Preparation method of ionic liquid keratin spinning solutions

A technology of ionic liquid and keratin, which is applied in the field of regeneration and utilization of biomass resources, can solve the problems of low keratin strength, unrecyclable, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

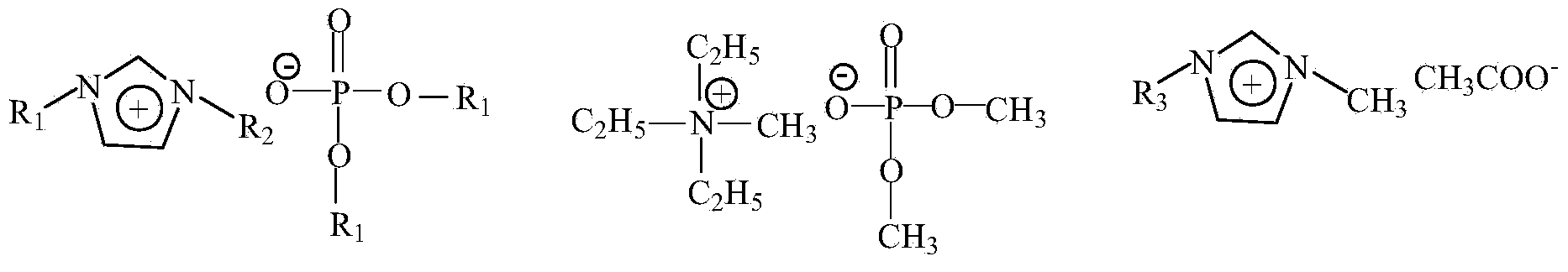

Method used

Image

Examples

Embodiment 1

[0012] Weigh 2.2050g of degreased and dried goat hair, add it to 32.1018g of 1,3-diethylimidazolium diethyl phosphate ionic liquid, then add 0.1660g of polyvinyl alcohol, and mechanically stir for 30min in an oil bath at 120°C to obtain Viscous keratin spinning solution (stirred with a glass rod to form filaments; extruded thin filaments with a syringe).

Embodiment 2

[0014] Weigh 2.6200g of degreased and dried yak hair, add it to 28.6327g of 1-butyl-3-methylimidazolium dimethyl phosphate ionic liquid, then add 0.1100g of polyacrylonitrile, and mechanically stir in an oil bath at 110°C for 40min , to obtain a viscous keratin spinning solution (stirred with a glass rod to form a filament; extrude a thin filament with a syringe).

Embodiment 3

[0016] Weigh 3.0326g of degreased and dried sheep wool, add it to 26.4700g of 1-butyl-3-methylimidazolium dibutyl phosphate ionic liquid, then add 0.1345g of natural hemp fiber, and mechanically stir in an oil bath at 130°C for 50min , to obtain a viscous keratin spinning solution (stirred with a glass rod to form a filament; extrude a thin filament with a syringe).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com