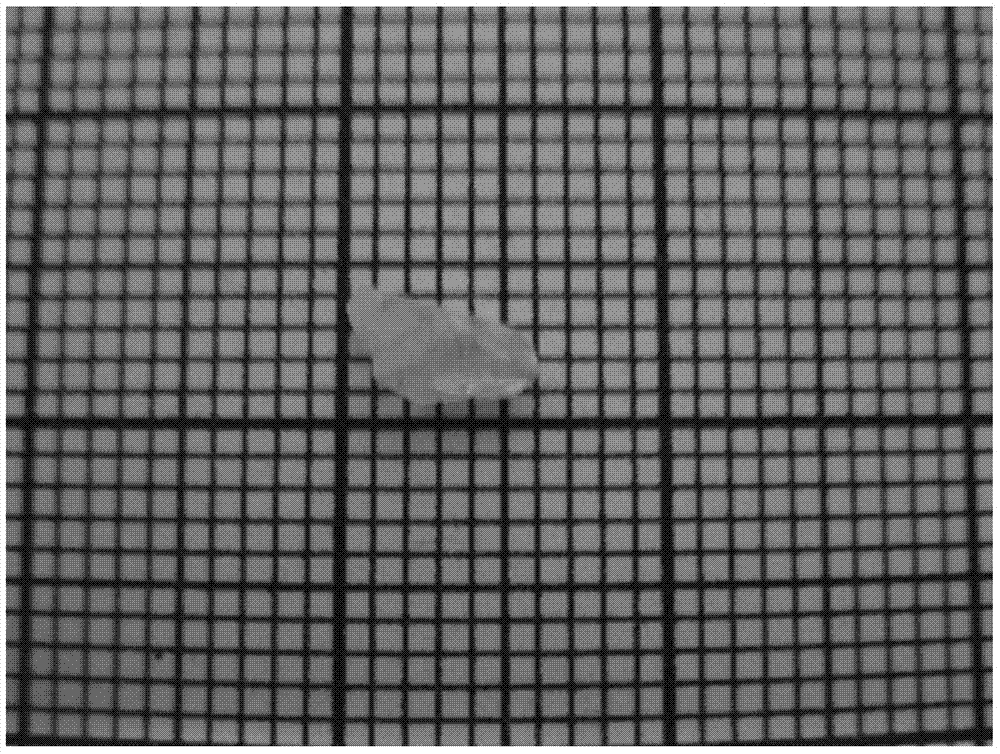

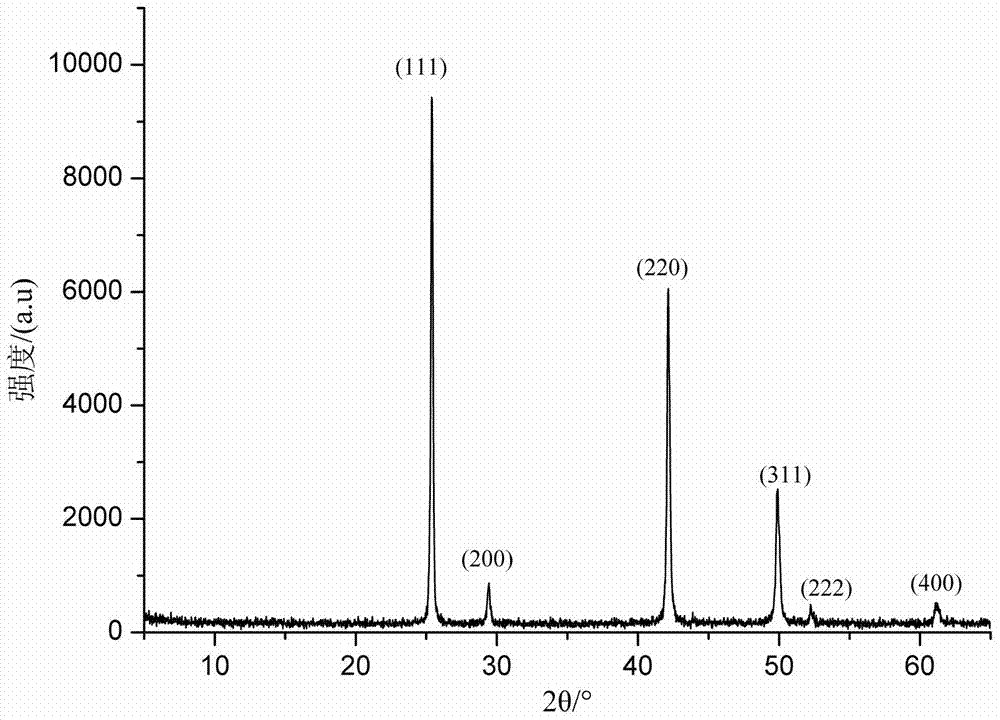

Examples

Embodiment Construction

[0020] Below in conjunction with specific implementation preferred scheme further illustrate how the present invention is realized:

[0021] 1. Preparation of Saturated Solution

[0022] Weigh analytically pure NH 4 I28.9880g is placed in a 125mL wide-mouth bottle, add 100mL high-purity water, stir at room temperature, and prepare 2M NH 4 I solution. To the prepared NH 4 Add 1.9684g of CuI powder into the I solution, heat to 70°C, stir for a period of time, the CuI powder is completely dissolved, and a saturated solution of CuI is obtained, and the solution is pale yellow at this time.

[0023] 2. Preparation of Growth Seeds

[0024] Spontaneous crystallization and cultivation of seed crystals were carried out by using an aqueous solution cooling method. Choose NH 4 The I (2M) solution was used as the solvent, and the copper sheet was used as the reducing agent. A saturated solution of CuI at 70°C was prepared in a 125mL jar with a paraffin oil seal, sealed with a cap, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com