Platinum/attapulgite nano supported catalyst, and preparation method and application thereof

A technology of supporting catalysts and attapulgite, which is applied in the chemical field, can solve problems such as post-processing troubles and complex reactions, and achieve the effects of easy separation, high catalytic activity, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

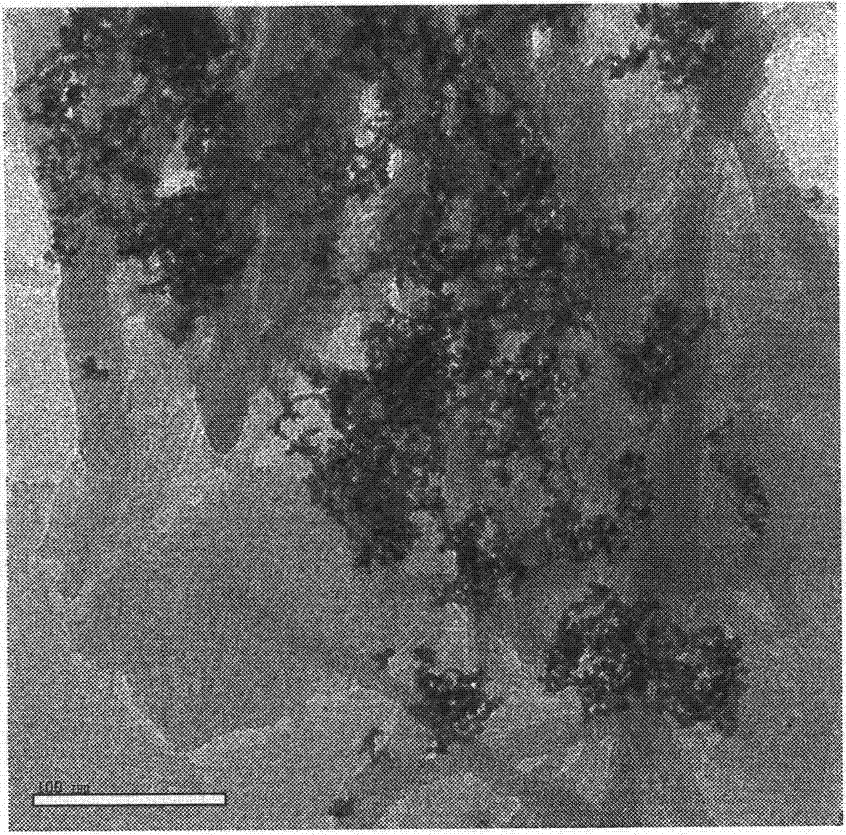

Image

Examples

Embodiment 1

[0024] (1) Pretreatment of attapulgite

[0025] The attapulgite is pulverized and ground with a mortar, and the ground attapulgite is screened with a 200-300 mesh sieve. Add 80 ml of hydrochloric acid solution with a concentration of about 5% to 5 grams of screened attapulgite, reflux at 70°C for 3 hours, and wash with deionized water until PH=6.0. Vacuum-dried in a vacuum desiccator until it was dried to a constant weight, and used for subsequent experiments.

[0026] (2) Preparation of Platinum Nanosol

[0027] In a 500ml beaker, accurately measure 3.86×10 -3 mol / L chloroplatinic acid aqueous solution 15 milliliters, add 150 milliliters of deionized water, then add 4.18×10 -4 20 ml of mol / L polyvinylpyrrolidone aqueous solution, the mixture was stirred on a magnetic stirrer for about 30 minutes, and 0.03 g of sodium borohydride was added to prepare a platinum sol.

[0028] (3) Preparation of Pt / ATP nano-catalyst

[0029] Accurately weigh 0.7507 g of the attapulgite trea...

Embodiment 2

[0038] (1) Pretreatment of attapulgite

[0039] The attapulgite is pulverized and ground with a mortar, and the ground attapulgite is screened with a 200-mesh sieve. Add 120 milliliters of 5% sulfuric acid solution in 10 grams of screened attapulgite, after refluxing at 80 DEG C for 4 hours, clean with deionized water until pH=7.0, after cleaning, the product obtained will Vacuum-dry in a vacuum desiccator until it reaches a constant weight for subsequent experiments.

[0040] (2) Preparation of Platinum Nanosol

[0041] In a 500ml beaker, accurately measure 3.86×10 -3 mol / L chloroplatinic acid aqueous solution 10 ml, add 100 ml deionized water, then add 2.76×10 -4 21 ml of mol / L polyvinylpyrrolidone aqueous solution, the mixture was stirred on a magnetic stirrer for about 30 minutes, and 0.022 g of potassium borohydride was added to prepare a platinum sol.

[0042] (3) Preparation of Pt / ATP nano-catalyst

[0043] Accurately weigh 0.7510 g of the attapulgite treated in (1...

Embodiment 3

[0051] (1) Pretreatment of attapulgite

[0052]The attapulgite is pulverized and ground with a mortar, and the ground attapulgite is screened with a 300-mesh sieve. Add 120 milliliters of 7% hydrochloric acid solution to 12 grams of screened attapulgite, and after reflux at 75° C. for 5 hours, clean with deionized water until pH=8.0. Vacuum-dry in a vacuum desiccator until it reaches a constant weight for subsequent experiments.

[0053] (2) Preparation of Platinum Nanosol

[0054] In a 500ml beaker, accurately measure 3.86×10 -3 mol / L chloroplatinic acid aqueous solution 10 ml, add 100 ml deionized water, then add 2.76×10 -4 21 ml of mol / L polyvinylpyrrolidone aqueous solution, the mixture was stirred on a magnetic stirrer for about 40 minutes, and 0.022 g of potassium borohydride was added to prepare a platinum sol.

[0055] (3) Preparation of Pt / ATP nano-catalyst

[0056] Accurately weigh 0.7610 g of the attapulgite treated in (1) into the platinum sol prepared above, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com