Gasification system for carbon-containing fuel

A gasification system and fuel gasification technology, applied in the manufacture of combustible gas, chemical industry, joint combustion mitigation, etc., can solve the problems of inability to efficiently use high-temperature water to discharge heat, and achieve the effect of carbon loss and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

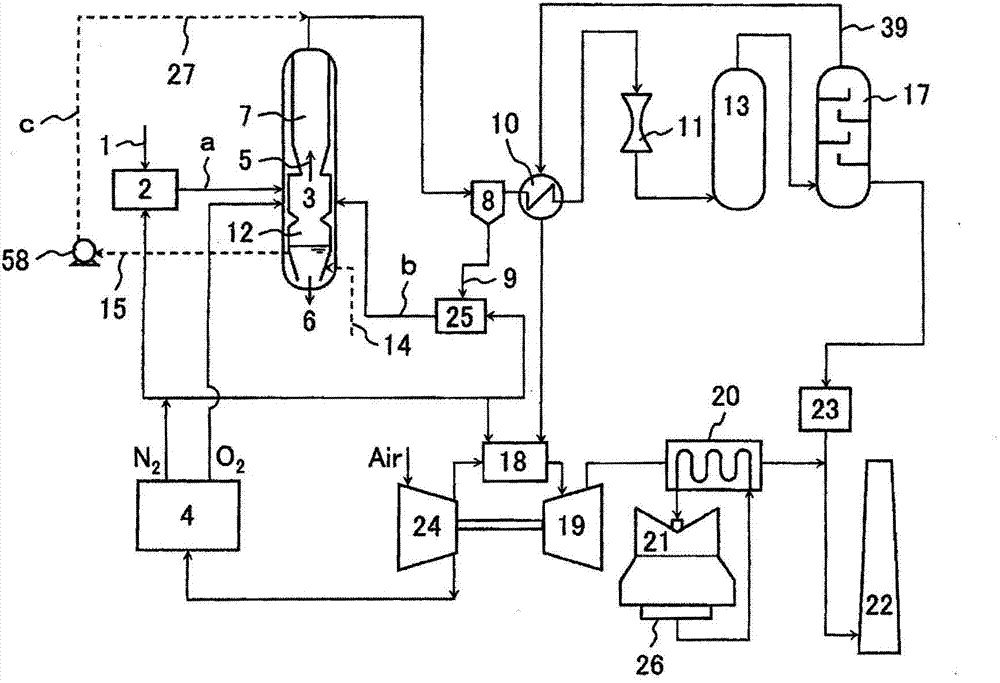

[0030] quote figure 1 , the combined coal gasification power generation facility equipped with the carbon-based fuel gasification system according to the first embodiment of the present invention will be described.

[0031] figure 1 The carbon-based fuel gasification system of the present example shown efficiently utilizes the sensible heat of high-temperature water generated in the cooling water storage part of the molten slag to cool the product gas obtained by gasifying the carbon-based fuel. Carbon-based fuel gasification system with miniaturized heat recovery unit.

[0032] Taking the case where coal is used as fuel and gas turbines and steam turbines are driven by generated gas as an example, use figure 1 A carbon-based fuel gasification system according to a first embodiment of the present invention will be described.

[0033] figure 1It is a system diagram showing the structure of a combined coal gasification power generation facility equipped with a carbon-based f...

Embodiment 2)

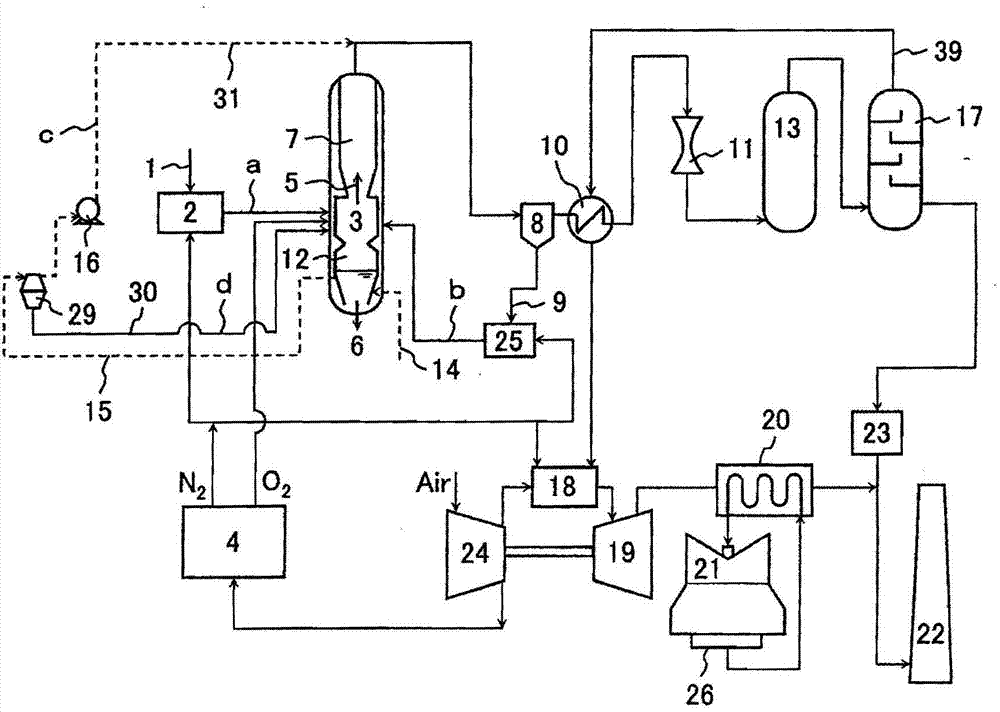

[0072] Next, use figure 2 A combined coal gasification power generation facility equipped with a carbon-based fuel gasification system according to a second embodiment of the present invention will be described. figure 2 The shown coal gasification combined power generation equipment equipped with the gasification system of the carbon-based fuel of this embodiment figure 1 The shown coal gasification combined power plant equipped with the carbon-based fuel gasification system of the first embodiment has the same basic structure, so the description of the common structure will be omitted, and the different structure will be described below.

[0073] exist figure 2 In the carbon-based fuel gasification system of the present embodiment shown, for the high-temperature water 15 heated by molten slag in the slag cooling water reservoir 12 directly below the gasification furnace 3, the slag cooling water The storage part 12 is extracted by the water supply system c and supplied ...

Embodiment 3)

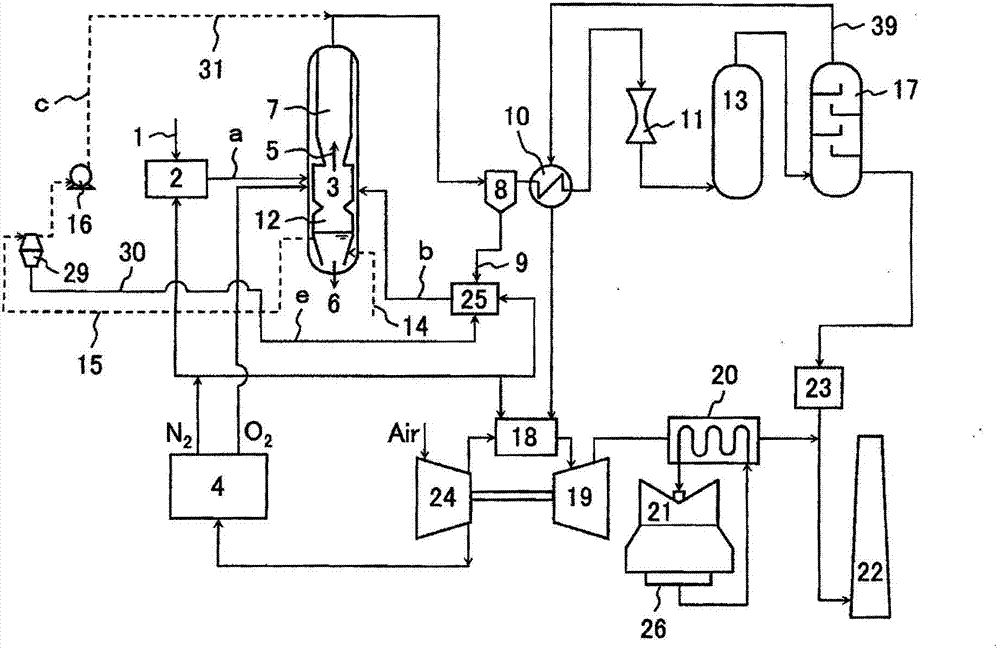

[0083] Next, use image 3 A combined coal gasification power generation facility equipped with a carbon-based fuel gasification system according to a third embodiment of the present invention will be described. image 3 The shown coal gasification combined power generation equipment equipped with the gasification system of the carbon-based fuel of this embodiment figure 1 The shown coal gasification combined power plant equipped with the carbon-based fuel gasification system of the first embodiment has the same basic structure, so the description of the common structure will be omitted, and the different structure will be described below.

[0084] exist image 3 In the carbon-based fuel gasification system of the present embodiment shown, for the high-temperature water 15 heated by molten slag in the slag cooling water reservoir 12 directly below the gasification furnace 3, the slag cooling water The storage part 12 is extracted by the water supply system c and supplied to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com