Colored metal-based printed board and manufacturing method thereof

A metal substrate, color metal technology, applied in the direction of printed circuit manufacturing, circuit substrate materials, printed circuits, etc., can solve problems such as thermal sensitivity and poor photosensitivity effect, and achieve the effect of increasing visual effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

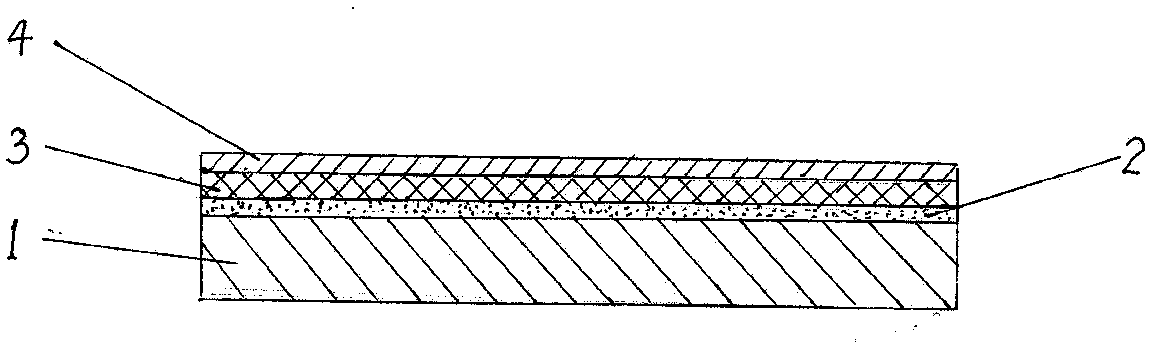

[0046] Such as figure 1 As shown, the thickness of the metal substrate 1 is 0.3-5mm. Firstly, the metal substrate 1 is subjected to anodic oxidation treatment and surface coloring treatment, and an insulating chemical conversion film 2 is formed on the surface of the metal substrate 1, and then hot-pressed on the surface of the metal substrate 1 in sequence. After bonding the insulating dielectric layer 3 and the copper foil layer 4, the metal-based copper clad laminate is formed. After the surface of the copper foil layer 4 of the metal-based copper-clad laminate is subjected to operations such as pasting film, transferring circuit patterns, etching, and film removal, the colored metal-based printed board of the present invention is formed.

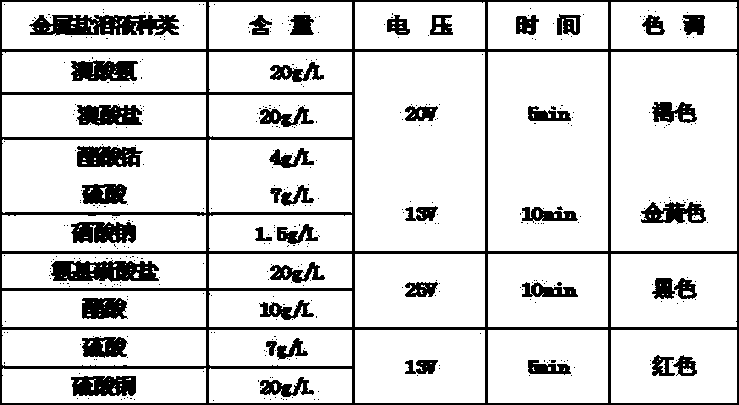

[0047] The surface coloring treatment of metal substrate 1 can adopt CuSO 4 Electrolytic coloring is carried out as an electrolytic solution, or electrostatic spraying is used for spraying coloring, or organic dyes are used for adsorpti...

Embodiment 2

[0049] The manufacturing method of the colored metal-based printed board of the present invention comprises the following steps:

[0050] 1. Carry out anodic oxidation and surface coloring treatment on the metal substrate with a thickness of 0.3-5mm, and then pass it in a concentrated sulfuric acid solution with a concentration of 22g / l at 1-1.5A / dm 2 Under the intensity of direct current, immerse the metal substrate for 10-15 minutes, and then immerse it in a saturated potassium dichromate solution at a temperature of 95-100°C for 5-20 minutes to generate insulation on the surface of the metal substrate. chemical conversion coating. The anodic oxidation and surface coloring treatment of the metal substrate is mainly through chemical and electrochemical treatment of the surface of the metal substrate to make it have a certain roughness, and to form a high-insulation chemical conversion film with a certain thickness on the surface , so that the resin film layer has high resist...

Embodiment 3

[0080] The manufacturing method of the colored metal-based printed board of this embodiment is basically the same as that of Embodiment 2, except that the surface coloring process of the metal substrate is sprayed and colored by electrostatic spraying, and the specific process is:

[0081] ① Degreasing: Put the metal substrate in H 2 SO 2 Soak in water for 3 to 5 minutes to degrease.

[0082] ② Alkaline cleaning: Soak the degreased metal substrate in a sodium hydroxide solution with a mass concentration of 45-85 g / L for 5-15 minutes, and perform alkaline cleaning.

[0083] ③ Illumination: Immerse the metal substrate after alkali cleaning into H2O with a concentration of 200-250g / L 2 SO 2 with H at a concentration of 3-5 g / L 2 NO 3 in the mixed solution for 3-5 minutes to neutralize the alkaline metal salts on the surface of the metal substrate and clean the surface of the metal substrate.

[0084] ④ Anodizing: Put the surface-treated metal substrate in concentrated sulfu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com