Low-compression permanent deformation silicone rubber composition and preparation method thereof

A technology of silicone rubber composition and compression permanent deformation, which is applied in the field of silicone rubber and can solve the problems of sacrificing the physical and mechanical properties of the silicone rubber composition and losing the translucent natural color of the rubber material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

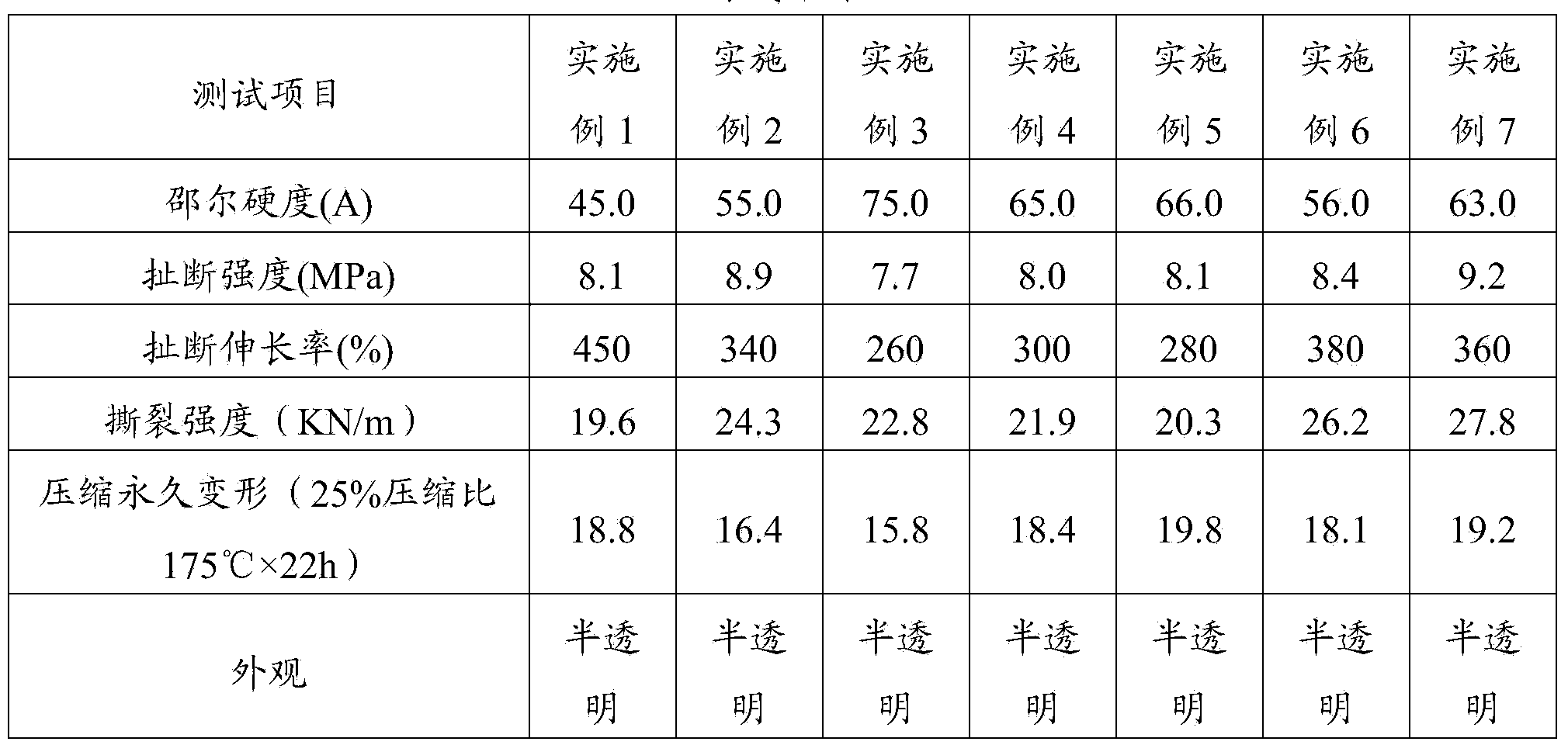

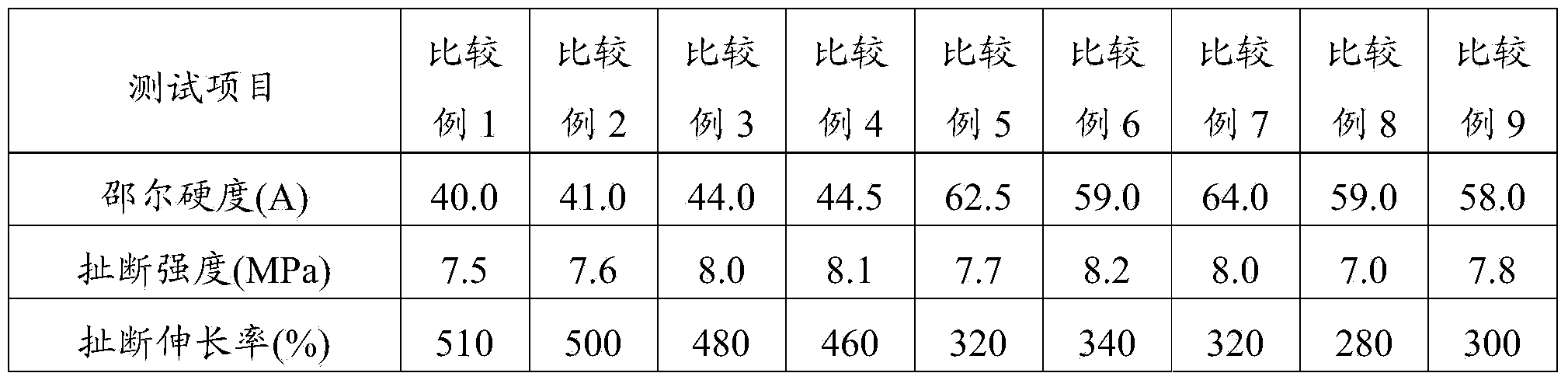

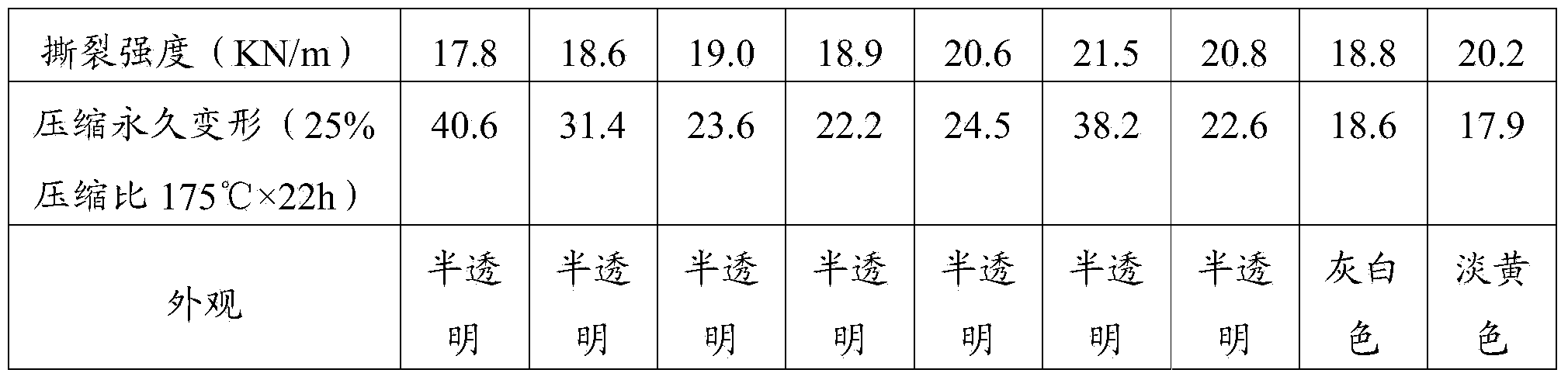

Examples

preparation example Construction

[0059] The invention provides a method for preparing a low compression set silicone rubber composition, comprising the following steps:

[0060] a) Mixing methyl vinyl silicone rubber, compression set regulator, structuring control agent and internal mold release agent to obtain the first mixed material, the vinyl molar content of the methyl vinyl silicone rubber is 0.09%~ 0.50%;

[0061] b) adding the reinforcing filler into the first mixed material in the step a) for 3 to 10 times, and obtaining the second mixed material after static treatment;

[0062] c) subjecting the second mixed material obtained in step b) to high-temperature banburying heat treatment to obtain a mixed material;

[0063] d) mixing the compounded material obtained in the step c) with a vulcanizing agent and a vulcanizing aid, and vulcanizing to obtain a low compression set silicone rubber composition.

[0064] The present invention mixes the methyl vinyl silicone rubber, the compression set regulator,...

Embodiment 1

[0083] 11) In terms of parts by mass, when the temperature of the kneader is 50°C, 100 parts of methyl vinyl silicone rubber with a dimethyl vinyl end cap, a molecular weight of 650,000, and a vinyl molar content of 0.09%, 40 parts The specific surface area is 175m 2 / g precipitated silica, 1.5 parts of hydroxy silicone oil with kinematic viscosity of 25cst, 0.5 part of vinyl hydroxy silicone oil with kinematic viscosity of 30cst, 0.5 part of vinyl triethoxysilane, 0.05 part of magnesium stearate, kneaded Mix evenly in the machine, and the precipitated white carbon black is added in four times, and the amount of precipitated white carbon black added each time is 35%, 30%, 20%, and 15% respectively. Leave for 4 hours.

[0084] 12) Mix the parked rubber in a kneader at 160°C for 2.5 hours, and carry out vacuum mixing for 1.0 hour during the mixing process. The vacuum degree is not higher than 200Pa to obtain a mixed rubber.

[0085] 13) Mix 100 parts of rubber compound with 0....

Embodiment 2

[0088] 21) In terms of parts by weight, when the temperature of the kneader is 65°C, 100 parts of methyl vinyl silicone rubber with a dimethyl vinyl end cap, a molecular weight of 700,000, and a vinyl molar content of 0.16%, 35 parts The specific surface area is 175m 2 / g of precipitated silica, 10 parts specific surface area is 150m 2 / g of vapor-phase precipitation method silica, 3.0 parts of diphenyl dihydroxy silicone oil, 1.0 parts of vinyl hydroxy silicone oil with a kinematic viscosity of 30cst, 0.3 parts of vinyl triethoxysilane, and 0.1 parts of stearic acid are added to the kneader Mix evenly in the medium, and the precipitated white carbon black is added in five times, and the amount of reinforcing filler added each time is 35%, 25%, 20%, 10%, and 10% respectively. Leave for 6 hours.

[0089] 22) Put the parked rubber material in the kneader at 170°C for 3.5 hours, and carry out 2.0 hours of vacuum mixing, the vacuum degree is not higher than 200Pa, to obtain the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com