Stable type finished warm-mixing rubber modified asphalt and preparation method thereof

A kind of rubber modified and stable technology, used in building insulation materials, building components, buildings and other directions, can solve the problems of poor aging resistance, high design requirements for mixture ratio, and difficult construction, and achieve the effect of wide application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The stable finished warm-mix rubber-modified asphalt of the present invention is composed of various components in mass fraction, 76% of 50# base asphalt, 1% of powdered styrene-butadiene rubber, 16% of 30-mesh desulfurized rubber powder, 1% of stable agent, 3% liquid polybutadiene rubber toughening agent and 3% solid oil volume warm mix agent. The stabilizer is composed of the following components in mass fraction, 2% sulfur, 2% divinylbenzene and 96% furfural oil.

[0031] The preparation process steps are as follows:

[0032] (1) Soak the 30-mesh desulfurization waste rubber powder in 50# base asphalt at 140°C for 25min to make it initially disperse and swell, and heat it in an oil bath;

[0033] (2) Homogenization treatment is carried out by using three-dimensional frequency conversion pre-shearing, and then the 50# base asphalt mixed with waste rubber powder is sheared and refined by a high-speed shearing emulsifier, the shearing speed is 3500rpm, and the shearing...

Embodiment 2

[0036] The stable finished warm-mix rubber-modified asphalt of the present invention is composed of various components in mass fraction, 78% of 50# base asphalt, 1% of powdered styrene-butadiene rubber, 16% of 30-mesh desulfurized rubber powder, 1% of stable agent, 2% liquid polybutadiene rubber toughening agent and 2% solid oil volume warm mix agent. The stabilizer is composed of the following components in mass fraction, 1.5% sulfur, 1.5% divinylbenzene and 97% furfural oil.

[0037] The preparation process steps are as follows:

[0038] (1) Soak the 30-mesh desulfurization waste rubber powder in 50# base asphalt at 140°C for 25min to make it initially disperse and swell, and heat it in an oil bath;

[0039] (2) Homogenize by using three-dimensional frequency conversion pre-shearing, and then use a high-speed shearing emulsifier to shear and refine the 50# base asphalt mixed with waste rubber powder, the shearing speed is 4000rpm, and the shearing temperature is 160℃:

[004...

Embodiment 3

[0042] The stable finished warm-mix rubber-modified asphalt of the present invention is composed of various components in mass fraction, 76% of 50# base asphalt, 0.5% of powdered styrene-butadiene rubber, 16% of 30-mesh desulfurized rubber powder, 1.5% of stabilized agent, 3% liquid polybutadiene rubber toughening agent and 3% solid oil volume warm mix agent. The stabilizer is composed of the following components in mass fraction, 1% sulfur, 2% divinylbenzene and 97% furfural oil.

[0043] The preparation process steps are as follows:

[0044] (1) Soak the 40-mesh desulfurization waste rubber powder in 50# base asphalt at 150°C for 30min to make it initially disperse and swell, and heat it in an oil bath;

[0045] (2) Homogenization treatment is carried out by using three-dimensional frequency conversion pre-shearing, and then the 50# base asphalt mixed with waste rubber powder is sheared and refined by a high-speed shearing emulsifier, the shearing speed is 3500rpm, and the ...

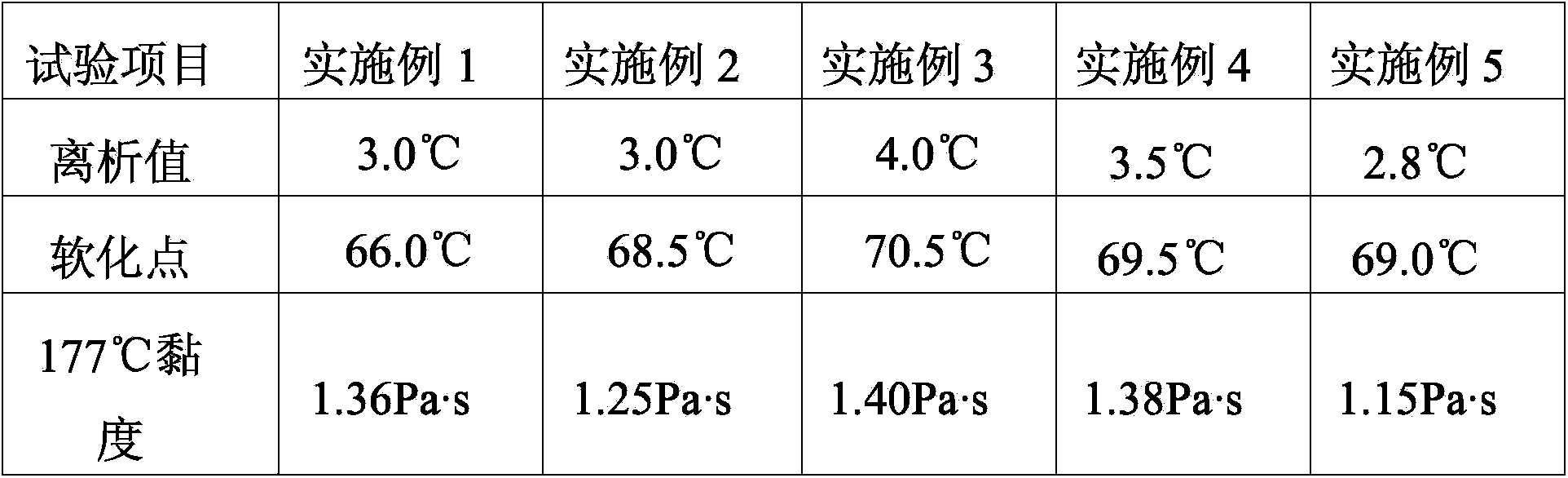

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com