High-temperature polymer-based electromagnetic shielding functionally gradient material

A high-temperature-resistant polymer and gradient functional material technology, applied in the field of polymer-based electromagnetic shielding functional materials, can solve the problems of not providing the effect or embodiment of material electromagnetic shielding, not involving high-temperature resistant resin matrix, and high processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Prepare the polymer solution, the specific process is as follows: put 6g PEI and 300m1DMF into a three-necked flask with a stirring device, and stir at room temperature until the PEI is completely dissolved at a stirring speed of 300 rpm. This solution is called Lp-1; preparation polymer / carbon-based conductive filler A solution, specific process is as follows: in the there-necked flask with stirring device, half of the solution Lp-1 is filled, the graphene of 0.6g (10wt%) is added wherein in Stir at room temperature for 300 minutes, and this solution is called La-1; prepare the polymer / metal conductive filler B solution, the specific process is as follows: put the remaining solution Lp-1 in a three-necked flask with a stirring device, add 2.4g (40wt%) nickel powder was stirred at room temperature for 300 minutes, and this solution was called Lb-1.

[0035] Preparation of high-temperature-resistant polymer-based electromagnetic shielding gradient functional materials, the...

Embodiment 2

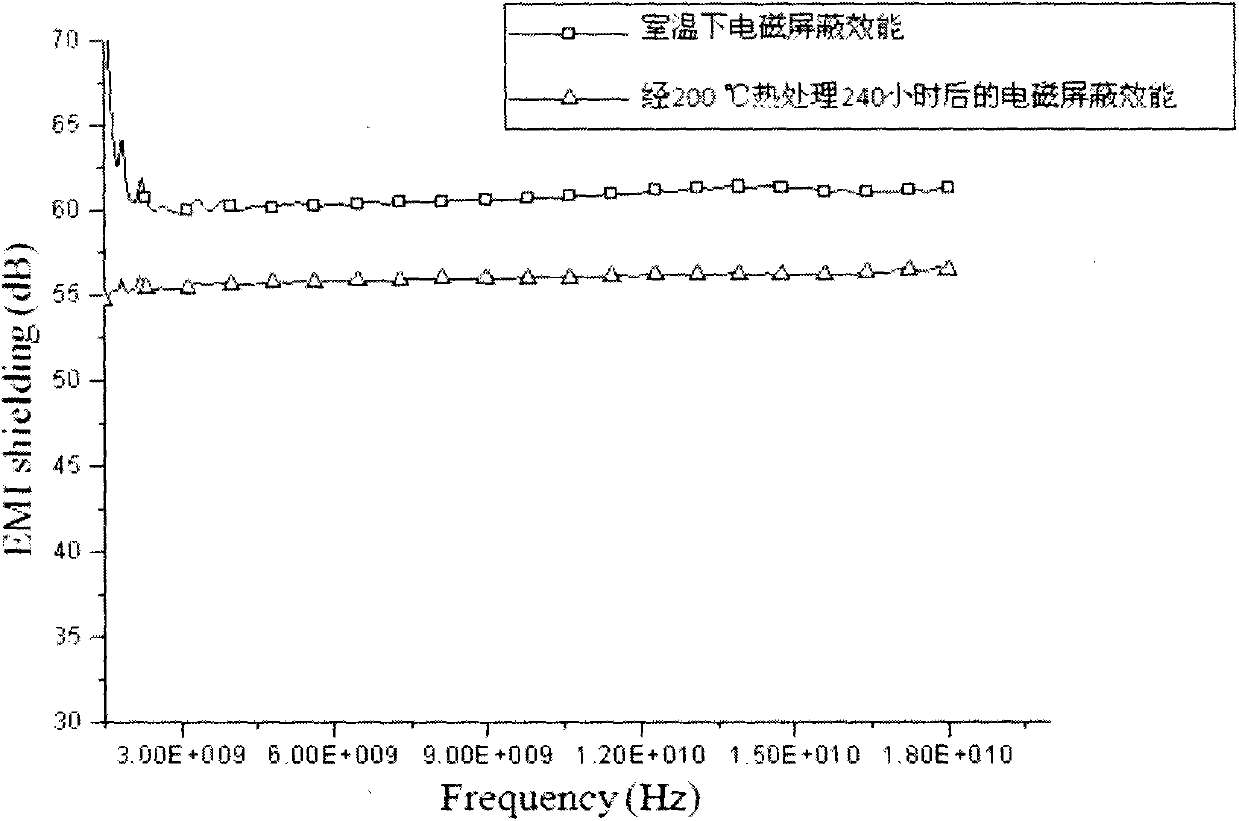

[0037] The method is as in Example 1, replacing graphene with carbon nanotubes. The electromagnetic shielding effectiveness of the high temperature resistant polymer-based electromagnetic shielding gradient functional material and the electromagnetic shielding effectiveness after heat treatment at 200°C for 240 hours are listed in Table 1.

Embodiment 3

[0039] The method is as in Example 1, replacing graphene with graphite. The electromagnetic shielding effectiveness of the high temperature resistant polymer-based electromagnetic shielding gradient functional material and the electromagnetic shielding effectiveness after heat treatment at 200°C for 240 hours are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com