A system and method for heating an optically pumped bubble at different temperatures

A light-pumping and heating-light technology, which is applied in the direction of temperature control using electric methods and auxiliary controllers with auxiliary heating devices, can solve problems such as uneven heating, large temperature differences, and electromagnetic interference, and achieve Strengthen the uniformity of heating, balance the unevenness of heating, and improve the effect of polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

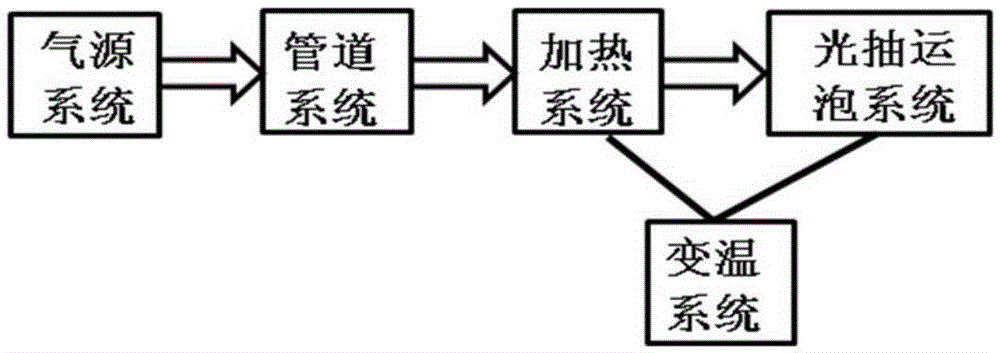

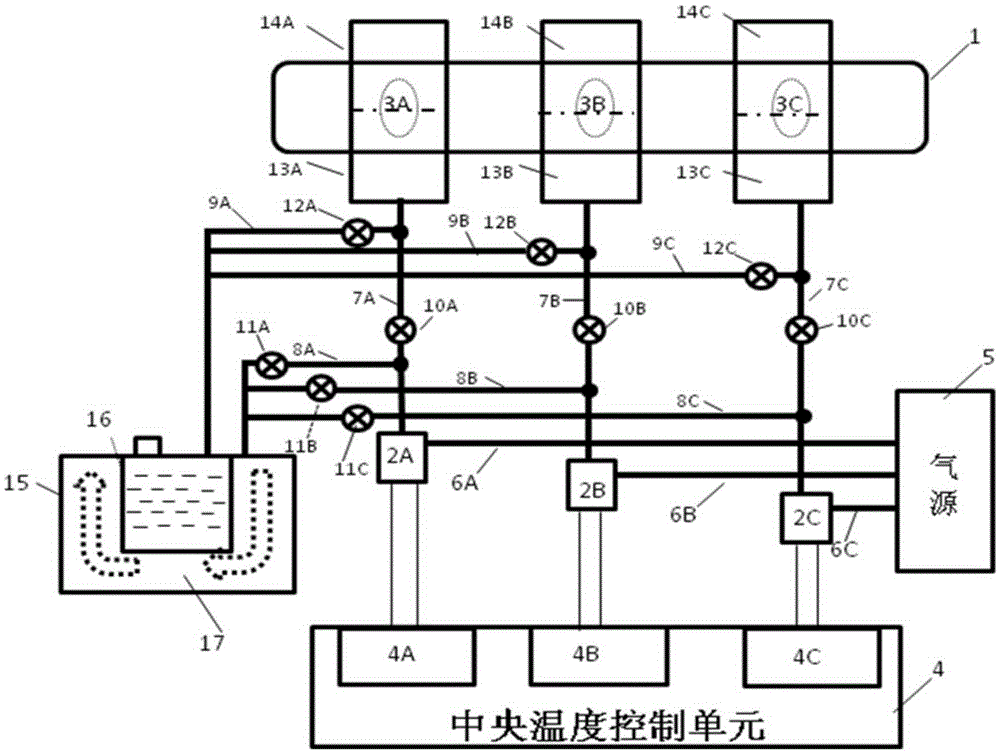

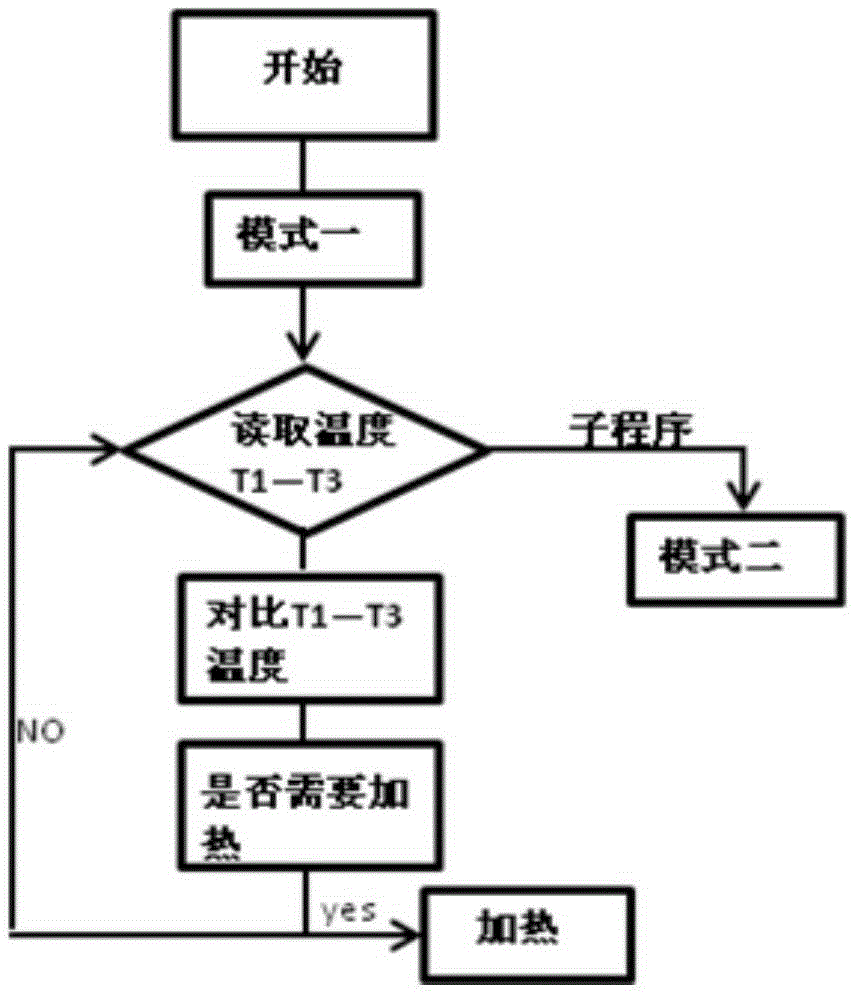

[0049] Such as figure 1 As shown, a system for heating optical pumping bubbles at different temperatures includes an air source, a pipeline system, a temperature changing system, a temperature control system, and an optical pumping bubble system. The air source system provides a certain flow of air through the pipeline system and is heated to the set temperature in the heating system to heat the light pumping bubble; the pipeline system is composed of a pipeline group and a valve group, and the pipeline system is the carrier of the air fluid. They will use various connection methods to direct heated hot air into the optical pumping bubble or use hot air to vaporize the liquid nitrogen in the liquid nitrogen storage device, and then introduce low-temperature nitrogen into the optical pumping bubble; in the piping system The function of the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com