Deodorization adsorption material

An adsorption material and deodorization technology, which is applied in other chemical processes, dispersed particle separation, chemical instruments and methods, etc., can solve the problems that the protective performance of adsorption materials cannot meet the performance indicators and the performance of spherical activated carbon is degraded, so as to achieve mass production capacity, Weight reduction, uniform filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

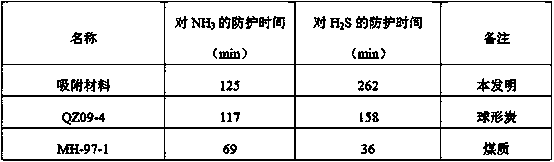

Image

Examples

Embodiment 1

[0027] An adsorption material for deodorization, which uses pitch-based spherical activated carbon as the carrier skeleton material, on which 7.7% (weight) of Cu, 4.2% (weight) of K are loaded, and the balance is activated carbon. Based on 100g of activated carbon, 7.7g of copper and 4.2g of potassium are loaded; then 30g of copper sulfate pentahydrate and 8g of potassium chloride are required as active components.

[0028] The preparation process mainly includes two steps of active component loading and activation.

[0029] 1. Solution preparation

[0030] The active components of the catalyst are mainly copper sulfate and potassium chloride. During the solution preparation process, the above active components are sequentially added to a certain amount of distilled water (the amount of distilled water is calculated according to the water capacity of the carrier) to ensure that each component Fully dissolved, the solution temperature is 60°C.

[0031] 2. Dipping

[0032] Us...

Embodiment 2

[0036] An adsorption material for deodorization, which uses pitch-based spherical activated carbon as the carrier skeleton material, on which 10.2% (weight) of Cu, 2.6% (weight) of K are loaded, and the balance is activated carbon. Based on 100g of activated carbon, 10.2g of copper and 2.6g of potassium are loaded; then 40g of copper sulfate pentahydrate and 5g of potassium chloride are required as active components.

[0037] The preparation process mainly includes two steps of active component loading and activation.

[0038] 1. Solution preparation

[0039] The active components of the catalyst are mainly copper sulfate and potassium chloride. During the solution preparation process, the above active components are sequentially added to a certain amount of distilled water (the amount of distilled water is calculated according to the water capacity of the carrier) to ensure that each component Fully dissolved, the solution temperature is 65°C.

[0040] 2. Dipping

[0041] ...

Embodiment 3

[0045] An adsorption material for deodorization, using pitch-based spherical activated carbon as the carrier skeleton material, on which 6.4% (weight) of Cu, 1.6% (weight) of K are loaded, and the balance is activated carbon. Based on 100g of activated carbon, 6.4g of copper and 1.6g of potassium are loaded; then 25g of copper sulfate pentahydrate and 3.1g of potassium chloride are required as active components.

[0046] The preparation process mainly includes two steps of active component loading and activation.

[0047] 1. Solution preparation

[0048] The active components of the catalyst are mainly copper sulfate and potassium chloride. During the solution preparation process, the above active components are sequentially added to a certain amount of distilled water (the amount of distilled water is calculated according to the water capacity of the carrier) to ensure that each component Fully dissolved, the solution temperature is 80°C.

[0049] 2. Dipping

[0050] Using...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com