Water-based environmental agate marble coating and preparation and construction methods thereof

A kind of imitation marble coating, environmental protection technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of difficult maintenance, single decorative effect, easy to fall off, etc., achieve good protection, solve radiation damage, and stable storage good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

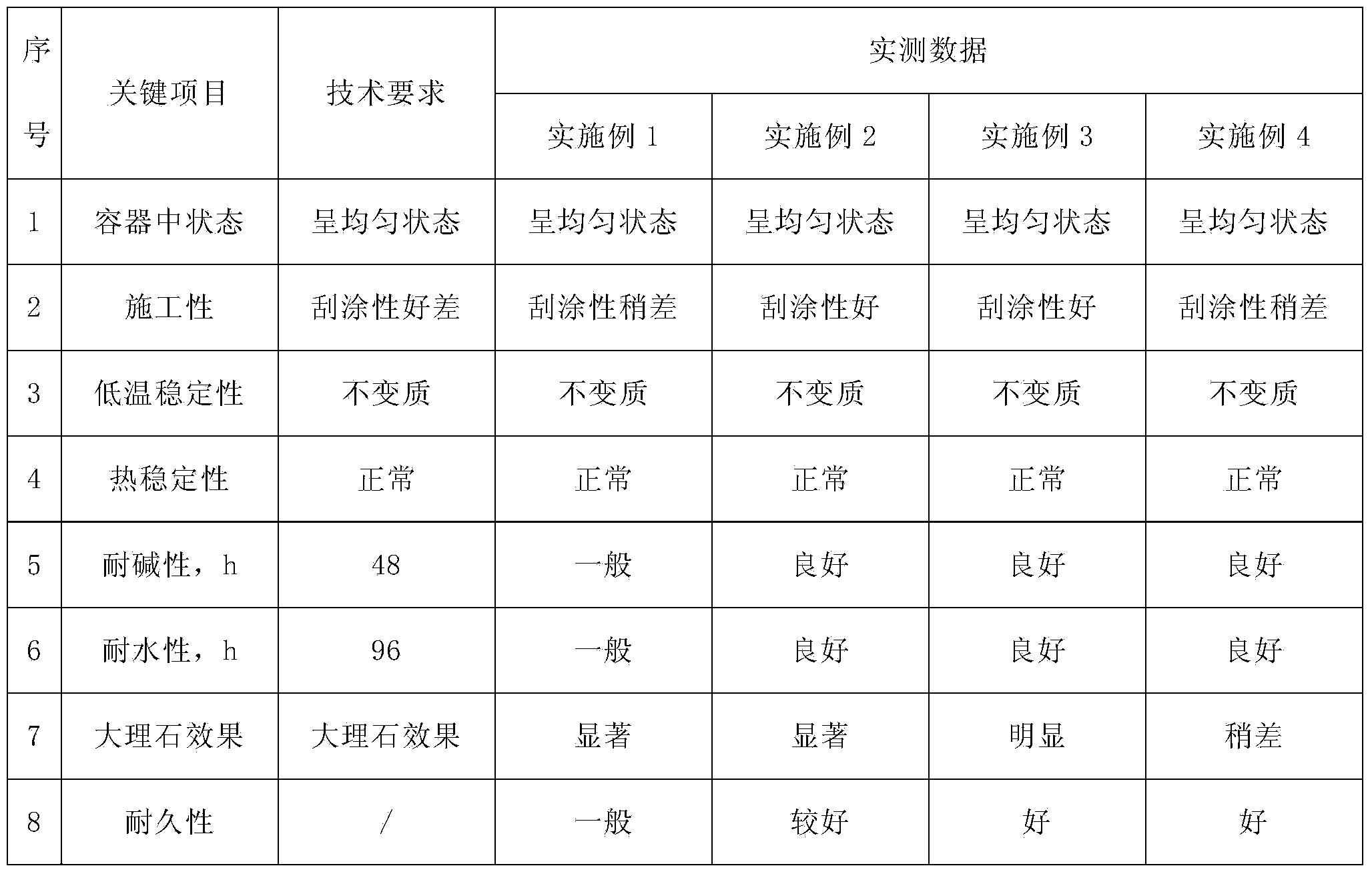

Examples

Embodiment 1

[0038] (1) Add 19.7 parts of water into the dispersion kettle, start the agitator, adjust the speed to 500rpm / min, add 0.20 parts of preservative A28S, 0.30 parts of defoamer SN80340.30 parts, and 0.20 parts of cellulose 250HBR under stirring, Increase the rotation speed to 1200rpm / min, disperse at high speed for 20min, until a transparent solution is formed, reduce the stirring speed to 500rpm / min, then add 0.10 parts of wetting agent WT, 1.0 parts of antifreeze ethylene glycol, and stir evenly;

[0039] (2) Increase the speed to 1200rpm / min, disperse at high speed for 10 minutes, add 70.0 parts of filler, continue to disperse at high speed for 30 minutes, and cool to room temperature;

[0040] (3) Grind to a fineness of less than 30 microns, add 65128.0 parts of emulsion, stir evenly, add thickener TT-9350.5 parts, stir evenly, and obtain water-based environmental protection imitation marble coating;

[0041] (4) After adding the color paste into the water-based environmenta...

Embodiment 2

[0049](1) Add 14.75 parts of water into the dispersion kettle, start the agitator, adjust the speed to 550rpm / min, add 0.175 parts of preservative K4, 0.25 parts of defoamer BYK-0240.25 parts, and 0.175 parts of cellulose ED-180 in turn under stirring. Increase the rotation speed to 1250rpm / min, disperse at high speed for 25min until a transparent solution is formed, reduce the stirring speed to 550rpm / min, then add 0.2 parts of dispersant SN50400, 0.125 parts of SNWET-990 wetting agent, and 0.75 parts of antifreeze propylene glycol part, stir well;

[0050] (2) Keep the speed at 550rpm / min, add 1.25 parts of AF-100 titanium dioxide from Zhenjiang Fanhua Titanium Industry Co., Ltd., disperse at a high speed of 1300rpm / min for 12 minutes, add 67.5 parts of filler calcium carbonate, continue to disperse at a high speed for 35 minutes, and cool to room temperature ;

[0051] (3) Grind to a fineness of less than 30 microns, add 651512.0 parts of synthetic resin emulsion, 0.25 par...

Embodiment 3

[0060] (1) Add 16.225 parts of water into the dispersion kettle, start the agitator, adjust the speed to 600rpm / min, add 0.065 parts of LXE preservative, 0.06 parts of R6400.06 parts of preservative defoamer B-5560.15 parts, cellulose PLUSS3300.125 parts, increase the speed to 1300rpm / min, disperse at high speed for 15min, until a transparent solution is formed, reduce the stirring speed to 500rpm / min, then add 0.6 parts of dispersant, wetting agent CF-110.175 parts, antifreeze 0.25 part of ethylene glycol, stir evenly;

[0061] (2) Keep the speed at 550rpm / min, add 2.75 parts of American Dupont R902+titanium dioxide, disperse at a high speed of 1500rpm / min for 15 minutes, add 4.5 parts of talc powder, 15 parts of wollastonite powder, and 43 parts of calcium carbonate, continue high-speed dispersion for 30 minutes, and cool to room temperature;

[0062] (3) Grind to a fineness of less than 30 microns, add 16.0 parts of American Dow Chemical Emulsion 420V emulsion, 0.25 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com