Nucleating agent modifying and preparing method of high-performance polypropylene

A technology of nucleating agent and polypropylene, which is applied in the field of nucleating agent modification and preparation of high-performance polypropylene, which can solve the problems of difficult dispersion, uneven nucleation, large amount of nucleating agent, etc., and achieve excellent performance, The effect of obvious nucleation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

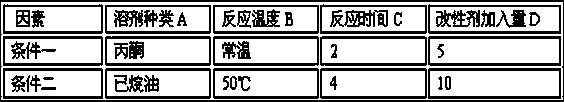

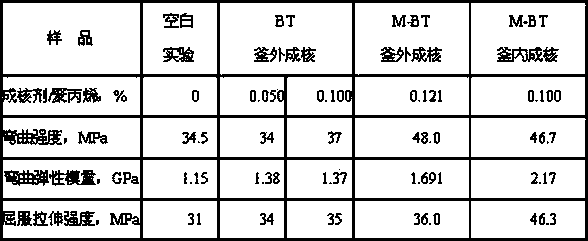

[0014] Reaction raw materials: use high-purity nitrogen and high-purity hydrogen with a purity of ≥99.99%, and use triethylaluminum (AlEt 3 ) as co-catalyst for polypropylene catalyst (HDC), 0.1mol / L hexane as external electron donor, acetone or hexane oil as solvent.

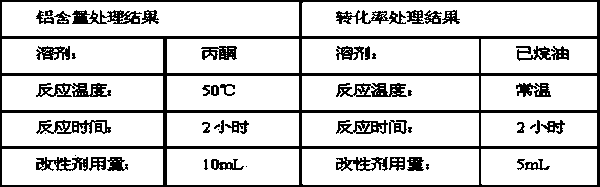

[0015] 1g of nucleating agent, appropriate amount of modifier, 30mL of acetone solvent, stirred for 2h, heated at 50°C to remove the solvent under reduced pressure to obtain a dry white solid, added 20mL of hexane, stirred at room temperature for 10min, filtered, then added hexane 20mL, stirred at room temperature for 10min, and repeated 5 times in total. The purpose was to wash off the excess modifier that did not participate in the reaction, and no aluminum was detected in the filtrate of the 5th time. White powder after drying.

[0016] The purpose of washing off the excess unreacted modifier is to ensure that no additional alkylaluminum is introduced during polymerization, so as to compare the accuracy wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com