Forward osmosis concentration system and concentration method

A concentration system and forward osmosis technology, applied in the field of fruit juice concentration, can solve the problems of high energy consumption in production and operation, serious membrane pollution, difficult long-term storage, etc., and achieve the effects of saving resources, abundant sources and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

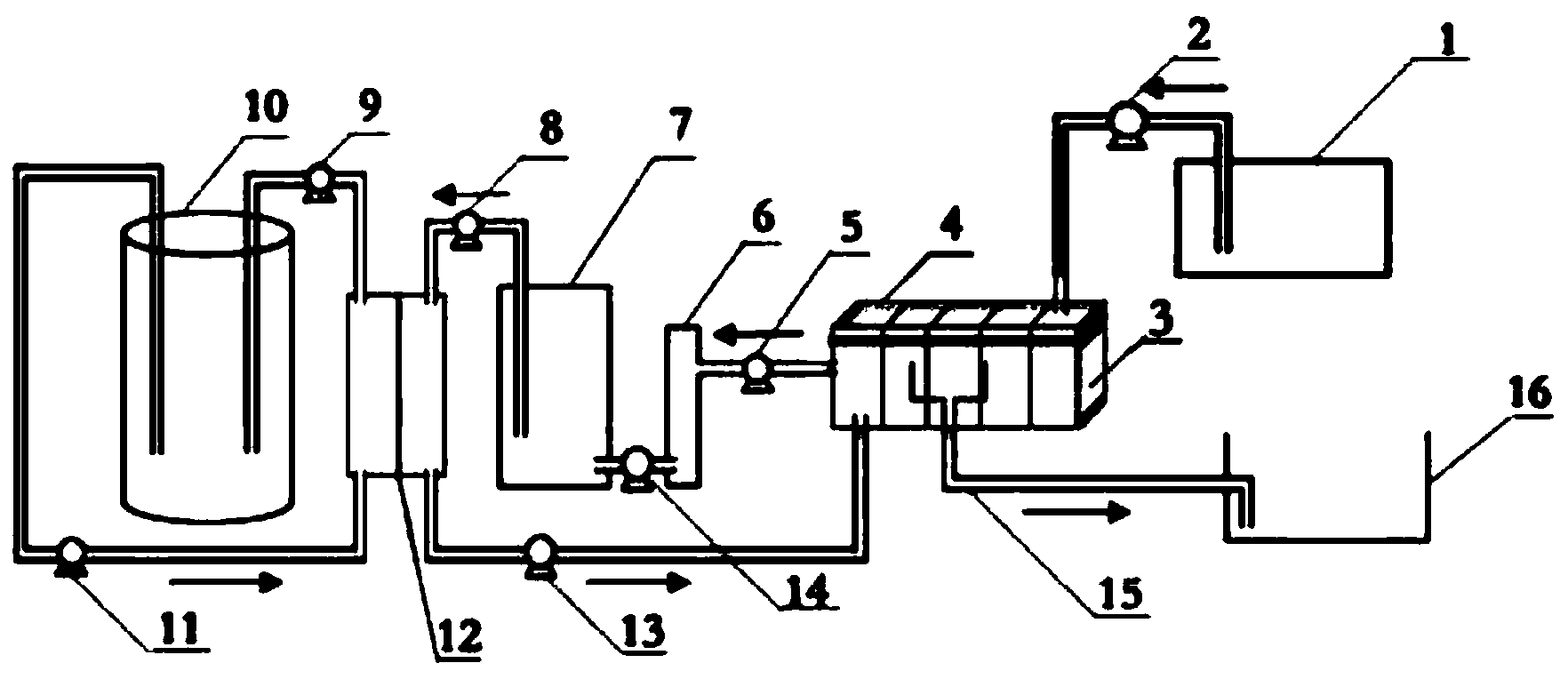

[0036] Such as figure 1 The shown forward osmosis concentration system consists of 1, a seawater pretreatment clarification tank 2, a first circulation extraction pump 3, a multi-stage draw liquid evaporation adjustment tank 4, a transparent glass 5, a second circulation extraction pump 6, a secondary filtration device 7, Draw solution storage tank 8, draw solution injection pump 9, concentrate solution pump 10, concentration tank 11, concentrate solution injection pump 12, forward osmosis device 13, draw solution pump, 14, third circulation pump, 15, water collection Pipeline 16, sump form.

[0037] The connection relationship of each component in the system is:

[0038] The first circulation pump 2 is connected between the seawater pretreatment pool 1 and the draw liquid evaporation adjustment pool 3, and the transparent glass 4 is installed on the upper part of the draw liquid evaporation adjustment pool 3, and the outlet of the evaporation liquid on the draw liquid evapor...

Embodiment 2

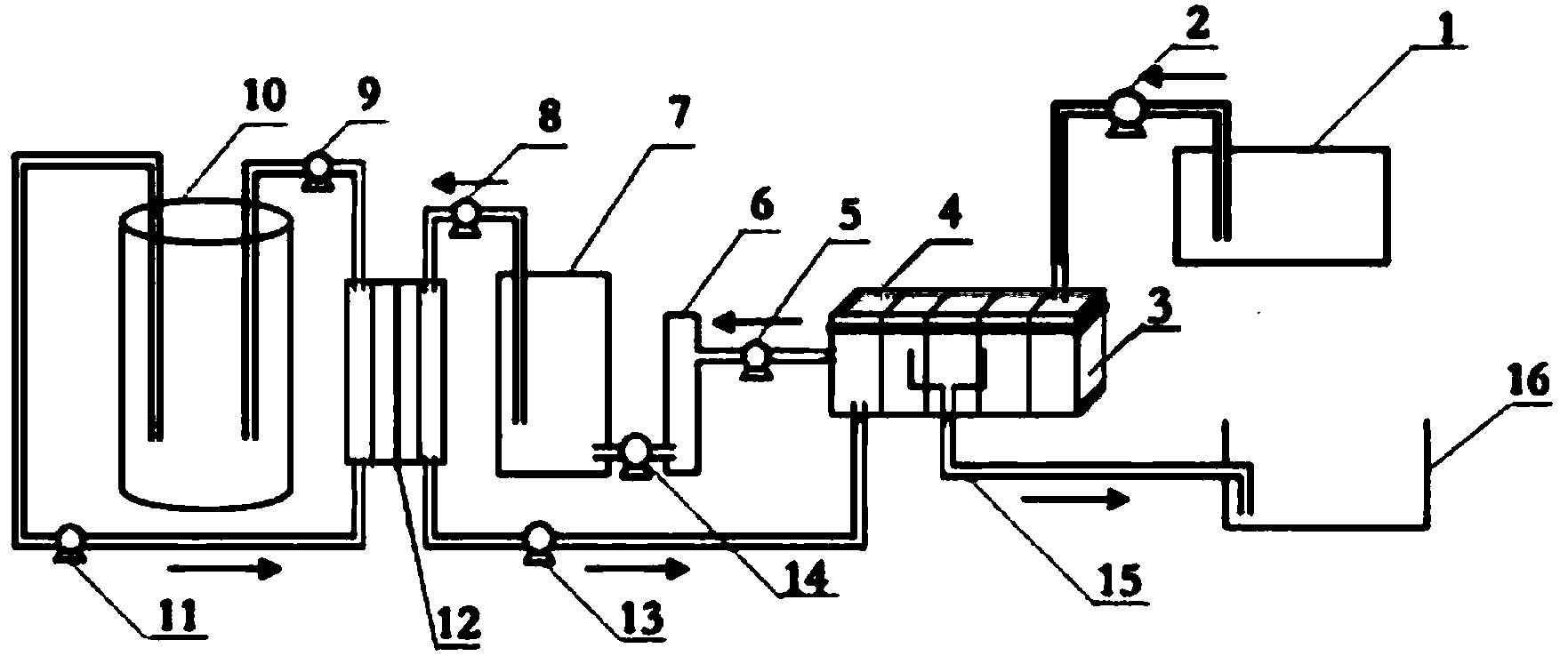

[0056] Such as figure 2 The difference between the present embodiment and the first embodiment of the forward osmosis concentrated tomato juice system shown is that the membrane module of the forward osmosis device 12 is composed of four modules connected in series, and its operation mode is exactly the same as that of the first embodiment. In this implementation case, four components are connected in series to obtain tomato juice with higher concentration, which saves energy and facilitates storage and transportation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com