Measuring method of deep-hole copper plating accelerant

A measurement method and accelerator technology, applied in the field of thin film material manufacturing, electrochemical technology application, and semiconductor manufacturing, can solve problems such as the inability to evaluate the cathode process to judge the effect and effect of additives, and achieve the effect of promoting industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

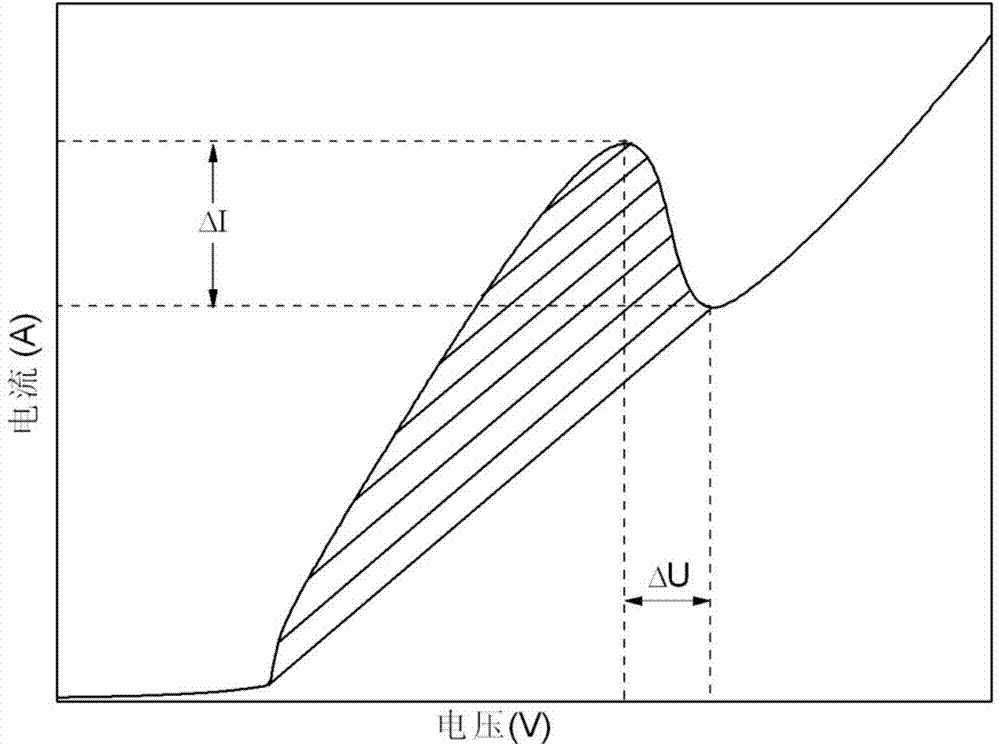

Method used

Image

Examples

Embodiment 1

[0028] This embodiment relates to a method for determining the content of a copper interconnect electroplating accelerator, and the specific steps are as follows:

[0029] (1) The Au electrode is used as the working electrode, the TSV copper plating solution is used as the electrolyte, the saturated calomel electrode is used as the reference electrode, and the platinum sheet is used as the counter electrode to form a three-electrode system.

[0030] (2) Measure the cathodic polarization curve of the basic plating solution, the composition of the basic plating solution: the concentration of copper ions is 40g / L, the concentration of chloride ions is 50ppm, and the pH value is 1;

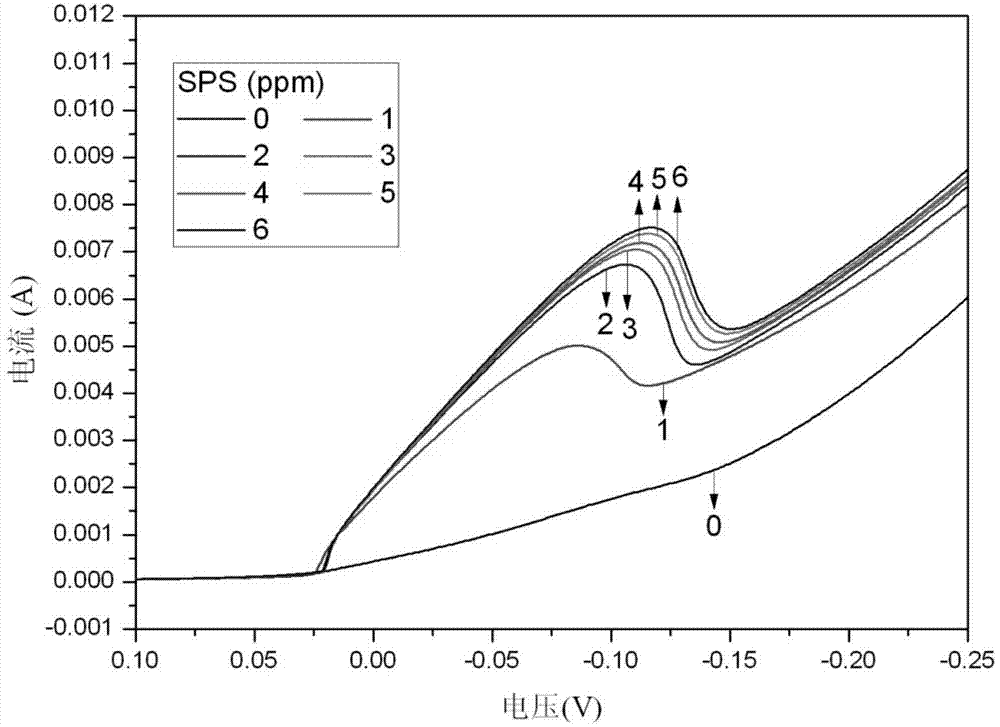

[0031] (3) Add 300ppm polyethylene glycol (PEG) to the basic plating solution, and measure its cathodic polarization curve, such as figure 2 (0), the inhibitory effect of PEG can be observed.

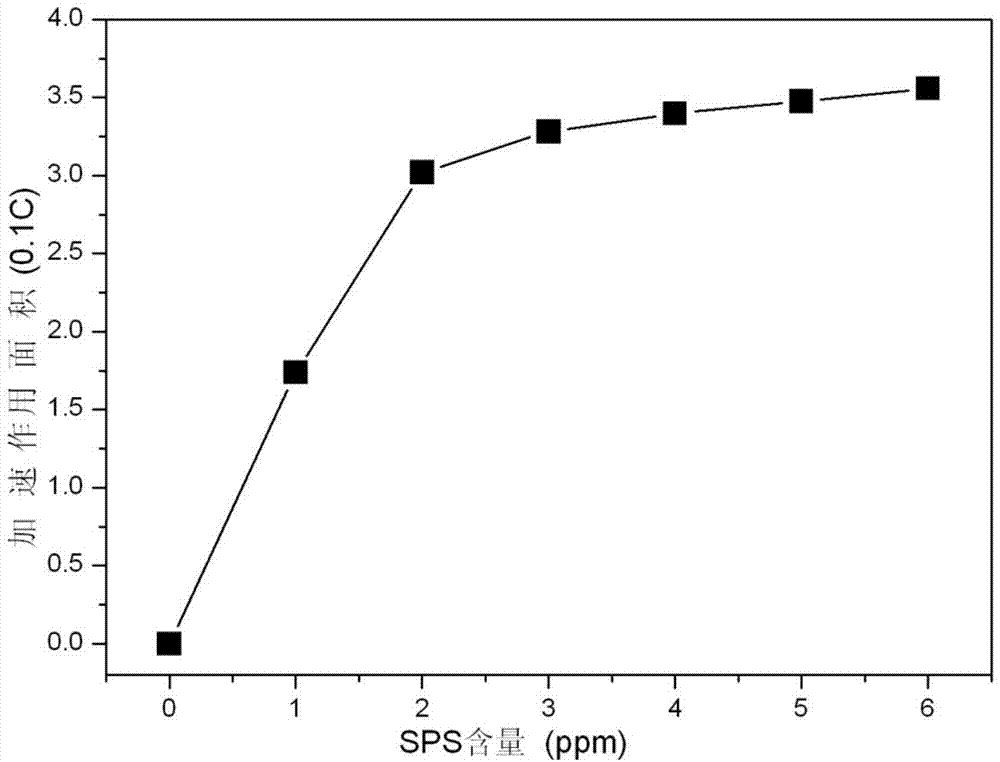

[0032] (4) Add 300ppm of PEG to the basic plating solution and keep the concentration constant, then add d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com