Catalytic cracking absorption stabilizing unit optimization processing method based on process simulation software

A process simulation and catalytic cracking technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as high operating costs, economic constraints, and losses outweighed by gains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

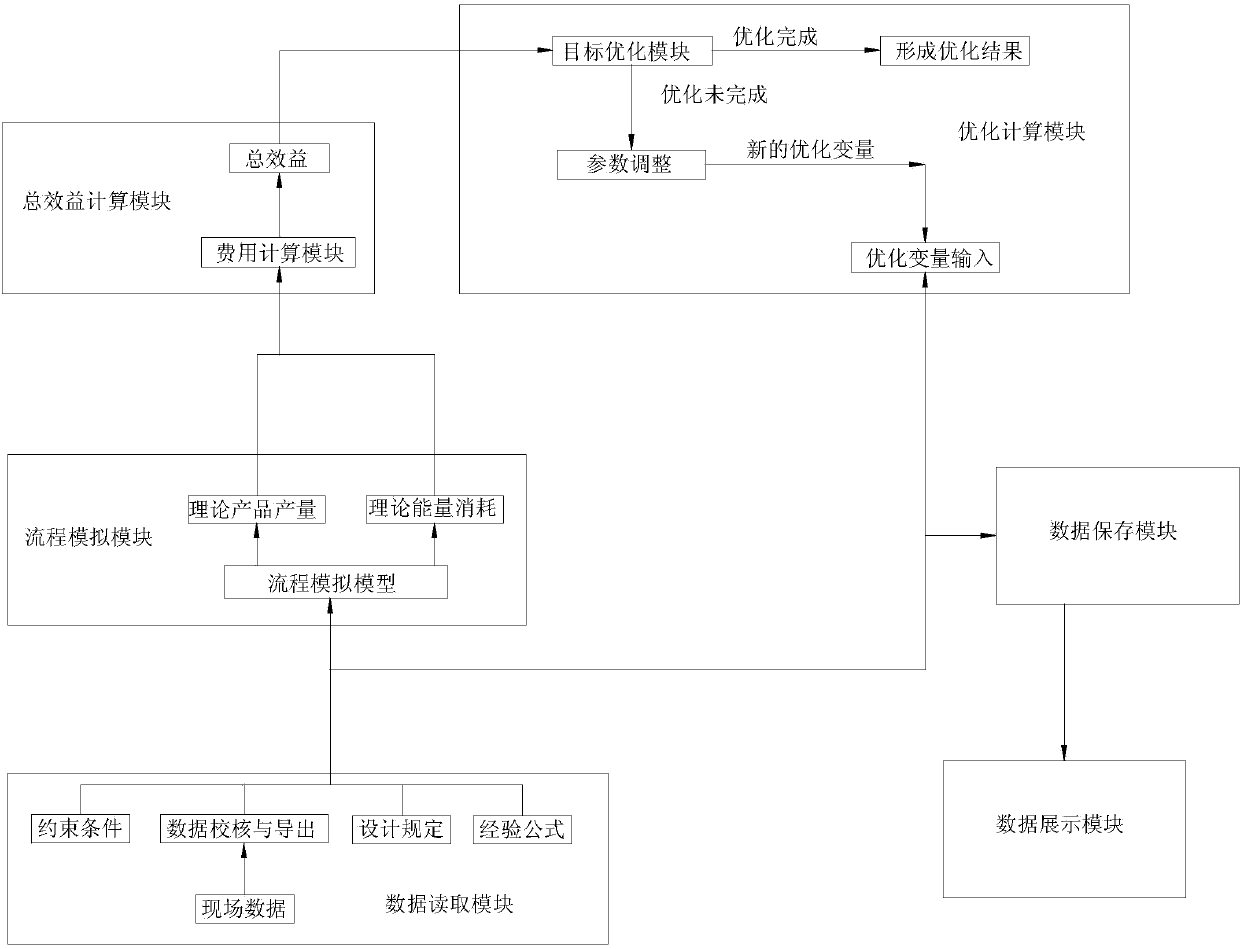

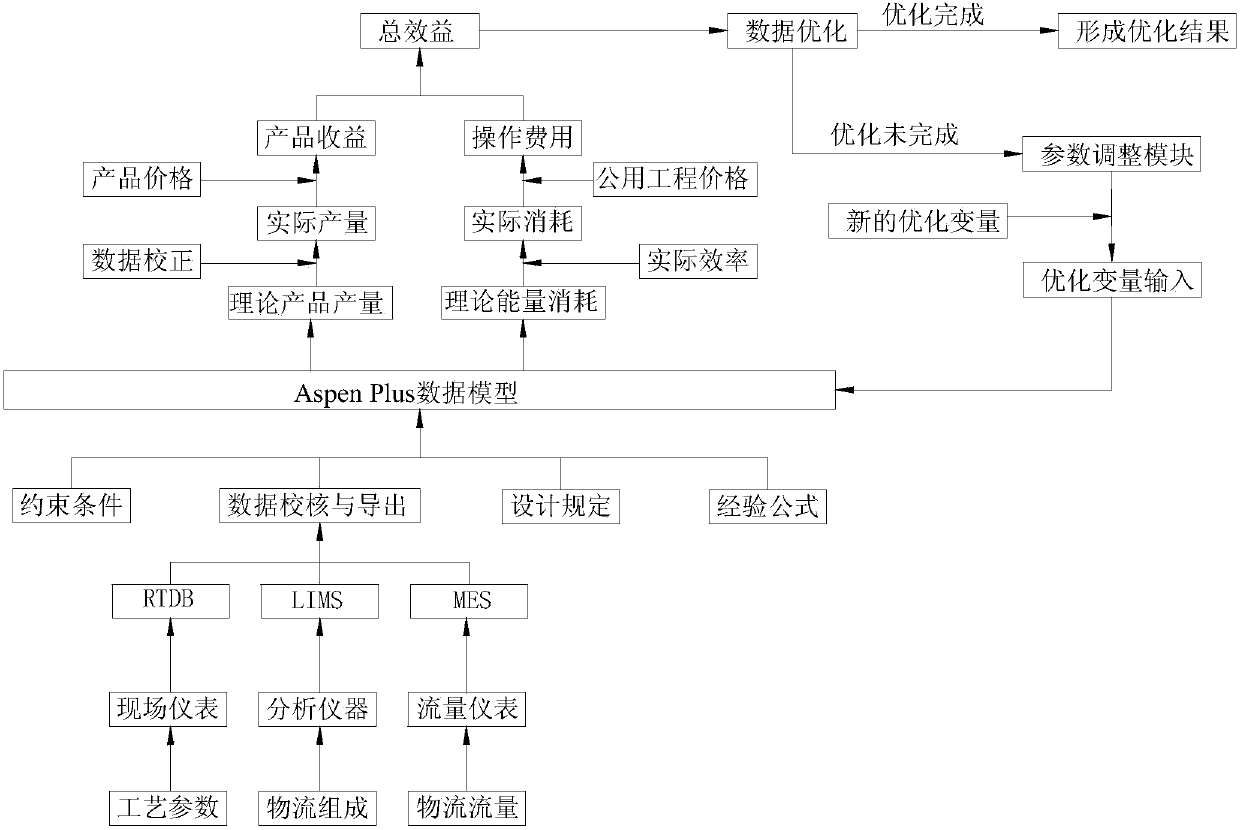

Method used

Image

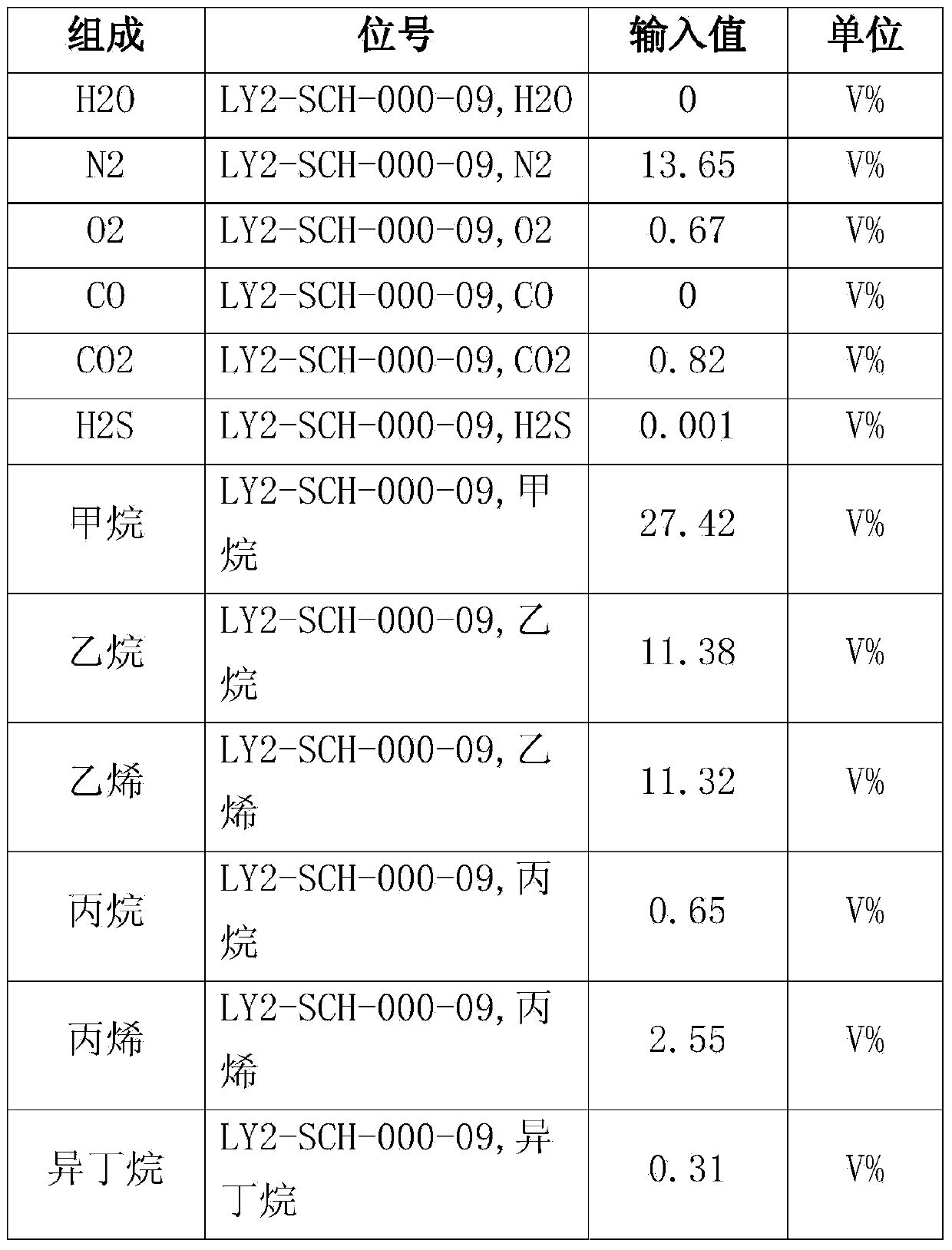

Examples

Embodiment 1

[0113] Adjustment of reabsorption tower feed temperature: The reabsorption tower feed of a plant’s absorption stabilization system is a single stream of condensed oil tower top hot feed, the original feed temperature is 68.5°C, and the bottom reboiler uses lean absorption oil and a One medium is used as a heat source, and the excess heat in one medium produces 0.3MPa steam, and circulating water is used for cooling when the steam is excess. After the simulation calculation analysis, the new feed temperature obtained after the optimization solution is 62°C. If the raw feed temperature is too high, after the feed temperature of the desorption tower drops by 7°C, the temperature at the bottom of the tower drops, and the heat load drops, which is effectively reduced.

[0114] The detailed results are as follows:

[0115] Due to the cold feed, the load of the reboiler of the desorption tower increases by 500KW, and the heat load of the feed heat exchanger of the desorption tower d...

Embodiment 2

[0117] Supplementary absorbent dosage adjustment: As a supplement to the optimization of Example 1, the flow of supplementary absorbent was optimized again, and after optimization, the flow increased from 43t / h to 49t / h. The C3 content in the dry gas decreases again. After the implementation, the effect is obvious, and the economic benefit is also increased by about 25¥ / hr.

[0118] The reason is: after the flow rate of the circulating desorbing gas decreases, the total amount of gas and liquid in the absorption tower decreases, and there is room for the independent variable to supplement the absorbent.

[0119] Adding supplementary absorbent can increase the concentration difference of light components in the vapor-liquid two-phase, thereby increasing the mass transfer driving force in the absorption process; the heat load of the reboiler in the stabilization tower has increased, but the RVP requirements for gasoline produced in winter are not high. High, stable column reboi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com