Negative-type photosensitive resin composition, resin film, and electronic component

A technology of photosensitive resin and composition, applied in optics, optomechanical equipment, photosensitive materials used in optomechanical equipment, etc., can solve the problem of insufficient pattern formation, development and adhesion, and achieve excellent pattern formation , Excellent solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0123] The preparation method of the negative photosensitive resin composition of this invention is not specifically limited, What is necessary is just to mix each component which comprises a negative photosensitive resin composition by a well-known method.

[0124]The method of mixing is not particularly limited, but it is preferable to mix a solution or a dispersion obtained by dissolving or dispersing each component constituting the negative photosensitive resin composition in a solvent. Thereby, a negative photosensitive resin composition is obtained in the form of a solution or a dispersion liquid.

[0125] The method of dissolving or dispersing each component which comprises a negative photosensitive resin composition in a solvent may follow a conventional method. Specifically, stirring with a stirrer and a magnetic stirrer, a high-speed homogenizer, a disperser, a planetary mixer, a twin-screw mixer, a ball mill, a three-roll machine, and the like can be used. In addit...

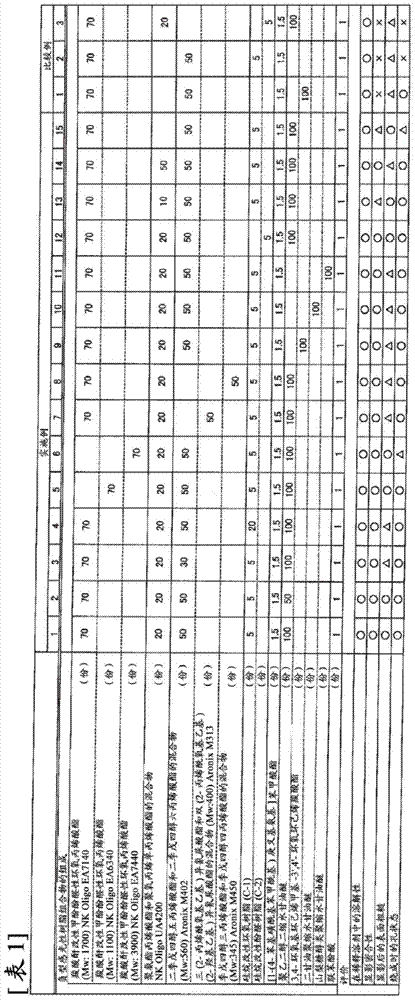

Embodiment 1

[0183] Add polyether-modified silicone oil (trade name "KP341", manufactured by Shin-Etsu Silicone Co., Ltd.) 300ppm to the following ingredients and mix and stir to dissolve them. The ingredients include:

[0184] Carboxyl group-containing resin compound (A1): 70 parts of carboxylic anhydride-modified cresol novolac epoxy acrylate (trade name "NK Oligo EA-7140", manufactured by Shin-Nakamura Chemical Co., Ltd., weight average molecular weight: 1700) was dissolved in propylene glycol mono 100 parts of the solution obtained by 30 parts of methyl ether acetate;

[0185] Carboxyl-free resin compound (A2): 20 parts of a mixture of urethane acrylate and polyoxypropylene monoacrylate (trade name "NK Oligo UA-4200", manufactured by Shin-Nakamura Chemical Co., Ltd.);

[0186] (Meth)acryloyl compound (B): 50 parts of a mixture of dipentaerythritol pentaacrylate and dipentaerythritol hexaacrylate (trade name "Aronix M402", manufactured by Toagosei Co., Ltd., weight average molecular wei...

Embodiment 2

[0195]The compounding quantity of the polyethylene glycol diglycidyl ether which is an epoxy group-containing crosslinking agent (E) was changed from 100 parts to 50 parts, except that, it operated similarly to Example 1, and obtained the negative photosensitive The resin composition was evaluated in the same manner. Table 1 shows the results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com