Heat treatment micro-deformation control method for wind power equipment gear main shaft

A technology of wind power equipment and control method, applied in heat treatment process control, heat treatment furnace, heat treatment equipment and other directions, can solve the problems of weakening the spline strength and affecting the transmission quality of the gear spindle, so as to improve the mechanical performance, prolong the service life, and ensure the transmission. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

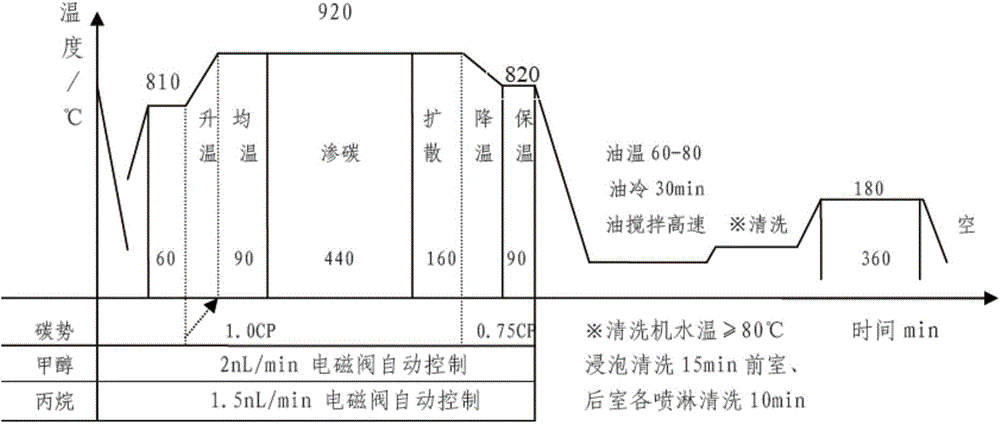

[0024] refer to figure 1 , the present invention provides a heat treatment micro-deformation control method for a wind power equipment gear main shaft, comprising the following steps:

[0025] a. Preheat the gear spindle, heat the gear spindle to 800°-850° and keep it warm for 40min-90min, then raise the temperature to 900°-940° and keep it warm for 80min-120min; preferably, heat the gear spindle to 810° and keep it warm for 60min , then heat up to 920 ° and keep warm for 90min;

[0026] b. Carburizing treatment, carburizing treatment is carried out at 900°-940°, the concentration of carbon dioxide is controlled between 0.8%-1.2%, and the continuous carburizing time is 400min-500min; preferably, carburizing is carried out at 920° Treatment, control the carbon dioxide concentration at 1%, and the continuous carburizing time is 440min; then the gear ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com