Processing method of instant dried sliced flavor razor clam

A processing method and flavor technology, applied in food preservation, food preparation, food science, etc., can solve problems such as increasing demand, and achieve the effect of increasing added value, high nutritional value, and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

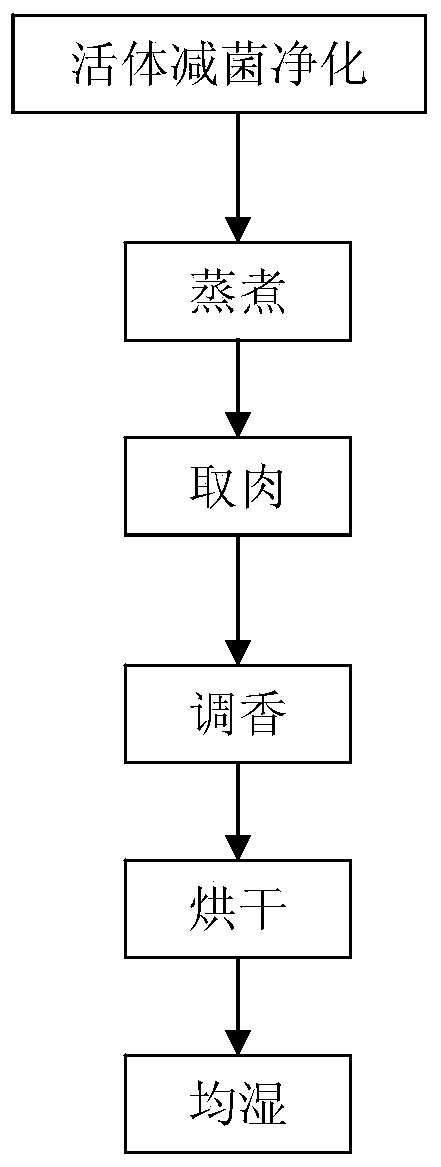

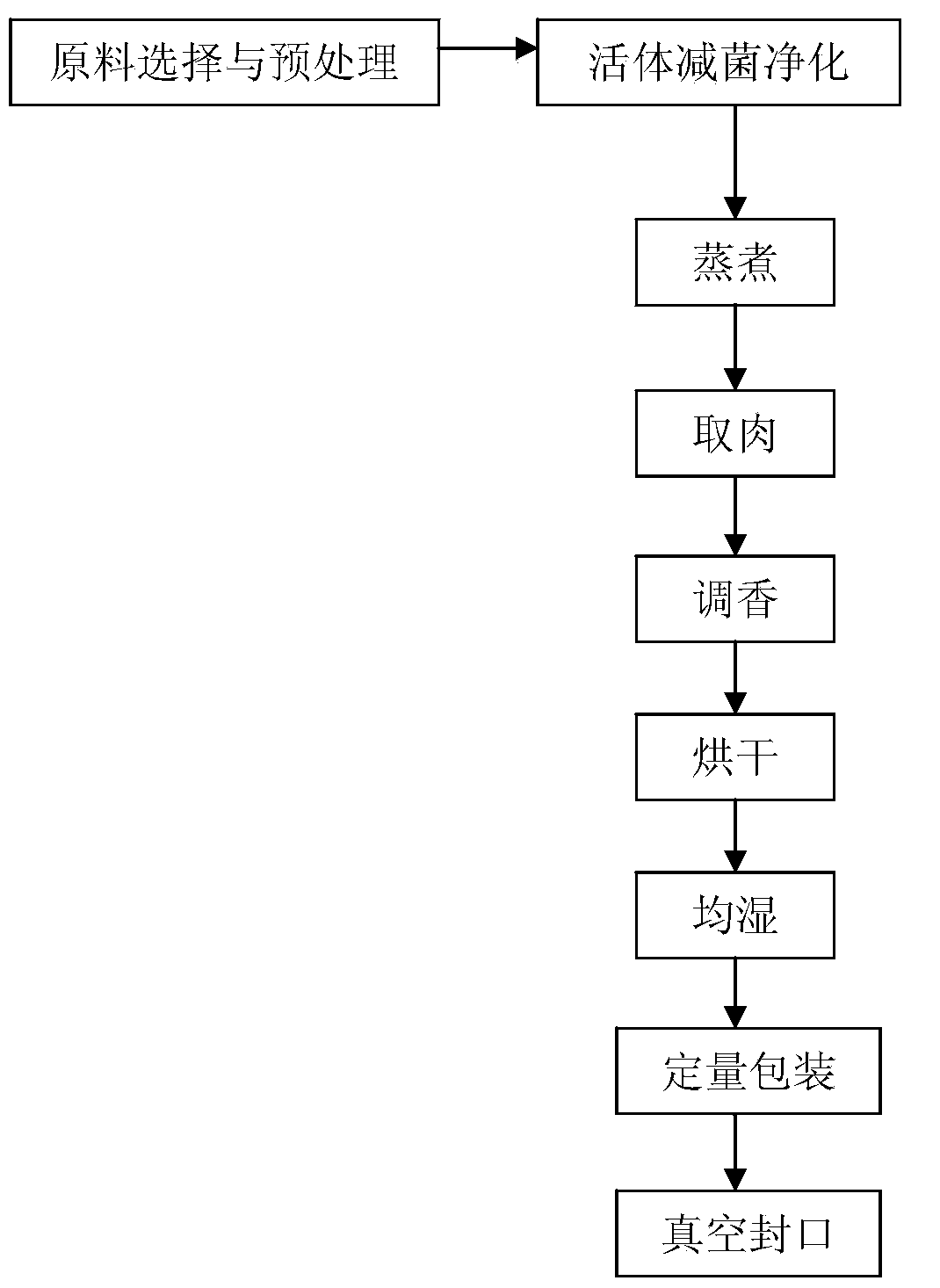

Image

Examples

Embodiment 1

[0029] Select individual fresh razor clams of the same size, remove the shells and dead and deteriorated products, and wash them with salt water at a temperature of about 20°C and a concentration of 2-3% until the surface of the raw materials is free of impurities. Put the washed razor clams in a purification pool containing chlorine dioxide for purification. The concentration of chlorine dioxide is 20mg / kg, the ratio of water to meat is 2:1, and the purification time is 4 hours each time. The ratio of 1:4 is placed in water at 95-100°C and boiled for 7 minutes. Take it out while it is hot and put it on the stainless steel sieve prepared in advance, filter the soup naturally, and quickly cool it in the air. After cooling, carefully remove the razor meat by hand, rinse with water and set aside. Taking the weight of the clam meat as the unit, add 0.5% salt, 0.5% monosodium glutamate, 1.5% sugar, 0.05% pepper, 0.5-3% cooking wine, 0.03% ginger juice, and 0.5% soy sauce to the re...

Embodiment 2

[0031] Select individual fresh razor clams of the same size, remove the shells and dead and deteriorated products, and wash them with salt water at a temperature of about 20°C and a concentration of 2-3% until the surface of the raw materials is free of impurities. The washed razor clams are put into a purification pool containing chlorine dioxide for purification. The concentration of chlorine dioxide is 25mg / kg, and the ratio of water to meat is 2.5:1. Generally, it needs to be purified 3 times, and the purification time is 4 hours each time. Put the purified razor clams in water at 95-100°C for 15 minutes according to the ratio of 1:5. Take it out while it is hot and put it on the stainless steel sieve prepared in advance, filter the soup naturally, and quickly cool it in the air. After cooling, carefully remove the razor meat by hand, rinse with water and set aside. Taking the weight of razor meat as the unit, add 1% salt, 0.8% monosodium glutamate, 5% sugar, 0.15% pepper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com