Method for producing low-carbon high-silicon manganese-silicon alloy from manganese-containing industrial waste slag through two-step method

A technology of industrial waste residue and manganese-silicon alloy, which is applied in the direction of improving process efficiency and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

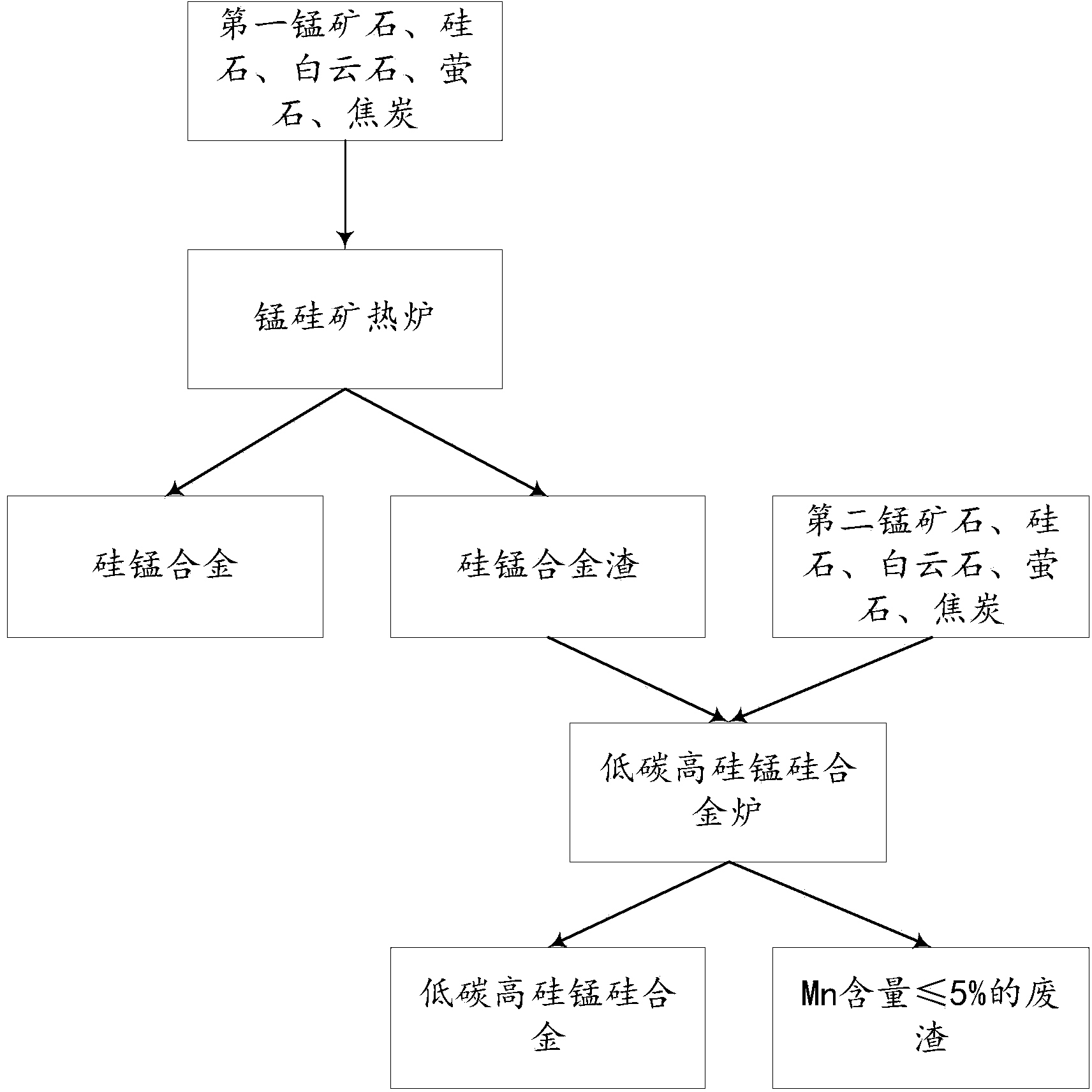

Method used

Image

Examples

Embodiment 1

[0018] 1) In the manganese-silicon submerged arc furnace, 100 parts of lump ore, 150 parts of Brazilian ore, 70 parts of sintered ore, 120 parts of West Asian ore, 150 parts of manganese-rich slag, 140 parts of coke, 80 parts of silica, 10 parts of dolomite, The mixture of 10 parts of fluorite is used as raw material for smelting, and the smelting temperature is 1500°C to obtain silicon-manganese alloy and silicon-manganese alloy slag;

[0019] 2) In a low-carbon high-silicon-manganese-silicon alloy furnace, use 140 parts of the silicon-manganese alloy slag, 80 parts of Australian lump ore, 150 parts of Siberian Australian express ore, 120 parts of manganese-rich slag, 1700 parts of silica, and 12 parts of dolomite , 60 parts of fluorite and 200 parts of coke are used as raw materials for smelting at a temperature of 1550°C to obtain a low-carbon high-silicon-manganese-silicon alloy.

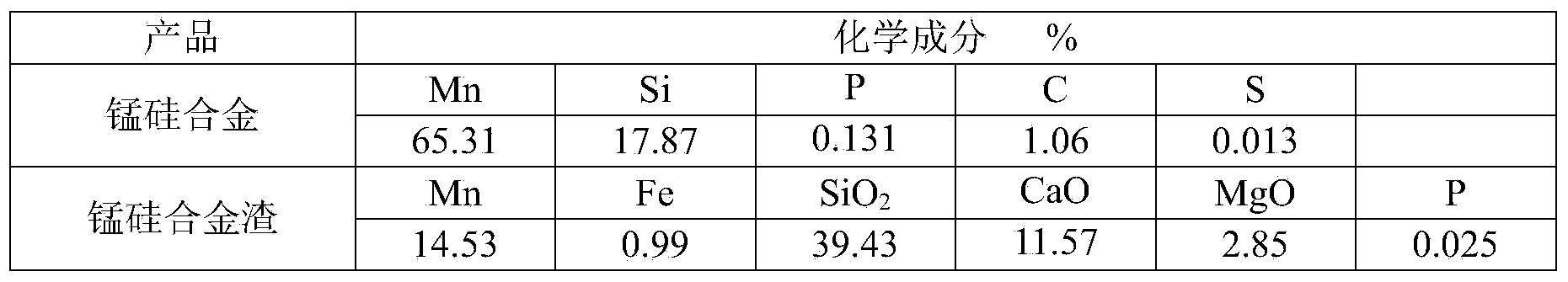

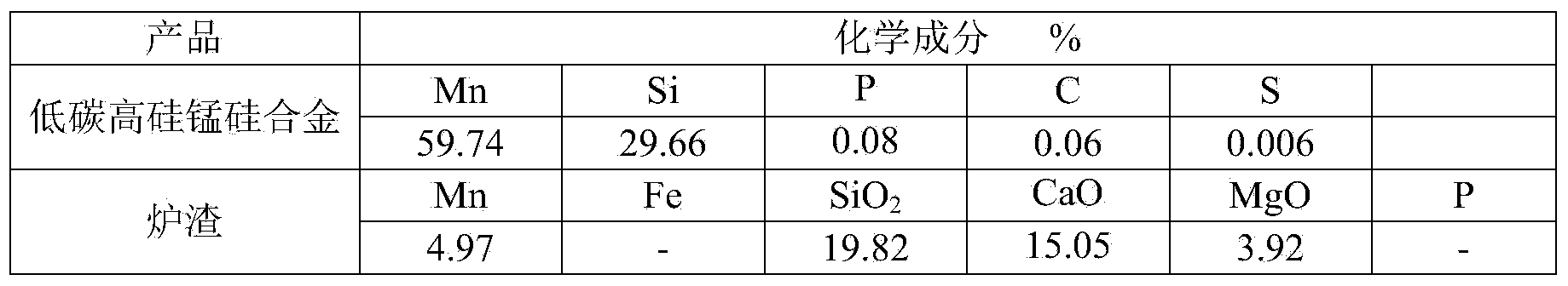

[0020] Step 1) The composition of the obtained silicon-manganese alloy and silicon-manganese...

Embodiment 2

[0025] 1) In the manganese-silicon submerged arc furnace, 120 parts of lump ore, 150 parts of Brazilian ore, 65 parts of sintered ore, 110 parts of West Asian ore, 150 parts of manganese-rich slag, 150 parts of coke, 80 parts of silica, 12 parts of dolomite, The mixture of 10 parts of fluorite is used as raw material for smelting, and the smelting temperature is 1550°C to obtain silicon-manganese alloy and silicon-manganese alloy slag;

[0026] 2) In a low-carbon high-silicon-manganese-silicon alloy furnace, use 130 parts of the silicon-manganese alloy slag, 75 parts of Australian lump ore, 180 parts of Siberian Australian express ore, 1200 parts of manganese-rich slag, 180 parts of silica, and 10 parts of dolomite , 60 parts of fluorspar and 2000 parts of coke are used as raw materials for smelting, and the smelting temperature is 1600 ° C to obtain a low-carbon high-silicon-manganese-silicon alloy.

[0027] Step 1) The composition of the obtained silicon-manganese alloy and ...

Embodiment 3

[0032] 1) In the manganese-silicon submerged arc furnace, 110 parts of lump ore, 160 parts of Brazilian ore, 70 parts of sintered ore, 110 parts of West Asian ore, 150 parts of manganese-rich slag, 145 parts of coke, 75 parts of silica, 10 parts of dolomite, A mixture of 12 parts of fluorite is used as raw material for smelting, and the smelting temperature is 1600°C to obtain silicon-manganese alloy and silicon-manganese alloy slag;

[0033] 2) In a low-carbon high-silicon-manganese-silicon alloy furnace, use 130 parts of the silicon-manganese alloy slag, 70-80 parts of Australian lump ore, 170 parts of Siberian Australian express ore, 130 parts of manganese-rich slag, 175 parts of silica, dolomite 10=parts, 55 parts of fluorite, and 210 parts of coke are used as raw materials for smelting, and the smelting temperature is 1650°C to obtain a low-carbon high-silicon-manganese-silicon alloy.

[0034] Step 1) The composition of the obtained silicon-manganese alloy and silicon-man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com