Self-circulating heat dissipating device of 5MW doubly-fed air-cooled and water-cooled wind generator

A kind of technology of cooling device and generator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with specific embodiment and accompanying drawing, the present invention is further described:

[0017] 5MW double-fed air-water-cooled wind turbine self-circulation cooling device, its specific structure is as follows:

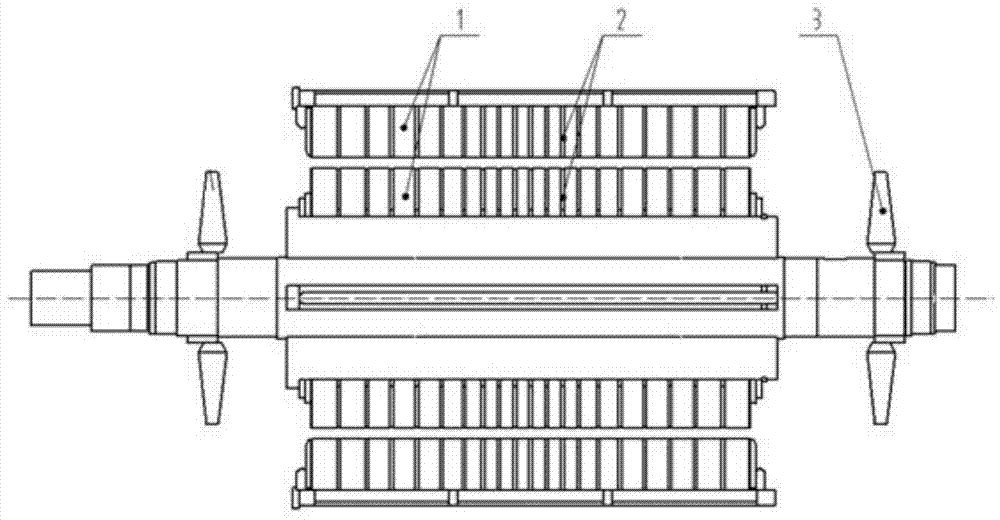

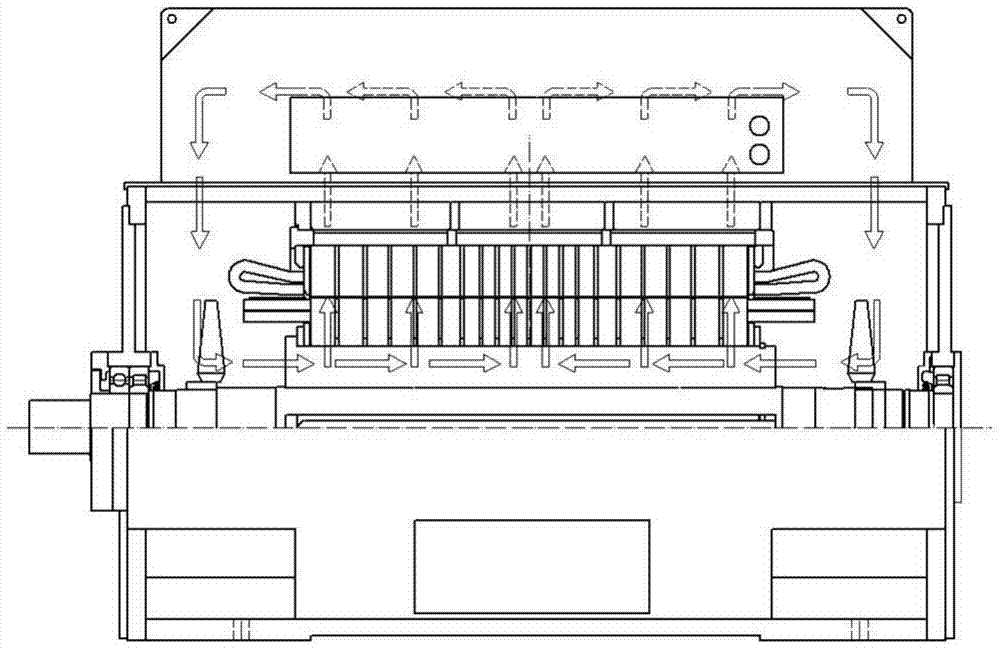

[0018] The stator and rotor cores adopt a segmented structure. During the lamination process of the rotor cores 1, a radial ventilation channel is formed between each segment of the rotor cores 1 with the ventilation slot plate 2, and the rotor core 1 is divided into lengths by Segments that gradually become shorter from both ends to the middle, and make the rotor core 1 form an air channel structure with unequal spacing that is symmetrical from the middle;

[0019] On the shaft of the motor outside the two ends of the rotor core 1, there are respectively arranged axial flow fans 3 to supply air to the middle of the rotor core 1. When the motor shaft rotates, the two ends of the rotor core 1 form a large wind pressure from the outs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com