Preparation method for microporous aluminum foil and microporous aluminum foil prepared by preparation method

An aluminum foil and microporous technology, which is applied in the field of lithium-ion batteries, can solve the problems of insignificant improvement in electronic conductivity, no improvement in ionic conductivity, and decreased mechanical strength of aluminum foil, so as to improve ionic conductivity, avoid unbalanced conductivity and Affects the mechanical properties of aluminum foil and improves the electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

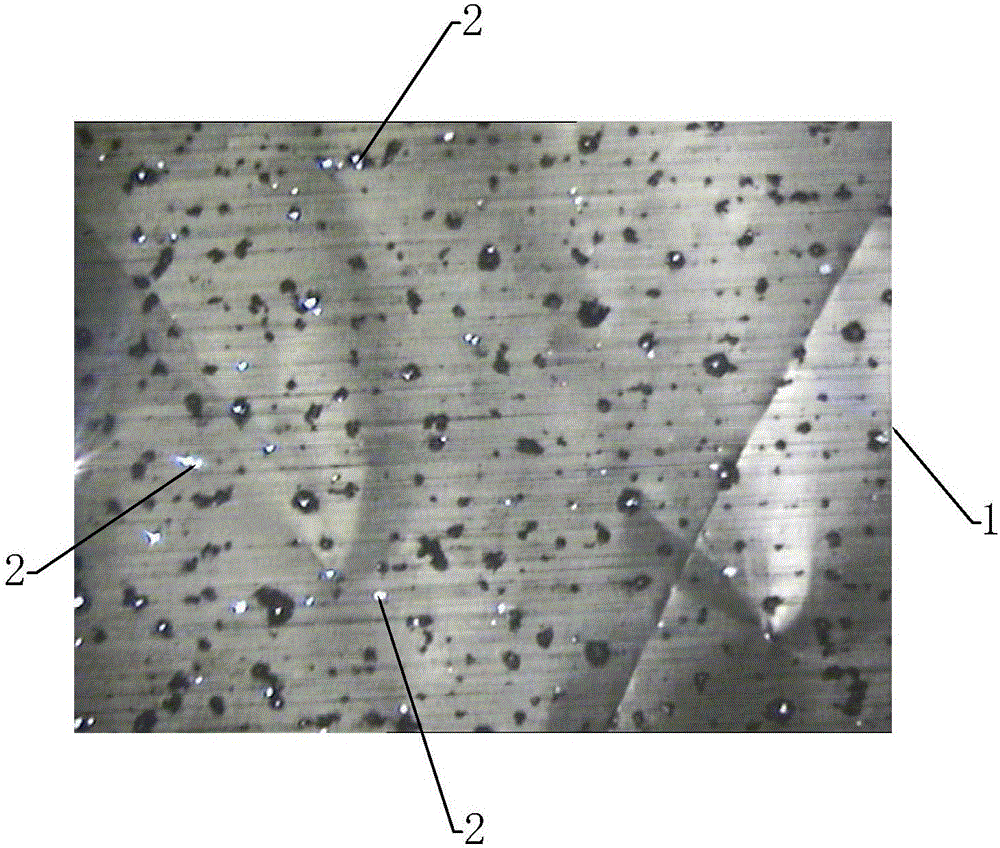

Image

Examples

Embodiment 1

[0023] A preparation method of microporous aluminum foil, adopting the following steps:

[0024] (1) Add 21g of carbon nanotubes and 5g of polyvinylpyrrolidone into 1L of deionized water and mix evenly, use a grinder to grind for 180min, disperse to obtain a slurry, pass the slurry through a 100-mesh sieve, and set aside;

[0025] (2) Evenly coat the sieved slurry prepared in step (1) on an aluminum foil with a thickness of 5um, control the coating thickness to 10um, and dry the coating for 5min;

[0026] (3) Ultrasonic cleaning is performed on the coating layer dried in step (2) with cleaning agent water to obtain a clean microporous aluminum foil.

[0027] For the microporous aluminum foil prepared by the above microporous aluminum foil preparation method, use CCD to measure and characterize the pore diameter of the microporous aluminum foil obtained is 0.5-5um, the porosity is 5%, and the air permeability is 850s / 100cc.

Embodiment 2

[0029] A preparation method of microporous aluminum foil, adopting the following steps:

[0030] (1) Add 40g of acetylene black (carbon black), 5g of polyvinylpyrrolidone, and 15g of polyaspartic acid into 1L of deionized water and mix evenly, use a grinder to grind for 60min, disperse to obtain a slurry, and pass the slurry through 50 mesh sieve, spare;

[0031] (2) Evenly coat the sieved slurry prepared in step (1) on an aluminum foil with a thickness of 50 um, control the coating thickness to 5 um, and dry the coating for 60 min;

[0032] (3) Ultrasonic cleaning is performed on the coating layer dried in step (2) with water to obtain a clean microporous aluminum foil.

[0033] For the microporous aluminum foil prepared by the above microporous aluminum foil preparation method, the pore diameter of the obtained microporous aluminum foil is 50-300um, the porosity is 15%, and the air permeability is 350s / 100cc.

Embodiment 3

[0035] A preparation method of microporous aluminum foil, adopting the following steps:

[0036] (1) Add 21g of expanded graphite and 10g of polyaspartic acid into 1L of deionized water and mix evenly, use a grinder to grind for 600min, disperse to obtain a slurry, pass the slurry through a 300-mesh sieve, and set aside;

[0037] (2) Evenly coat the sieved slurry prepared in step (1) on an aluminum foil with a thickness of 27um, control the coating thickness to 15um, and dry the coating for 32min;

[0038] (3) ultrasonically cleaning the coating layer dried in step (2) with water to obtain a clean microporous aluminum foil.

[0039] For the microporous aluminum foil prepared by the above microporous aluminum foil preparation method, the microporous aluminum foil obtained has a pore diameter of 10-200um, a porosity of 12%, and an air permeability of 550s / 100cc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com