Method for testing carbonation depth of cement-base material

A cement-based material, carbonization depth technology, applied in the direction of material electrochemical variables, etc., can solve the problems of non-repeatability, limited sampling times, reading errors, etc., to achieve the effect of convenient and feasible testing, easy disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

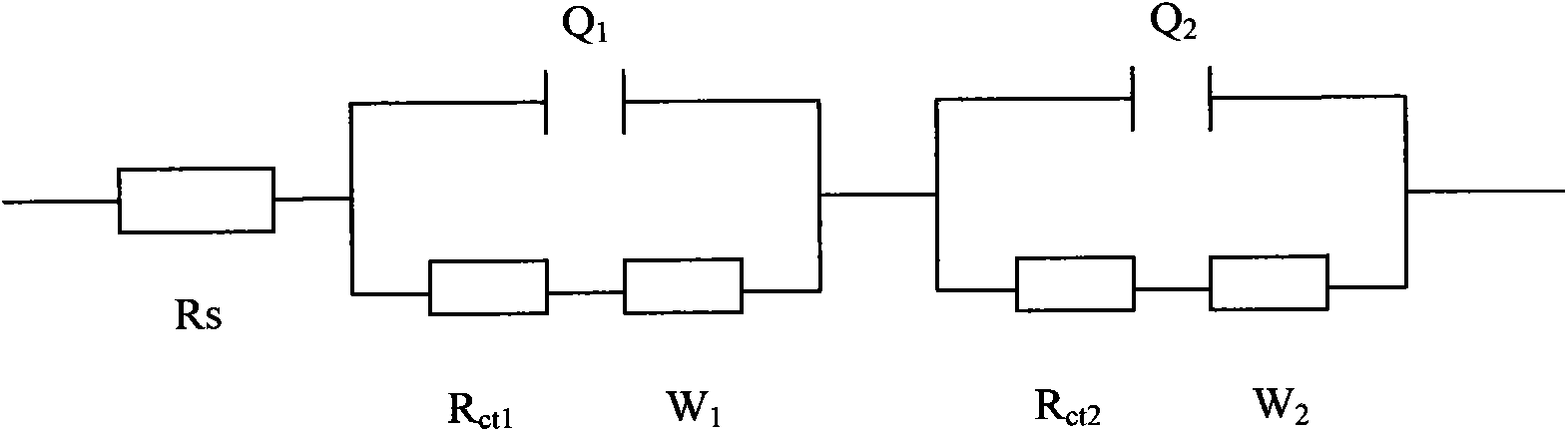

Method used

Image

Examples

Embodiment 1

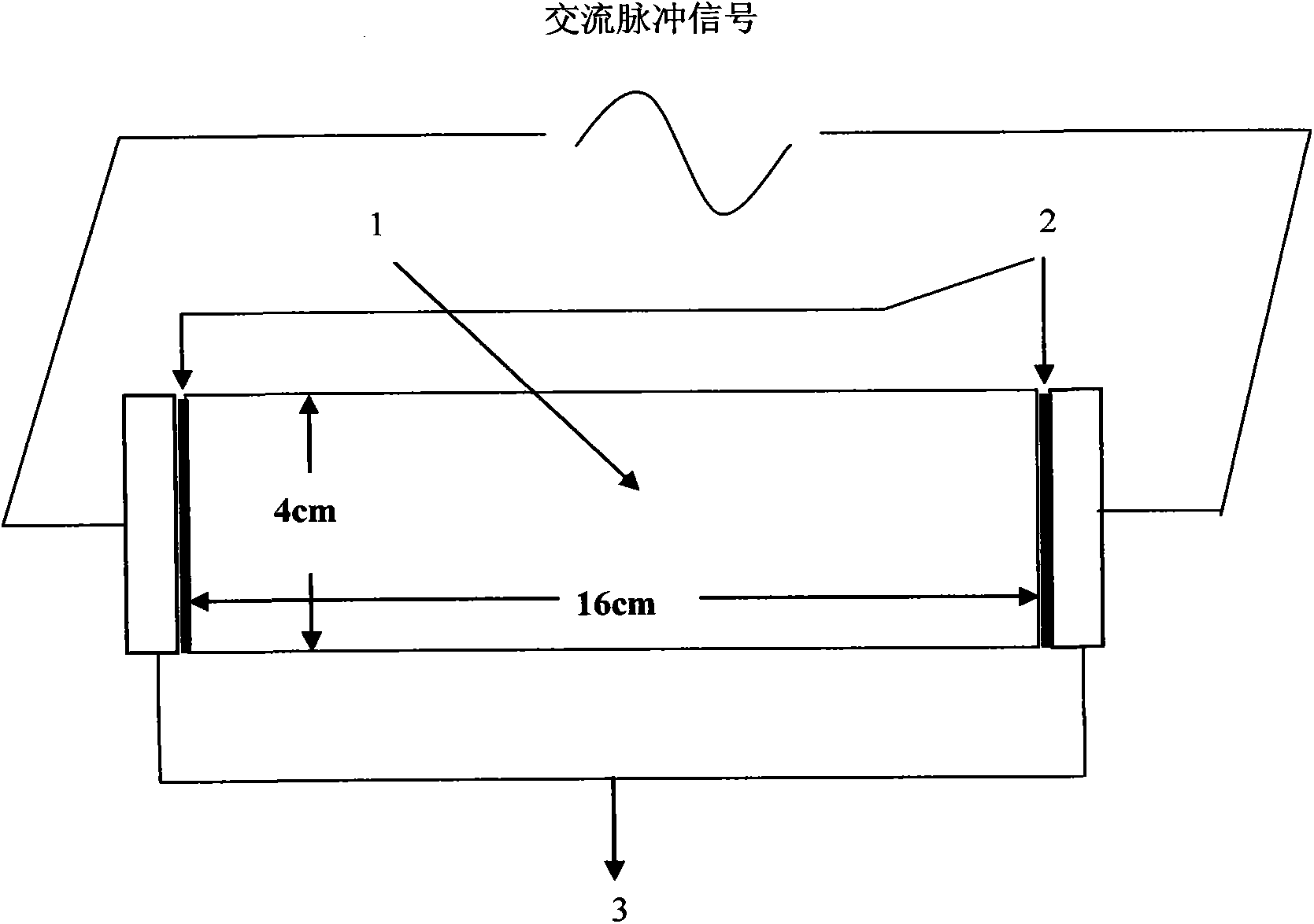

[0026] 1. Sample preparation: The 525-type composite Portland cement produced by Shenzhen Haixing Onoda Cement Co., Ltd. was prepared in a special mold (patent number: ZL 201120473976.2). The water-cement ratio of the cement paste test block was 0.25, 0.3, 0.4, 0.5, prepare 24 test pieces for each water-cement ratio, and the size of the test pieces is 160mm×40mm×40mm.

[0027] 2. End-unloading template: After the cement specimen is cured for 28 days, remove the 40mm×40mm electrode plates at both ends of the mold, and the remaining four 160mm×40mm high-insulation organic polymer plates are still sealed to the specimen.

[0028] 3. Carbonization: Put the mold after removing the electrode plate together with the test piece in the mold into the accelerated carbonization box. The carbon dioxide concentration in the box is 20%±3%, the relative humidity is 70%±5%, and the temperature is 20°C ±5°C.

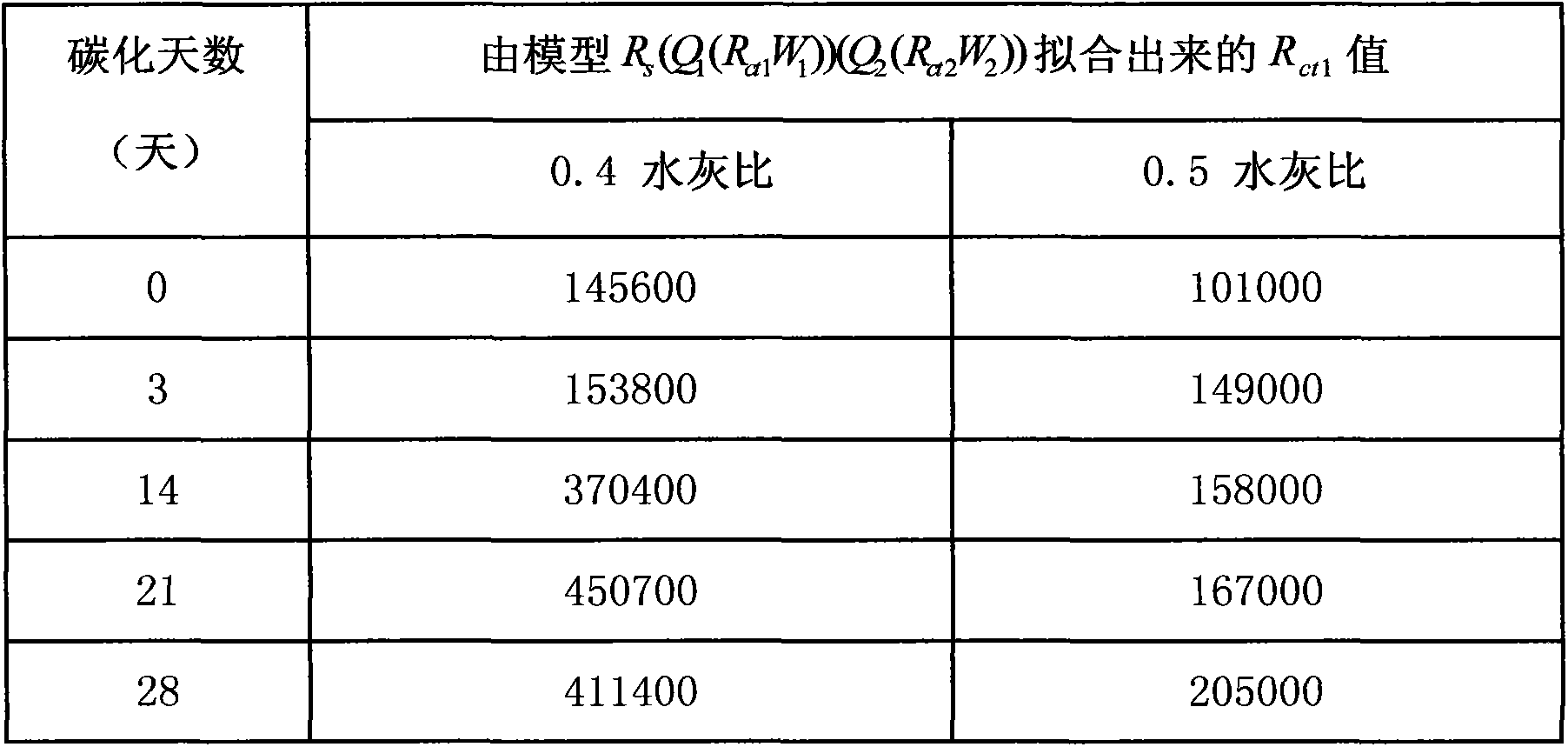

[0029] 4. Test: During the carbonization process, conduct impedance spectrum tests o...

Embodiment 2

[0043] The steps and methods adopted are as in Example 1, the difference is: 1) Test object: cement mortar material, water-cement ratio 0.40, mortar-sand ratio: 1:2, 1:3, 1:4; 2) Test days: 0 days, 3 days, 7 days, 14 days, 36 days, 60 days, 90 days, 120 days.

[0044] Table 51: Parameter R of mortar with mortar ratio of 2, 1:3, 1:4 at different carbonization days ct1 the value of

[0045]

[0046] Table 6 The measured value of the carbonation depth of the mortar 60 days ago.

[0047]

[0048] Table 7 Calculation of carbonation depth at 90 days and 120 days

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com