Device for methanol reforming hydrogen production by utilizing waste heat of automobile exhaust gas

A technology for producing hydrogen from automobile exhaust and reforming, which is applied in exhaust devices, noise reduction devices, hydrogen, etc., can solve problems such as energy loss and environmental pollution, reduce pollutant emissions, facilitate installation and disassembly, and increase energy The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below with reference to the drawings and embodiments.

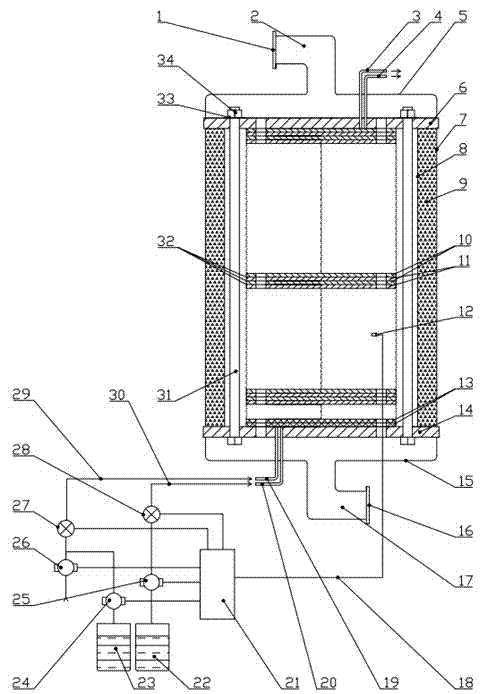

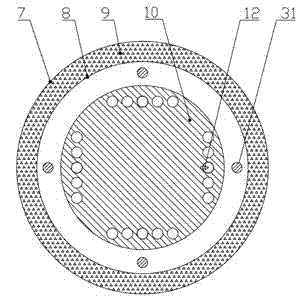

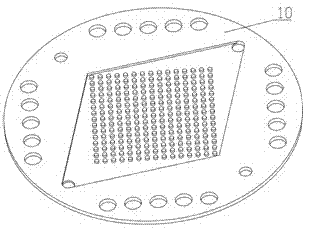

[0026] The invention provides a device for methanol reforming to produce hydrogen by using the waste heat of automobile exhaust gas. Such as figure 1 , figure 2 As shown, it includes: exhaust gas inlet flange 1, exhaust gas inlet pipe 2, reforming reaction product output pipe 3, combustion reaction product output pipe 4, exhaust gas inlet pipe shell 5, reaction body upper cover 6, reaction body shell 7, Reaction main body inner shell 8, thermal insulation ceramic wool 9, reforming reaction layer 10, combustion reaction layer 11, thermocouple 12, methanol water evaporation layer 13, reaction main body lower cover 14, exhaust gas outlet pipe shell 15, exhaust gas outlet flange 16. Exhaust gas outlet pipe 17, temperature signal line 18, combustion reaction fuel supply pipe 19, reforming reaction fuel supply pipe 20, electronic control unit 21, methanol water stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com