Efficient coalescence-separation equipment for alkylating device

A technology of coalescence separation and alkylation, applied in liquid separation, separation methods, grease/oily substance/float removal devices, etc. Problems such as proprietary equipment for efficient separation of alkylation units have not yet been resolved to reduce short-circuit phenomena, ensure full utilization, and achieve rapid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

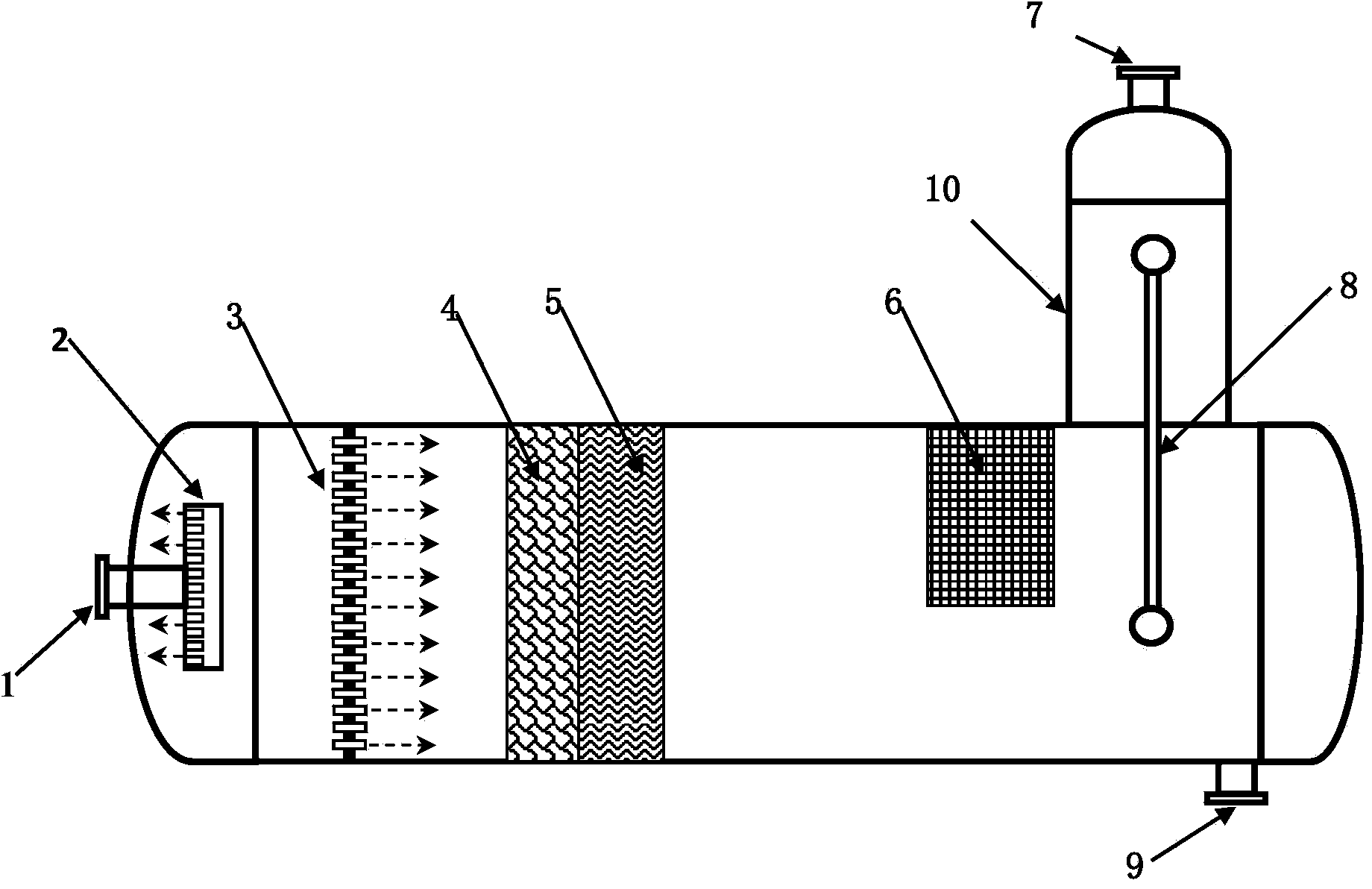

[0030] In a 200,000-ton / year alkylation project in Shandong Province, the high-efficiency coalescing separation equipment of the present invention is used to separate the extracted refrigerant-propane and water.

[0031] Its specific operation process and effect are described as follows:

[0032] 1. Operating conditions of propane dehydration equipment

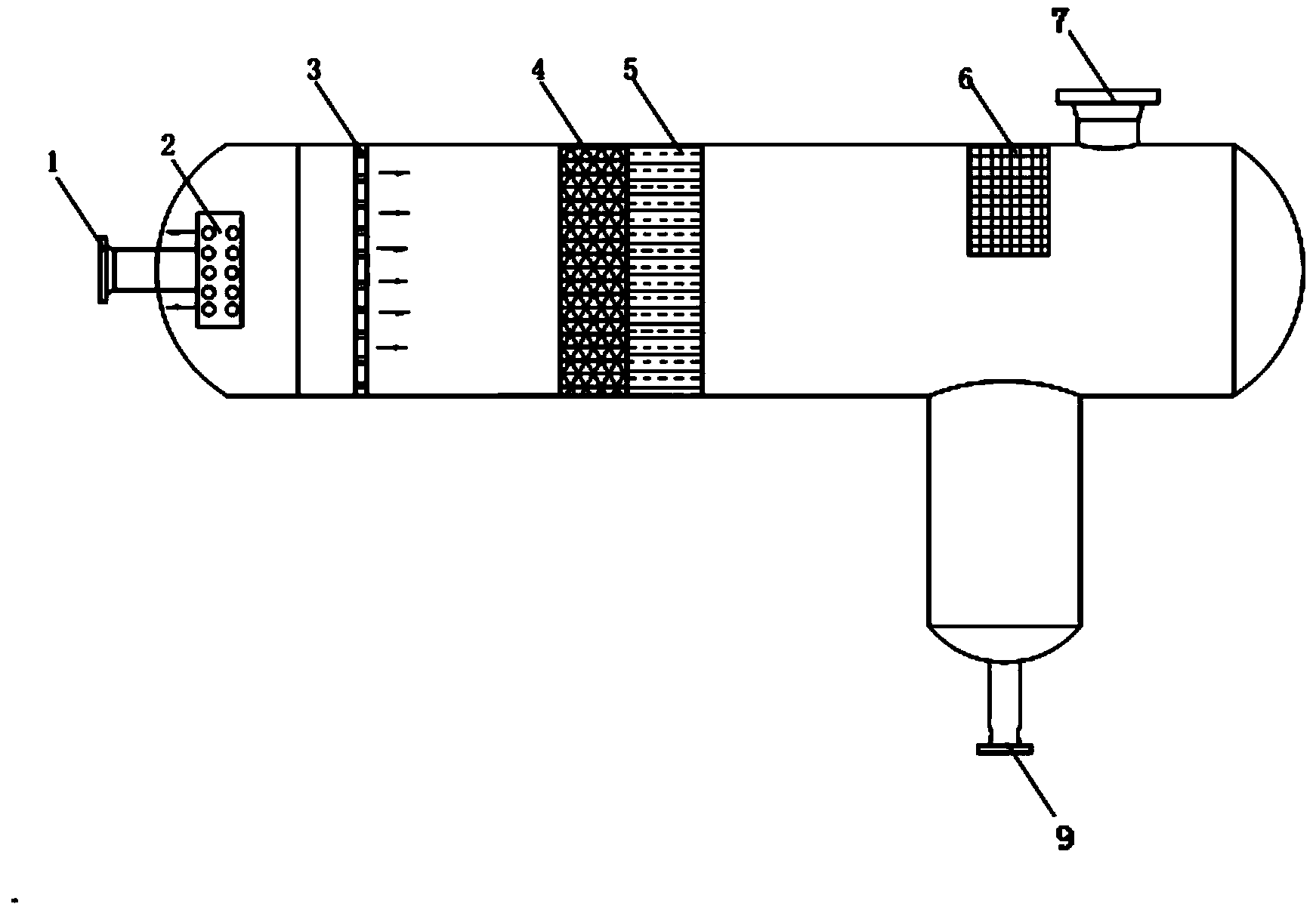

[0033] The main components are: volume flow, 95% propane, 5% water; the processing capacity is propane 1063kg / h, water 72kg / h, operating temperature 52 ℃, operating pressure 1.75MPa. as attached figure 2 As shown in the figure, since the content of the oil phase is much larger than that of the water phase, it belongs to the dehydration process in the oil, so the oil collecting chamber at the top of the casing is changed to a water bag at the bottom of the casing, and the water phase outlet is set on the water bag.

[0034] 2. Implementation process

[0035] The mixture of propane and water enters the high-efficiency coales...

Embodiment 2

[0041] In a 160,000-ton / year industrial isooctane project in Zhejiang Province, the high-efficiency coalescence separation equipment of the present invention is used in the acid settling tank to separate the oil phase-mixed hydrocarbons and concentrated sulfuric acid.

[0042] Its specific operation process and effect are described as follows:

[0043] 1. Operating conditions of acid settling tank

[0044] Table 1 Design physical parameters of acid settling tank

[0045] Material name

Mixed hydrocarbons, wash water

unit

Oil phase flow

77113

kg / h

oil phase density

554

kg / m

Acid phase flow

256116

kg / h

Acid phase density

1840

kg / m

Operating temperature max / normal / min

(requires cooling)

℃

Operating pressure max / normal / min

0.6

MPa(G)

[0046] 2. Implementation process

[0047] This embodiment can refer to the appendix figure 2 , the mixture of mixed hydrocarbon and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com