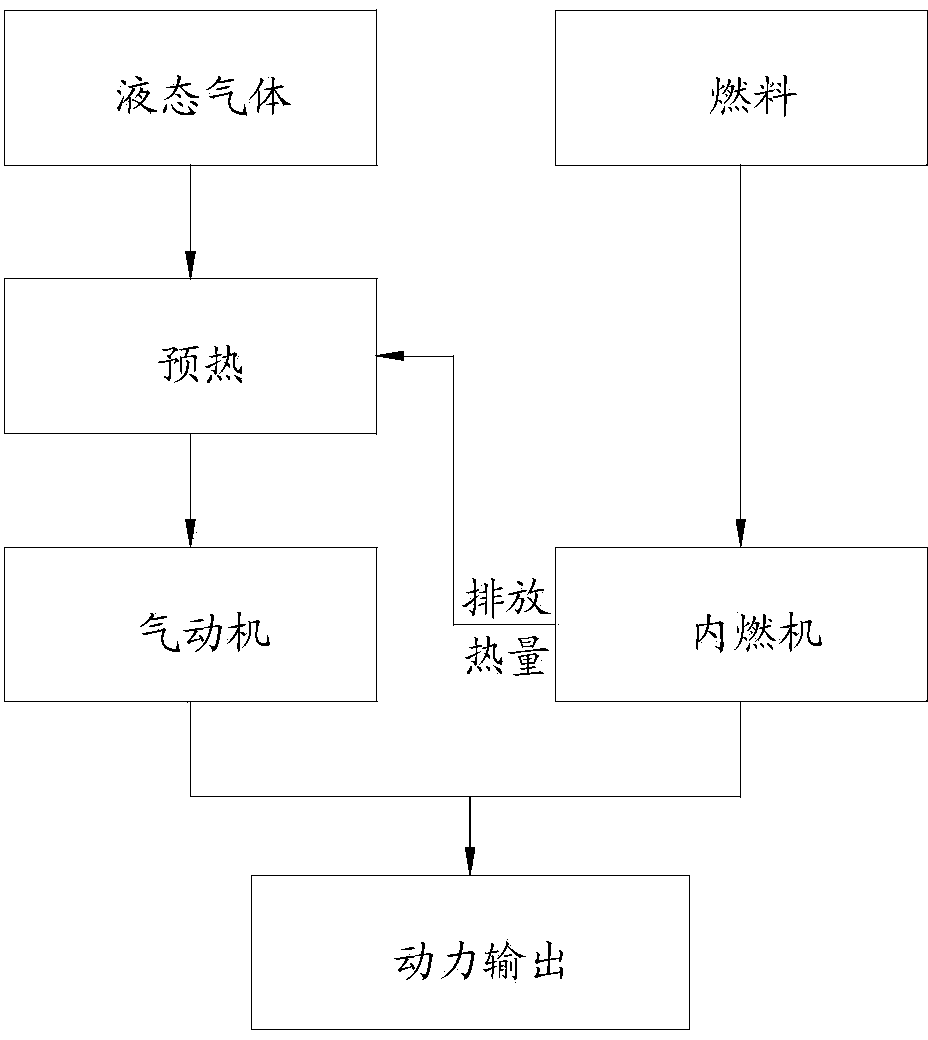

Hybrid power device and system and power output construction method adopting fuel and liquid gas

A hybrid power system and hybrid power technology, applied in the direction of pump devices, combustion engines, liquid variable displacement machinery, etc., can solve the problems of dust particles polluting the environment, the reuse rate is only 9%, and the consumption is large. loss, icing avoidance, and fuel usage reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

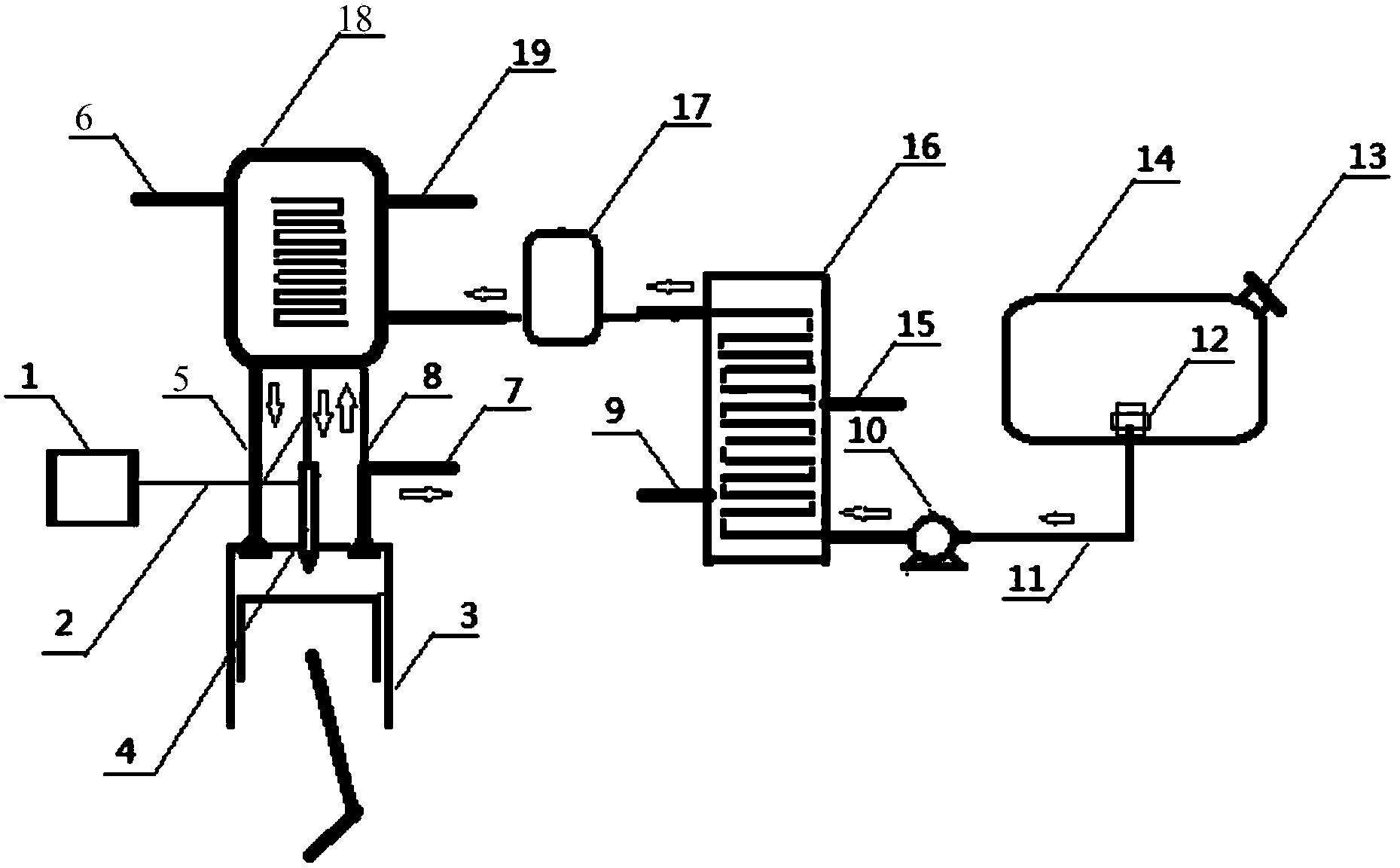

[0053] See figure 2 , which shows the principle diagram of the hybrid power system using liquid gas according to the first embodiment.

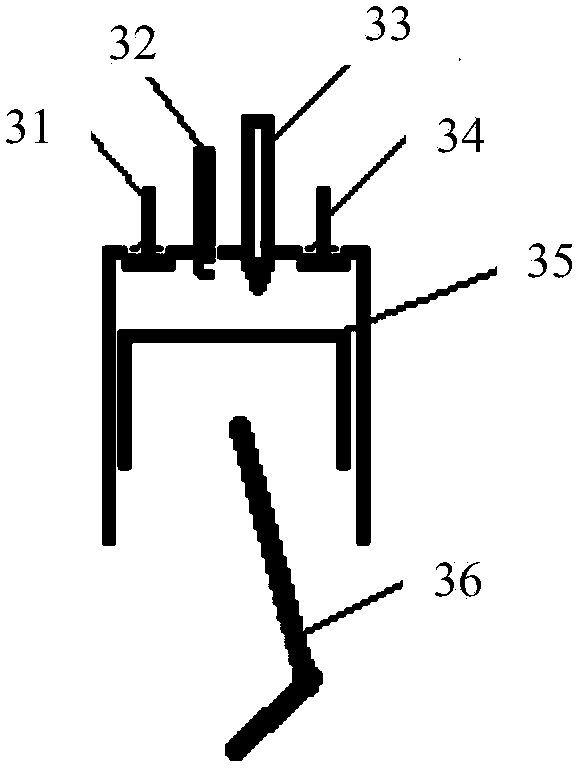

[0054] It should be noted that the power device used in the hybrid power system uses liquid gas and traditional fuel as the basic source of work, and is specifically composed of two main parts: an internal combustion engine cylinder and an air motor cylinder; among them, those skilled in the art can use existing Technology realizes the four-stroke internal combustion engine cylinder part, so in order to show the core design of the application more clearly, only the pneumatic part of the hybrid power system is shown in detail in the figure.

[0055] like figure 2 As shown, the adiabatic liquid storage tank 14 of the hybrid power system is used to store liquid nitrogen to fill and provide nitrogen as the "fuel" of the pneumatic motor. Specifically, the filling can be realized through the liquid filling port 13 opened on the adiabatic liquid ...

Embodiment 2

[0071] This embodiment is basically the same as the hybrid power system using fuel and liquid gas described in the first embodiment, and is further optimized on the basis of the first embodiment. See Figure 5 , which shows the schematic diagram of the hybrid power system using fuel and liquid gas according to the second embodiment. In order to clearly show the difference between the two, the same functional elements are marked with the same symbols in the figure.

[0072] Compared with the first embodiment, this solution has been improved in two aspects. First, the heat exchange preheater 18 also has a second heat source branch, which communicates in parallel with the internal combustion engine exhaust pipeline of the power plant, that is, its internal combustion engine exhaust inlet 20 and internal combustion engine exhaust outlet 21 communicate with the internal combustion engine. Exhaust pipeline, thereby further utilizing the exhaust heat of the internal combustion engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com