Preparation method of protective material for perfluoroisobutylene

A technology of perfluoroisobutylene and protective materials, which is applied to chemical instruments and methods, and other chemical processes, and can solve problems such as cumbersome processes and equipment hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

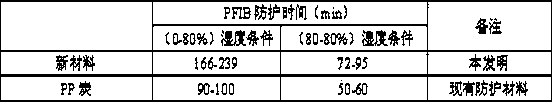

Examples

Embodiment 1

[0024] A perfluoroisobutylene protective material, comprising activated carbon as a carrier and an impregnating agent adsorbed by the activated carbon, the impregnating agent comprising 5% (weight) of Cu, 7% (weight) of TEDA, and 3% (weight) of Zn.

[0025] The preparation method is as follows:

[0026] (1) Add the impregnating agent of the above active components, that is, calculate the required weight of basic copper carbonate and zinc carbonate according to the content of the active components, add it into ammonia water, heat and melt to prepare an impregnating solution, and keep the temperature of the mixed solution 60°C, after the impregnating agent is fully dissolved, use the same amount of impregnating method, mix it with activated carbon evenly, and let it stand for 2 hours;

[0027] (2) The fluidized bed activation method is adopted, the activation temperature is 185°C, and the activation time is 40 minutes;

[0028] (3) The polyamine-based compound TEDA is adsorbed,...

Embodiment 2

[0030] A perfluoroisobutylene protective material comprising coconut shell activated carbon as a carrier and an impregnating agent adsorbed by activated carbon, the impregnating agent comprising 7% by weight of Cu, 4% by weight of TEDA, and 5% by weight of Zn .

[0031] The preparation method is as follows:

[0032] (1) Add the impregnating agent of the active component, that is, calculate the required weight of basic copper carbonate and zinc carbonate according to the content of the active component, add it into ammonia water, heat and melt to prepare the impregnating solution, and keep the temperature of the mixed solution at 70 ℃, when the impregnating agent is fully dissolved, mix it with activated carbon evenly by using the same amount of impregnating method, and let stand for 1.5h;

[0033] (2) The fluidized bed activation method is adopted, the activation temperature is 190°C, and the activation time is 35 minutes;

[0034] (3) The polyamine-based compound TEDA is ad...

Embodiment 3

[0036] A perfluoroisobutylene protective material, comprising activated carbon as a carrier and an impregnating agent adsorbed by the activated carbon, the impregnating agent comprising 3% (weight) of Cu, 8% (weight) of TEDA, and 0.1% (weight) of Zn.

[0037] The preparation method is as follows:

[0038] (1) Add the impregnating agent of the active component, that is, calculate the required weight of basic copper carbonate and zinc carbonate according to the content of the active component, add it into ammonia water, heat and melt to prepare the impregnating solution, and keep the temperature of the mixed solution at 65 ℃, when the impregnating agent is fully dissolved, use the same volume impregnation method, mix it with activated carbon evenly, and let it stand for 2 hours;

[0039] (2) The fluidized bed activation method is adopted, the activation temperature is 180°C, and the activation time is 30 minutes;

[0040] (3) The polyamine-based compound TEDA is adsorbed, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com