Grain flexible bionic stripping threshing device

A threshing device, rice and wheat technology, applied in threshing equipment, applications, agricultural machinery and tools, etc., can solve the problems of increasing the degree of mixing of straw and ear heads, harvesting omission loss, low grain removal rate, etc., to reduce the grain surface Effects of preventing damage, ensuring surface quality, and improving roughing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

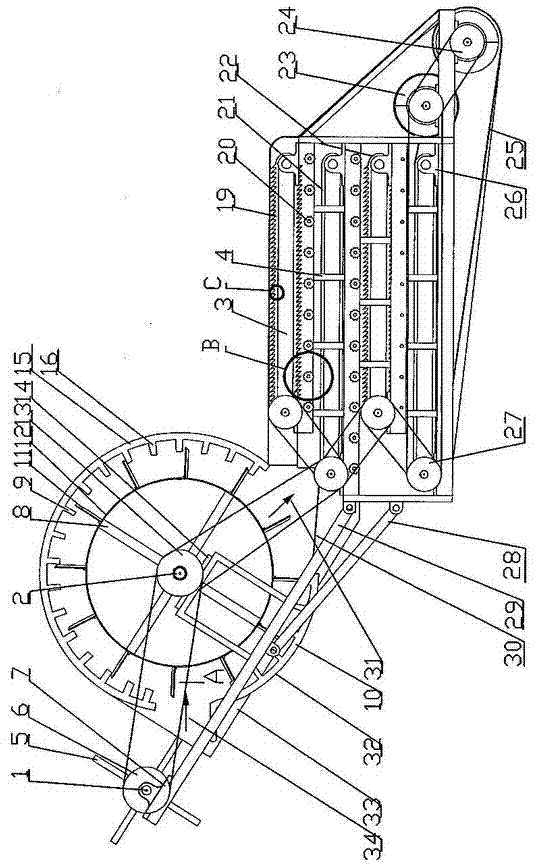

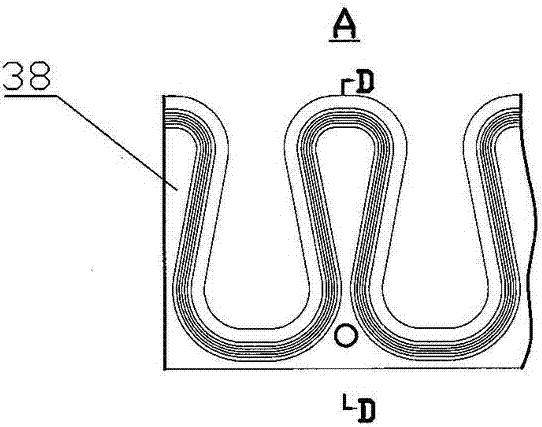

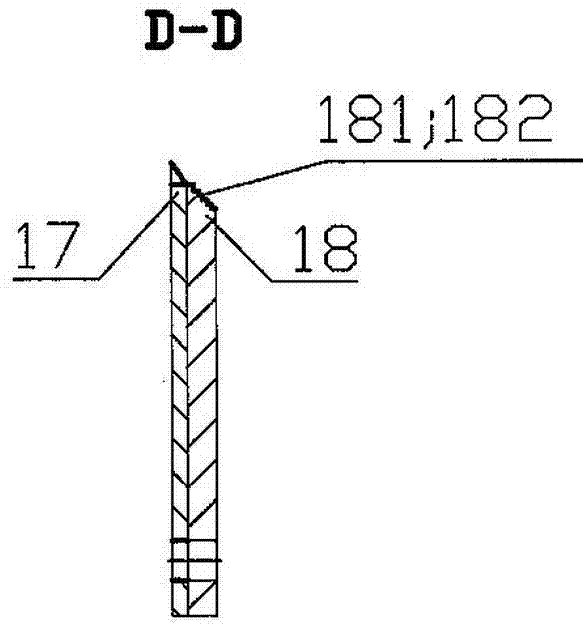

[0028] see Figure 1 to Figure 5As shown, in this embodiment, the feeding brush roller 1, the ear picking and rough removing drum 2, the fine removing cleaning bin 3, the frame 4, the fine removing toothed belt 19, the fine removing hole belt 21, the grain conveying and stirring The dragon 24 and the grain guide plate 25 are formed. The feeding brush roller 1 is fixed on the front end of the rocker arm 29 through the brush bearing seat 7, and the ear picking and rough stripping drum 2 is fixed on the rear end of the rocker arm 29 through the rough stripping bearing seat 14. The cleaning bin 3 is fixed at the rear and lower part of the ear picking and coarse stripping drum 2, and is fixed on the frame 4 through the fine stripping bearing seat 26. The rear and bottom; the feeding brush 5 is radially evenly distributed on the outside of the brush drum 6; The outer side of the metal cylinder 12 drives the rough removal roller 8 to rotate through the rough removal pulley 13; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com